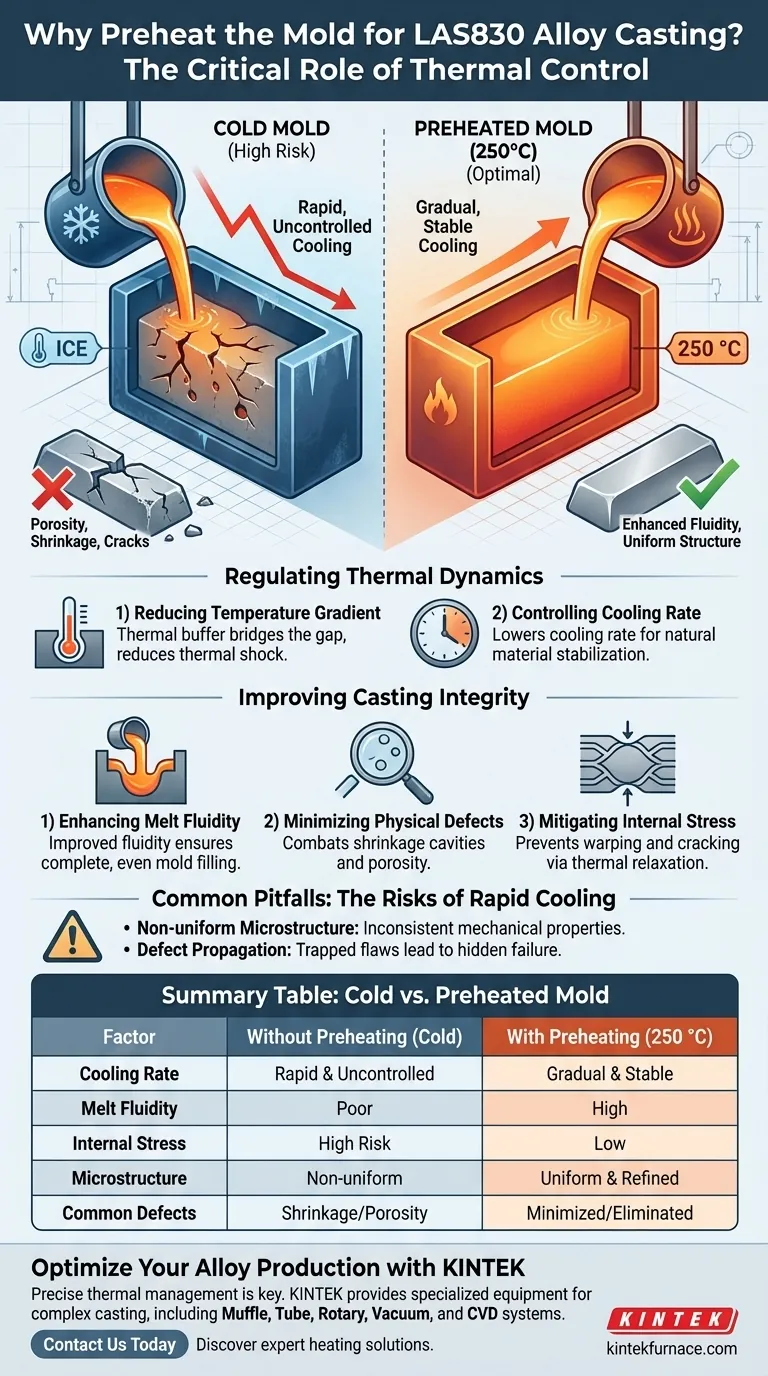

Preheating the mold is a critical requisite for successfully casting Mg-8Li-3Al-0.3Si (LAS830) alloy ingots. By bringing the mold temperature up, typically to 250 °C, you bridge the thermal gap between the container and the molten metal, which is the primary defense against structural failure during solidification.

Preheating significantly lowers the cooling rate by reducing the temperature difference between the melt and the mold. This thermal control is the single most effective way to enhance fluidity, minimize internal stresses and defects, and guarantee a uniform microstructure in the final alloy blank.

Regulating Thermal Dynamics

Reducing the Temperature Gradient

When molten metal enters a cold mold, the temperature difference is extreme. This shock drives rapid, uncontrolled heat transfer.

Preheating the mold to 250 °C acts as a thermal buffer. It reduces the severity of the temperature drop the moment the liquid alloy touches the mold walls.

