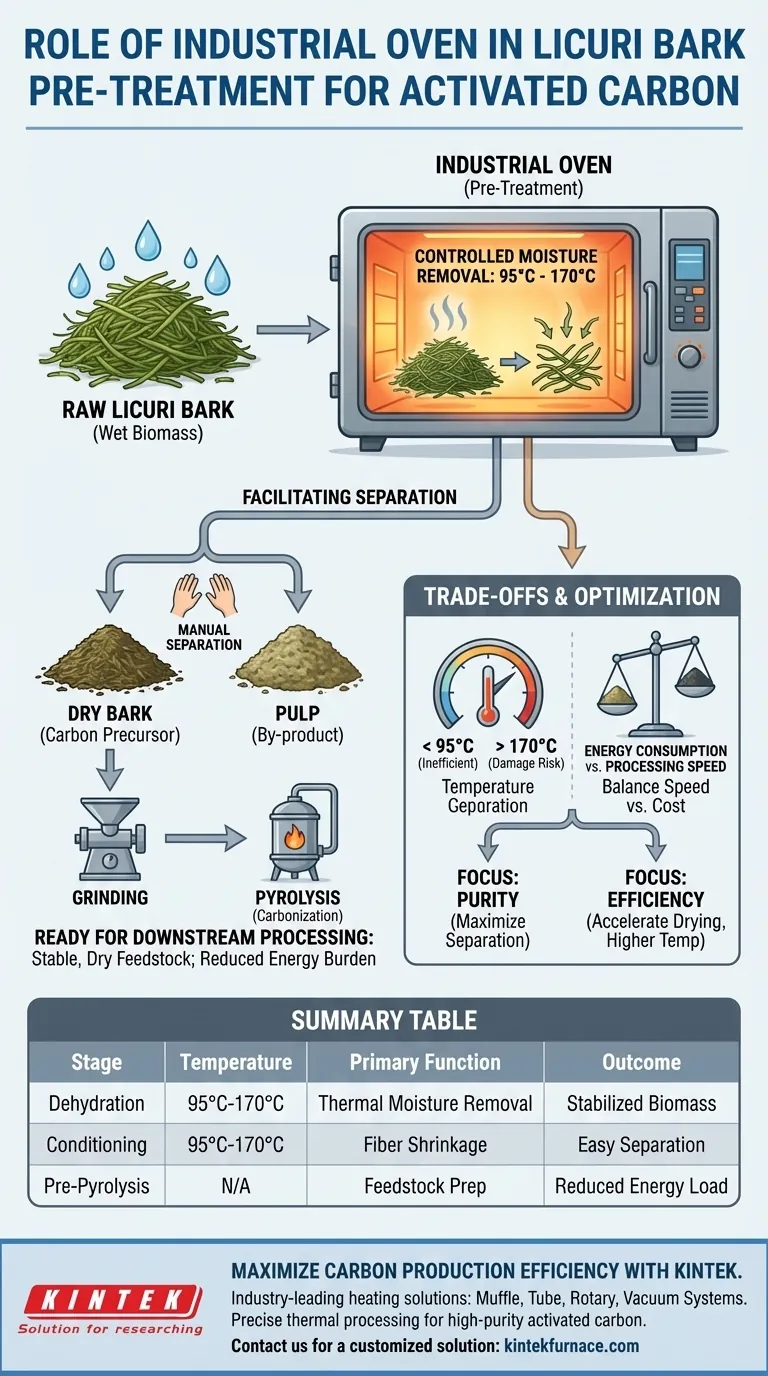

In the production of activated carbon from Licuri bark, the industrial oven serves as a critical dehydration mechanism that prepares the raw biomass for processing. By applying controlled heat within a specific range of 95°C to 170°C, the oven removes excess moisture to stabilize the material and physically facilitate the separation of the bark from the pulp.

The industrial oven functions as a mechanical enabler rather than just a heating element. By dehydrating the Licuri at precise temperatures, it loosens the biomass structure to allow for efficient manual separation, ensuring a pure, dry feedstock is ready for grinding and pyrolysis.

The Mechanics of Pre-Treatment Drying

Controlled Moisture Removal

The primary function of the industrial oven is the thermal elimination of water content from the raw Licuri bark.

To achieve this without degrading the biomass, the process requires a strict temperature window between 95°C and 170°C.

