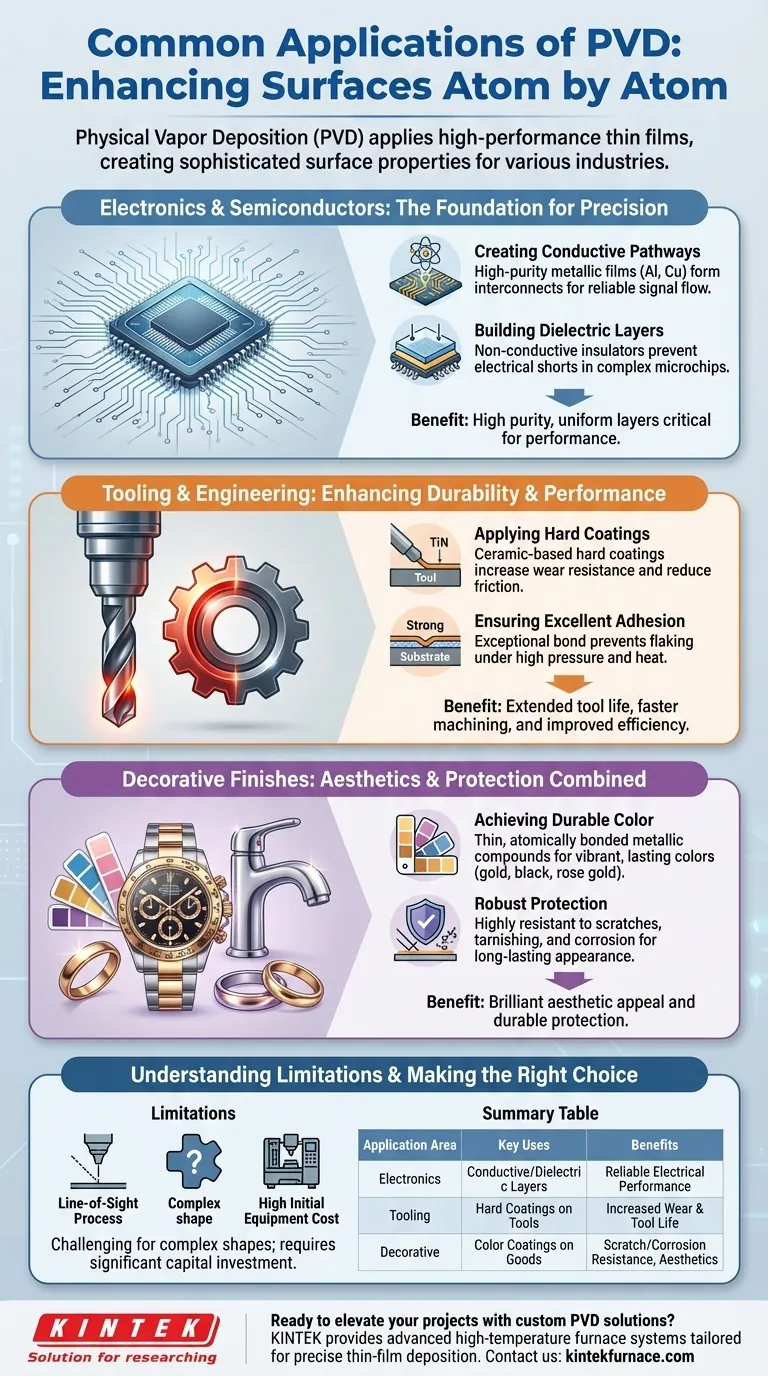

In short, Physical Vapor Deposition (PVD) is a sophisticated vacuum coating process used to apply high-performance thin films onto a wide range of parts. Its most common applications are found in the electronics industry for creating semiconductors, the tooling industry for hardening cutting tools, and for producing durable decorative finishes on consumer goods like watches and jewelry.

PVD is not just a coating; it is a method for fundamentally enhancing a material's surface properties. Whether the goal is electrical conductivity, extreme hardness, or a brilliant, lasting finish, PVD delivers these properties by depositing a highly pure and durable thin film atom by atom.