Controlling the Cooling Rate

The quality of an ingot is often dictated by how fast it freezes. A cold mold forces the metal to solidify too quickly.

By preheating, you intentionally lower the cooling rate. This provides a more gradual transition from liquid to solid, allowing the material to stabilize naturally.

Improving Casting Integrity

Enhancing Melt Fluidity

For the LAS830 alloy to form a proper ingot, the metal must flow smoothly into every part of the mold before freezing.

A preheated mold maintains the metal's temperature for a fraction longer. This improved melt fluidity ensures the mold is filled completely and evenly.

Minimizing Physical Defects

Rapid cooling often traps gas or leaves voids where the metal shrinks unevenly.

Preheating directly combats the formation of shrinkage cavities and porosity defects. By keeping the cooling slow and steady, the metal can feed into shrinking areas more effectively.

Mitigating Internal Stress

When an alloy cools unevenly or too fast, internal forces build up within the material.

Preheating allows for relaxation during solidification, significantly reducing internal thermal stress. This prevents the ingot from cracking or warping after it is removed from the mold.

Common Pitfalls: The Risks of Rapid Cooling

While preheating adds a step to the process, skipping it introduces severe quality risks that outweigh the time savings.

The Trade-off of Efficiency vs. Quality

If you attempt to cast LAS830 into a cold mold to save time, you dramatically increase the rejection rate. The resulting microstructure will likely be non-uniform, leading to inconsistent mechanical properties across the ingot.

Defect Propagation

Without the thermal buffer of a 250 °C mold, the rapid solidification front can trap defects deep inside the ingot. These internal flaws often remain undetected until machining or failure in service.

Making the Right Choice for Your Goal

To achieve a high-quality LAS830 ingot, you must view the mold temperature as a variable that is just as important as the alloy composition itself.

- If your primary focus is structural integrity: Preheating is non-negotiable to eliminate porosity and shrinkage cavities that weaken the metal.

- If your primary focus is material consistency: Maintain the mold at 250 °C to ensure the cooling rate produces a uniform microstructure throughout the blank.

Mastering the mold temperature is the simplest way to transform a volatile casting process into a reliable manufacturing routine.

Summary Table:

| Factor | Without Preheating (Cold Mold) | With Preheating (250 °C) |

|---|---|---|

| Cooling Rate | Rapid and uncontrolled | Gradual and stable |

| Melt Fluidity | Poor, leads to incomplete filling | High, ensures even distribution |

| Internal Stress | High risk of cracking/warping | Low, allows thermal relaxation |

| Microstructure | Non-uniform and inconsistent | Uniform and refined |

| Common Defects | Shrinkage cavities and porosity | Minimized or eliminated |

Optimize Your Alloy Production with KINTEK

Precise thermal management is the difference between a failed ingot and a high-performance material. KINTEK provides the specialized equipment needed to master complex casting processes for LAS830 and other advanced alloys.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your unique metallurgical needs.

Ready to eliminate casting defects and enhance material consistency? Contact us today to discover how our expert heating solutions can transform your lab’s manufacturing routine.

Visual Guide

References

- Changzhen Jia, Pengcheng Tian. Microstructure and Mechanical Properties of Mg-8Li-3Al-0.3Si Alloy Deformed Through a Combination of Back-Extrusion and Spinning Process. DOI: 10.3390/ma18020417

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why are rotary evaporators or industrial ovens recommended for handling Boron Carbide mixed slurries containing solvents?

- How does temperature control precision affect SC-NMNO crystal morphology? Master Thermal Fields for High-Quality Grains

- Why is MgO used as a hard template for waste PET to carbon conversion? Unlock 3D Porous Structures

- How does a high-precision Vertical Bridgman Furnace facilitate ZnGeP2 growth? Master Single Crystal Production

- What is the technical purpose of drying NaNbO3:Pr3+ precursors at 60 °C? Optimize Your Powder Synthesis

- Why is a high-temperature annealing process in a vacuum oven required for CMSMs? Unlock Membrane Precision

- Why is a vacuum storage environment necessary for solid polymer electrolyte films? Ensure Film Integrity & Data Accuracy

- How does an autoclave assist in modifying bio-carbon with cobalt oxide? Unlock High-Performance Nano-Composites