Operating within this range ensures that moisture is evaporated effectively without initiating premature combustion or chemical breakdown of the carbon precursor.

Facilitating Material Separation

Beyond simple drying, the oven plays a vital role in the physical preparation of the raw material.

The drying process shrinks the plant fibers, which loosens the bond between the outer bark and the inner pulp.

This thermal conditioning is essential because it allows operators to perform manual separation of the bark from the pulp with much greater efficiency.

Preparation for Downstream Processing

Establishing Material Stability

Wet biomass is unpredictable and difficult to process mechanically.

The industrial oven converts the raw Licuri into a dry, stable material foundation.

This stability is a prerequisite for the subsequent stages, specifically enabling the material to be ground down effectively without clogging machinery due to moisture.

Readiness for Pyrolysis

The ultimate goal of pre-treatment is to prepare the feedstock for carbonization (pyrolysis).

By removing moisture beforehand, the oven reduces the energy burden on the pyrolysis reactor.

It ensures that the material entering the high-heat stage is consistent, allowing for a more controlled and efficient conversion into activated carbon.

Understanding the Trade-offs

Temperature Sensitivity

While heat is necessary, precise control is paramount.

If the temperature drops below 95°C, the drying process becomes inefficient, potentially failing to loosen the bark from the pulp effectively.

Conversely, exceeding 170°C risks damaging the organic structure of the bark before the actual carbonization stage begins, which could compromise the quality of the final activated carbon.

Energy Consumption vs. Processing Speed

Industrial drying is an energy-intensive step in the manufacturing lifecycle.

Higher temperatures (closer to 170°C) may speed up the drying process but increase energy costs significantly.

Operators must balance the speed of moisture removal against the operational costs of running the ovens at the upper limits of the recommended range.

Optimizing the Pre-Treatment Phase

To maximize the quality of your Licuri-based activated carbon, you must tailor the oven settings to your specific processing constraints.

- If your primary focus is material purity: Maintain temperatures that maximize the physical separation of bark and pulp, ensuring no pulp contaminates the carbon feedstock.

- If your primary focus is process efficiency: Operate closer to the 170°C upper limit to accelerate drying times, provided your energy budget allows for it.

By strictly controlling the drying environment, you ensure a consistent, high-quality precursor that is essential for effective activation.

Summary Table:

| Stage | Temperature Range | Primary Function | Outcome |

|---|---|---|---|

| Dehydration | 95°C - 170°C | Thermal moisture removal | Stabilized, dry biomass |

| Conditioning | 95°C - 170°C | Fibrous structure shrinkage | Easy separation of bark from pulp |

| Pre-Pyrolysis | N/A | Feedstock preparation | Reduced energy load for carbonization |

Maximize Your Carbon Production Efficiency with KINTEK

Quality activated carbon begins with precise thermal pre-treatment. KINTEK provides industry-leading heating solutions, including high-performance Muffle, Tube, Rotary, and Vacuum systems, engineered to maintain the strict temperature windows required for biomass dehydration.

Whether you are processing Licuri bark or advanced organic precursors, our customizable laboratory and industrial furnaces ensure uniform heating and consistent material stability. Backed by expert R&D and manufacturing, we help you transition seamlessly from raw biomass to high-purity activated carbon.

Ready to optimize your thermal processing? Contact KINTEK today for a customized solution

Visual Guide

References

- Charlotte Santana Velame, Ary Rocha Bezerra. Application of Activated Carbon Produced from Licuri Bark (Syagrus coronata) in Water Filtration. DOI: 10.34178/jbth.v8i2.476

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the heating system of a program-controlled atmosphere furnace work? Unlock Precision Heating for Your Lab

- What is the primary function of a tube atmosphere furnace? Mastering Ti3AlC2 MAX Phase Synthesis

- What is the purpose of the 1000 °C pre-annealing treatment for copper foil? Optimize acm-BN Growth Success

- What is the role of a chemical reactor with thermogravimetric measurement in nitriding? Master AISI 1085 Kinetics

- What roles do inert gases like argon or helium play when processing molten stainless steel? Enhance Alloy Composition

- What is the core difference between box and atmosphere furnaces? Choose the Right Equipment for Your Lab

- What is the primary purpose of introducing high-purity nitrogen during furnace cooling? Ensure Data Integrity

- Why is an XHV equivalent protective atmosphere required for heating uncoated steel? Achieve Scale-Free Surface Purity