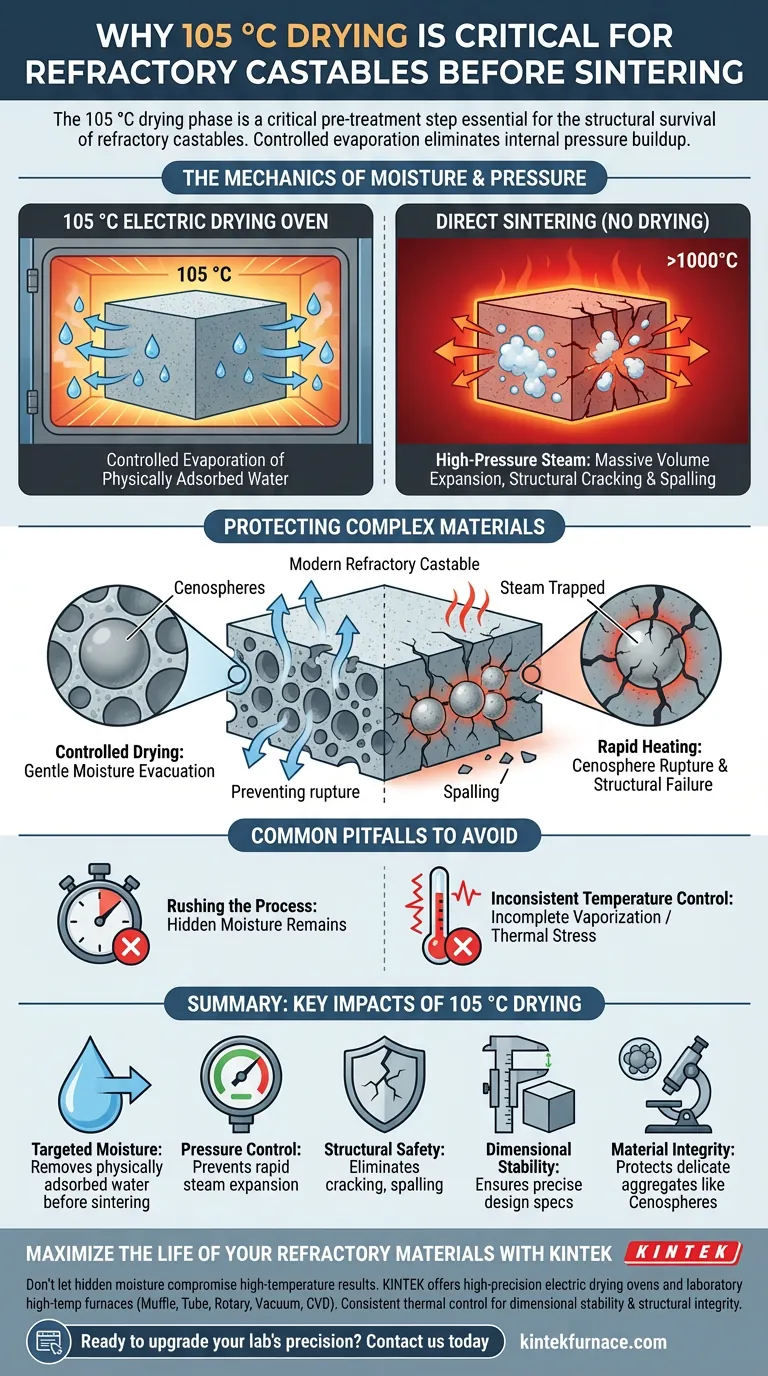

The 105 °C drying phase is a critical pre-treatment step essential for the structural survival of refractory castables. By holding the material at this specific constant temperature in an electric drying oven, you effectively remove physically adsorbed water before the material is subjected to the extreme heat of formal sintering. This controlled evaporation is the primary defense against internal pressure buildup that destroys material integrity.

Sintering wet refractory materials creates dangerous internal steam pressure. The 105 °C drying process eliminates this moisture in a controlled environment, preventing structural cracking and ensuring the dimensional stability of components containing lightweight aggregates.

The Mechanics of Moisture and Pressure

Targeting Physically Adsorbed Water

Refractory castables naturally retain moisture within their internal structure. This is known as physically adsorbed water.

