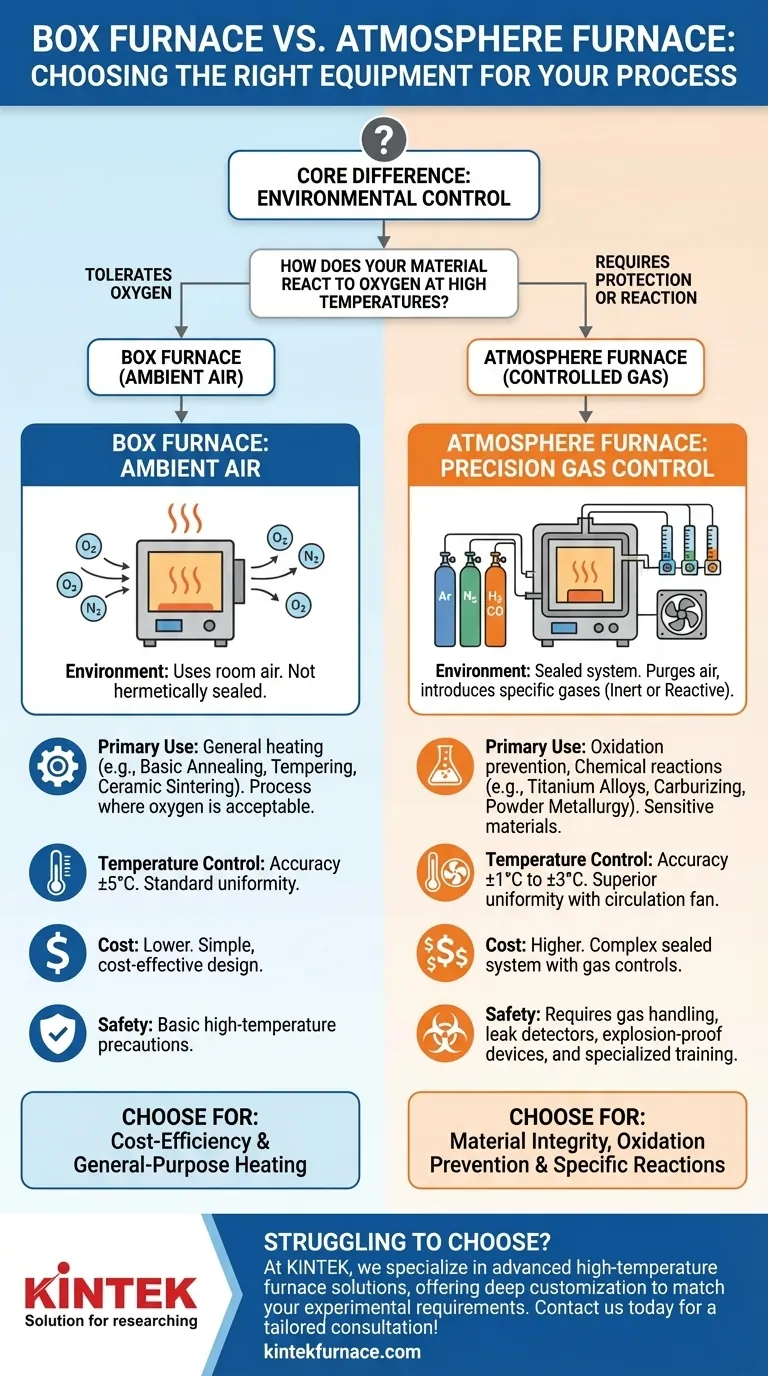

At their core, the difference between a box furnace and an atmosphere furnace is one of environmental control. A box furnace operates in the natural air surrounding it, making it a simple and robust tool for general heating. An atmosphere furnace, however, creates a tightly sealed environment where specific gases can be introduced to prevent oxidation or enable precise chemical reactions on the material's surface.

Your choice hinges on a single, critical question: How does your material react to oxygen and other elements in the air at high temperatures? The answer dictates whether you need the simple utility of a box furnace or the precise control of an atmosphere furnace.

The Defining Factor: Your Process Atmosphere

The most fundamental distinction between these furnaces is the environment in which your material is heated. This single factor drives all other differences in design, cost, and application.

The Box Furnace: Operating in Ambient Air

A box furnace, often called a muffle furnace, uses the air in the room as its processing atmosphere. Its chamber is enclosed but not hermetically sealed.