The Foundation: PVD in Electronics and Semiconductors

The precision required for modern electronics makes PVD an essential manufacturing process. Its ability to create exceptionally pure and uniform layers is critical for performance.

Creating Conductive Pathways

In semiconductor fabrication, PVD is used to deposit thin layers of metals like aluminum or copper. These layers form the microscopic circuits, or interconnects, that allow electricity to flow through the chip.

The process ensures these metallic films are free of impurities that could otherwise disrupt electrical performance.

Building Dielectric Layers

PVD is also used to deposit non-conductive, or dielectric, films. These materials act as insulators, preventing electrical signals from "shorting out" between different layers of a complex microchip.

Enhancing Durability: PVD in Tooling and Engineering

In industrial settings, the primary goal of PVD is to extend the life and improve the performance of tools that cut, drill, or form other materials.

Applying Hard Coatings

PVD is used to apply ceramic-based hard coatings, such as Titanium Nitride (TiN), onto cutting tools, drill bits, and injection molds. These coatings are often only a few microns thick but are extremely hard and possess a low coefficient of friction.

This added hardness dramatically increases the tool's resistance to wear, while the improved lubricity reduces heat buildup, allowing for faster and more efficient machining.

Ensuring Excellent Adhesion

A key advantage of PVD is the exceptional bond it creates between the coating and the tool's surface (the substrate). This strong adhesion ensures the coating does not flake or chip off, even under the intense pressure and high temperatures of industrial use.

Aesthetics and Protection: PVD in Decorative Finishes

PVD offers a unique combination of brilliant aesthetics and robust protection, making it a preferred choice for premium consumer goods.

Achieving Durable Color

For products like watches, faucets, and jewelry, PVD can deposit a thin layer of metallic compounds that produce a wide range of colors—from gold and black to rose gold and blue.

Unlike painting or plating, this PVD layer is not just on the surface; it's atomically bonded to it. This provides a finish that is highly resistant to scratches, tarnishing, and corrosion, maintaining its appearance for years.

Understanding the Limitations of PVD

While powerful, PVD is not the perfect solution for every scenario. Understanding its trade-offs is key to applying it correctly.

It Is a Line-of-Sight Process

The material being deposited travels in a straight line from the source to the target part. This can make it challenging to achieve a perfectly uniform coating on components with highly complex shapes, deep recesses, or internal channels.

High Initial Equipment Cost

PVD systems require a significant capital investment. The machinery involves creating a high-vacuum environment and using sophisticated power sources, making it more expensive upfront than traditional coating methods like electroplating.

Making the Right Choice for Your Goal

PVD's versatility means its application depends entirely on the desired outcome. You must select it based on the specific surface property you need to enhance.

- If your primary focus is high-purity electrical performance: PVD is the standard for creating the clean, uniform conductive and dielectric films required for semiconductors.

- If your primary focus is maximum hardness and tool life: PVD hard coatings provide unmatched wear resistance and lubricity for cutting and forming tools.

- If your primary focus is a durable, premium aesthetic: PVD delivers brilliant decorative finishes that are far more resistant to scratches and corrosion than traditional methods.

Ultimately, PVD is the definitive technology for engineering a surface to perform a specific function with exceptional reliability.

Summary Table:

| Application Area | Key Uses | Benefits |

|---|---|---|

| Electronics & Semiconductors | Deposition of conductive and dielectric layers | High purity, uniform films for reliable electrical performance |

| Tooling & Engineering | Hard coatings (e.g., TiN) on cutting tools and molds | Increased wear resistance, reduced friction, extended tool life |

| Decorative Finishes | Color coatings on watches, jewelry, and consumer goods | Scratch and corrosion resistance, lasting aesthetic appeal |

Ready to elevate your projects with custom PVD solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD Systems, tailored for precise thin-film deposition. Whether you're in electronics, tooling, or decorative industries, our deep customization capabilities ensure your unique requirements are met. Contact us today to discuss how we can enhance your performance and durability!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition