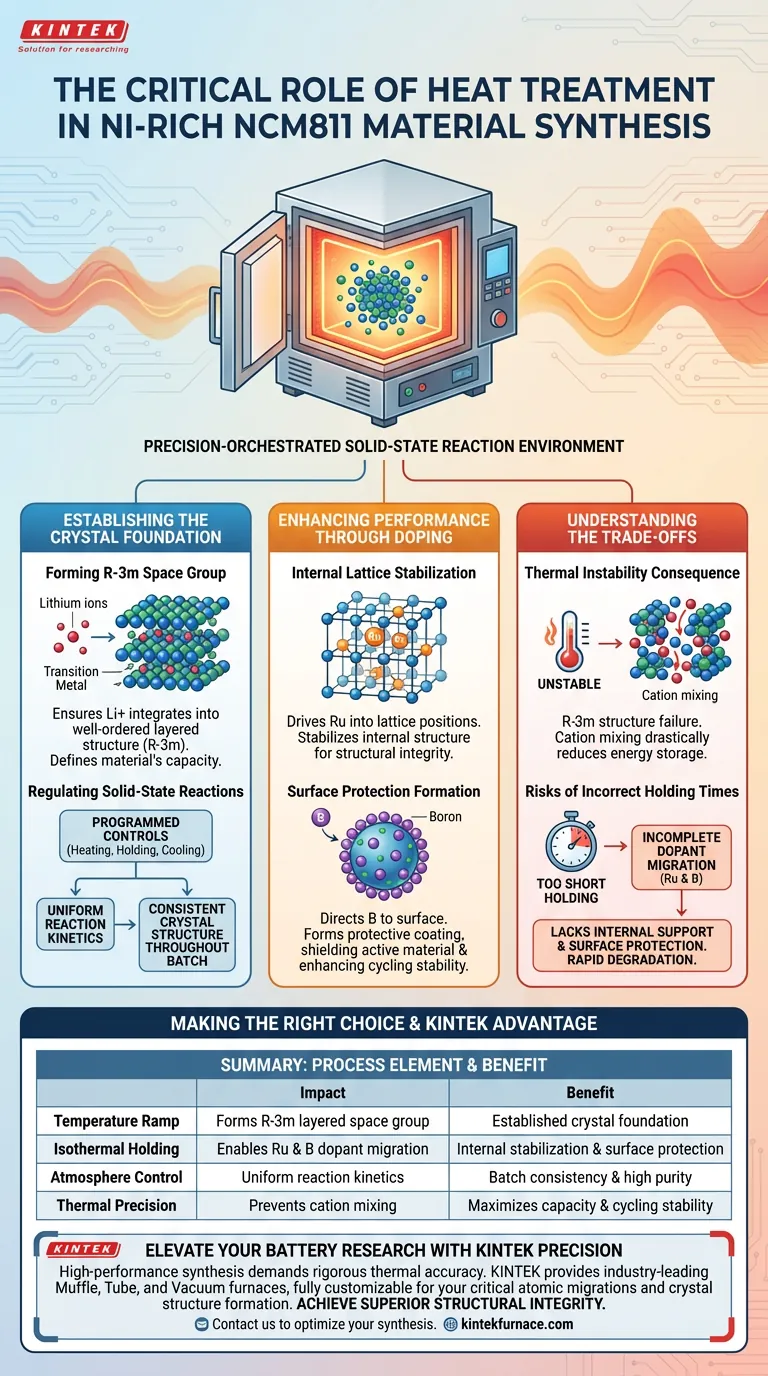

The significance of the heat treatment in high-temperature box furnaces lies in its ability to precisely orchestrate the solid-state reaction environment. These furnaces utilize programmed heating, isothermal holding, and cooling rates to ensure lithium ions successfully integrate into transition metal layers. This process creates the necessary well-ordered layered structure (R-3m space group) while facilitating the critical migration of dopants, directly determining the material's capacity and cycling stability.