This design is ideal for processes where exposure to oxygen and nitrogen is acceptable or even required. This includes many common applications like basic metal annealing, tempering, and the sintering of certain ceramics.

The Atmosphere Furnace: Precision Gas Control

An atmosphere furnace is engineered to be a sealed system. It allows you to first purge the ambient air and then introduce a specific, controlled gas or gas mixture.

This capability is essential for two reasons: protection and reaction. It protects sensitive materials like titanium alloys or metal powders from oxidizing at high temperatures. It also enables reactive processes, such as introducing carbon-rich gas for carburization, that alter the material's surface chemistry.

Comparing Core Design and Cost Implications

The need for atmospheric control directly impacts the furnace's construction, complexity, and ultimately, its price.

Structural Simplicity and Cost-Effectiveness

The box furnace features a relatively simple design. The door has a basic seal to retain heat, but it is not gas-tight. This straightforward construction makes them significantly more economical to manufacture and purchase.

Sealed Integrity and System Complexity

An atmosphere furnace requires a highly engineered, sealed chamber to prevent gas leaks. It is equipped with dedicated gas inlet and outlet ports, flow meters, and pressure control systems to maintain a stable, positive-pressure environment. This complexity results in a higher manufacturing and acquisition cost.

Temperature Precision and Uniformity

While both are effective, their control levels differ. A box furnace typically offers temperature control accuracy within ±5°C.

An atmosphere furnace often delivers higher accuracy, around ±1°C to ±3°C, and frequently includes a gas circulation fan. This fan ensures superior temperature uniformity throughout the chamber, which is critical for consistent results in sensitive processes.

Understanding the Trade-offs: Safety and Operation

The capabilities of each furnace type come with distinct operational and safety considerations. These trade-offs are crucial for planning your facility and personnel requirements.

The Box Furnace: Straightforward and Accessible

Operating a box furnace is relatively simple. The primary safety concerns revolve around high-temperature protection for personnel. They are well-suited for general laboratory or industrial environments without needing specialized infrastructure beyond an appropriate power supply.

The Atmosphere Furnace: A Higher Operational Burden

The use of controlled gases introduces significant safety responsibilities. Many process gases, such as hydrogen, are flammable or explosive.

This necessitates robust safety protocols, including gas leak detectors, explosion-proof devices, and proper ventilation. Operators must be professionally trained to handle pressurized gases and manage the complex control systems safely, representing a higher operational and training investment.

Making the Right Choice for Your Goal

Your application's specific requirements will clearly point to the correct furnace. Evaluate your primary objective to make a confident decision.

- If your primary focus is cost-efficiency and general-purpose heating: A box furnace is the ideal choice for processes like basic tempering or ceramic firing where air exposure is not a concern.

- If your primary focus is material integrity and preventing oxidation: An atmosphere furnace is non-negotiable for processing sensitive materials like titanium alloys, semiconductor components, or high-purity metal powders.

- If your primary focus is enabling specific chemical reactions: You need an atmosphere furnace to introduce reactive gases for processes like carburizing, nitriding, or creating a reducing environment for powder metallurgy.

- If your primary focus is maximum temperature uniformity and precision: The gas circulation and advanced controls of an atmosphere furnace provide the superior consistency required for high-value materials and research applications.

Ultimately, selecting the right furnace comes down to a clear understanding of your material's chemistry and your process's atmospheric requirements.

Summary Table:

| Feature | Box Furnace | Atmosphere Furnace |

|---|---|---|

| Atmosphere | Ambient air (oxygen/nitrogen) | Controlled gas (e.g., inert or reactive) |

| Primary Use | General heating (e.g., annealing, tempering) | Oxidation prevention, chemical reactions |

| Temperature Control | ±5°C accuracy | ±1°C to ±3°C accuracy with uniformity |

| Cost | Lower (simple design) | Higher (sealed system, gas controls) |

| Safety | Basic high-temperature precautions | Requires gas handling, detectors, and training |

Struggling to choose the right furnace for your lab's unique needs? At KINTEK, we specialize in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to precisely match your experimental requirements—whether you need cost-effective general heating or precise atmospheric control. Let our experts help you optimize your processes and enhance efficiency. Contact us today for a tailored consultation!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process