Before the chemical changes of sintering can occur, this physical water must be evacuated. An electric drying oven set to 105 °C provides the precise thermal environment to vaporize this water without initiating premature chemical reactions.

The Threat of High-Pressure Steam

If a castable containing moisture is immediately subjected to high sintering temperatures, the water does not simply evaporate; it flashes into steam.

This phase change results in a massive volume expansion. When this occurs deep inside the material, it generates high-pressure steam that exerts tremendous outward force on the material's internal structure.

Protecting Complex Materials

Managing Cenospheres and Porosity

Modern refractory castables often utilize lightweight aggregates, such as Cenospheres.

These materials are beneficial for insulation but can create complex pore structures that trap water. Controlled drying is vital to gently coax moisture out of these lightweight components without rupturing their delicate walls.

Preventing Structural Failure

The rapid expansion of steam is the leading cause of structural cracking and spalling (surface peeling) during the sintering phase.

By ensuring the material is dry prior to high-temperature exposure, you eliminate the internal stress drivers that cause these catastrophic failures.

Ensuring Dimensional Stability

Beyond preventing cracks, moisture removal is key to maintaining the correct shape and size of the component.

A gradual 105 °C drying process ensures that the refractory component maintains its dimensional stability, resulting in a final product that fits design specifications accurately.

Common Pitfalls to Avoid

The Risk of Rushing the Process

It is a mistake to view the 105 °C phase as a mere formality that can be shortened.

If the dwell time in the electric oven is insufficient, pockets of moisture will remain deep within the core of the castable. These hidden pockets will still vaporize explosively during sintering, regardless of how dry the surface appears.

Inconsistent Temperature Control

The use of an electric drying oven is significant because it maintains a constant temperature.

Fluctuating temperatures below 100 °C may fail to fully vaporize the water, while uncontrolled spikes could induce thermal stress before the material is ready. Precision at this stage is mandatory for consistent results.

Making the Right Choice for Your Project

To maximize the lifespan and performance of your refractory castables, apply the drying process according to your specific material composition:

- If your primary focus is Structural Integrity: Ensure the drying duration is long enough to remove all physically adsorbed water to prevent spalling.

- If your primary focus is Material Composition: Pay extra attention to drying times when using porous aggregates like Cenospheres, as they require careful moisture evacuation.

A disciplined 105 °C drying cycle is the low-temperature investment that guarantees high-temperature success.

Summary Table:

| Feature | Impact on Refractory Castables |

|---|---|

| Targeted Moisture | Removes physically adsorbed water before sintering |

| Pressure Control | Prevents rapid steam expansion and internal structural force |

| Structural Safety | Eliminates the risk of cracking, spalling, and surface peeling |

| Dimensional Stability | Ensures final components maintain precise design specifications |

| Material Integrity | Protects delicate aggregates like Cenospheres from rupturing |

Maximize the Life of Your Refractory Materials with KINTEK

Don't let hidden moisture compromise your high-temperature results. Backed by expert R&D and manufacturing, KINTEK offers high-precision electric drying ovens and a full suite of laboratory high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our equipment provides the consistent thermal control needed to ensure the dimensional stability and structural integrity of your unique materials.

Ready to upgrade your lab's precision? Contact us today to discover our customizable solutions tailored to your specific sintering and drying needs!

Visual Guide

References

- Effect of Prewetting Cenospheres on Hydration Kinetics, Microstructure, and Mechanical Properties of Refractory Castables. DOI: 10.3390/cryst15010068

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the function of a laboratory drying oven in processing NdFeB waste? Ensure Purity in Rare Earth Recovery

- What is the significance of using a high-precision gas mass flow controller for hydrogen flow? | Master Uniform Thermal Reduction

- What is the primary role of high-purity hydrogen in heat treatment? Achieve Superior Metallic Coating Protection

- What is the technical purpose of drying NaNbO3:Pr3+ precursors at 60 °C? Optimize Your Powder Synthesis

- How does the use of carbon dioxide and a flow meter impact the physical activation of biochar? Master Pore Development

- What are the advantages of using the tin flux method? Achieve High-Quality Eu5.08-xSrxAl3Sb6 Single Crystal Growth

- What additional techniques are used in activated sintering? Boost Efficiency with Advanced Chemical Methods

- Why is high-precision temperature control of the heating base critical during FTO spray pyrolysis? Maximize Film Quality