High-performance NCM811 cathodes cannot be formed through simple heating; they require a rigorously controlled thermal program. The furnace's ability to drive specific atomic migrations—placing dopants into the lattice or onto the surface—is the defining factor in achieving structural integrity and long-term battery reliability.

Establishing the Crystal Foundation

Forming the R-3m Space Group

The primary objective of the heat treatment is to enable lithium ions to permeate the transition metal layers effectively.

This specific atomic arrangement forms a well-ordered layered structure, scientifically known as the R-3m space group. Without the precise temperature control provided by the box furnace, this ordering is disrupted, preventing the material from functioning efficiently as a battery cathode.

Regulating Solid-State Reactions

High-temperature box furnaces provide the environment necessary for solid-state reactions to occur uniformly.

By utilizing programmed controls, the furnace manages the kinetics of the reaction. This ensures that the formation of the crystal structure is consistent throughout the entire batch of material, rather than just on the surface.

Enhancing Performance Through Doping

Internal Lattice Stabilization

The thermal energy provided by the furnace drives dopants like Ruthenium (Ru) into specific crystal lattice positions.

This migration is not spontaneous at lower temperatures; it requires sustained, precise heat. Successfully integrating Ru into the lattice is crucial for stabilizing the internal structure of the material, which supports structural integrity during repeated charge cycles.

Surface Protection Formation

Simultaneously, the heat treatment directs elements like Boron (B) to migrate to the surface of the material.

This process forms a protective coating on the NCM811 particles. This coating is essential for shielding the active material from side reactions with the electrolyte, thereby significantly enhancing cycling stability.

Understanding the Trade-offs

The Consequence of Thermal Instability

While high heat is necessary, the margin for error is slim.

If the furnace fails to maintain precise temperature uniformity, the R-3m layered structure may not form correctly. This often leads to cation mixing, where transition metals block the pathways intended for lithium, drastically reducing the battery's energy storage capability.

Risks of Incorrect Holding Times

The duration of the isothermal holding time is just as critical as the maximum temperature.

If the holding time is too short, the migration of dopants like Ru and B will be incomplete. This results in a material that lacks both internal structural support and external surface protection, leading to rapid degradation during use.

Making the Right Choice for Your Synthesis

To maximize the performance of Ni-Rich NCM811 materials, you must align your thermal profile with your specific chemical goals.

- If your primary focus is Crystal Quality: Prioritize precise temperature ramp rates and stability to ensure the complete formation of the R-3m layered structure.

- If your primary focus is Cycling Stability: Ensure sufficient isothermal holding times to allow full migration of Ruthenium into the lattice and Boron to the surface.

The precision of your heat treatment directly dictates the electrochemical limits and lifespan of your final cathode material.

Summary Table:

| Process Element | Impact on NCM811 Material | Primary Benefit |

|---|---|---|

| Temperature Ramp | Forms the R-3m layered space group | Established crystal foundation |

| Isothermal Holding | Enables Ru & B dopant migration | Internal stabilization & surface protection |

| Atmosphere Control | Uniform solid-state reaction kinetics | Batch consistency & high purity |

| Thermal Precision | Prevents cation mixing/disorder | Maximizes capacity & cycling stability |

Elevate Your Battery Research with KINTEK Precision

High-performance NCM811 synthesis demands the rigorous thermal accuracy found only in specialized laboratory equipment. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces specifically engineered to facilitate critical atomic migrations and crystal structure formation.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet the unique ramp rates and isothermal holding requirements of your next-generation cathode materials.

Ready to achieve superior structural integrity? Contact us today to discuss how KINTEK's high-temp solutions can optimize your synthesis process.

Visual Guide

References

- Liang‐Yin Kuo, Payam Kaghazchi. Doping‐Induced Surface and Grain Boundary Effects in Ni‐Rich Layered Cathode Materials. DOI: 10.1002/smll.202307678

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- How is an industrial-grade ashing furnace utilized in 3D-printed bioactive glass? Master Debinding & Sintering

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What role does a Muffle Furnace play in 1100°C oxidation experiments? Precision Thermal Control for Coatings