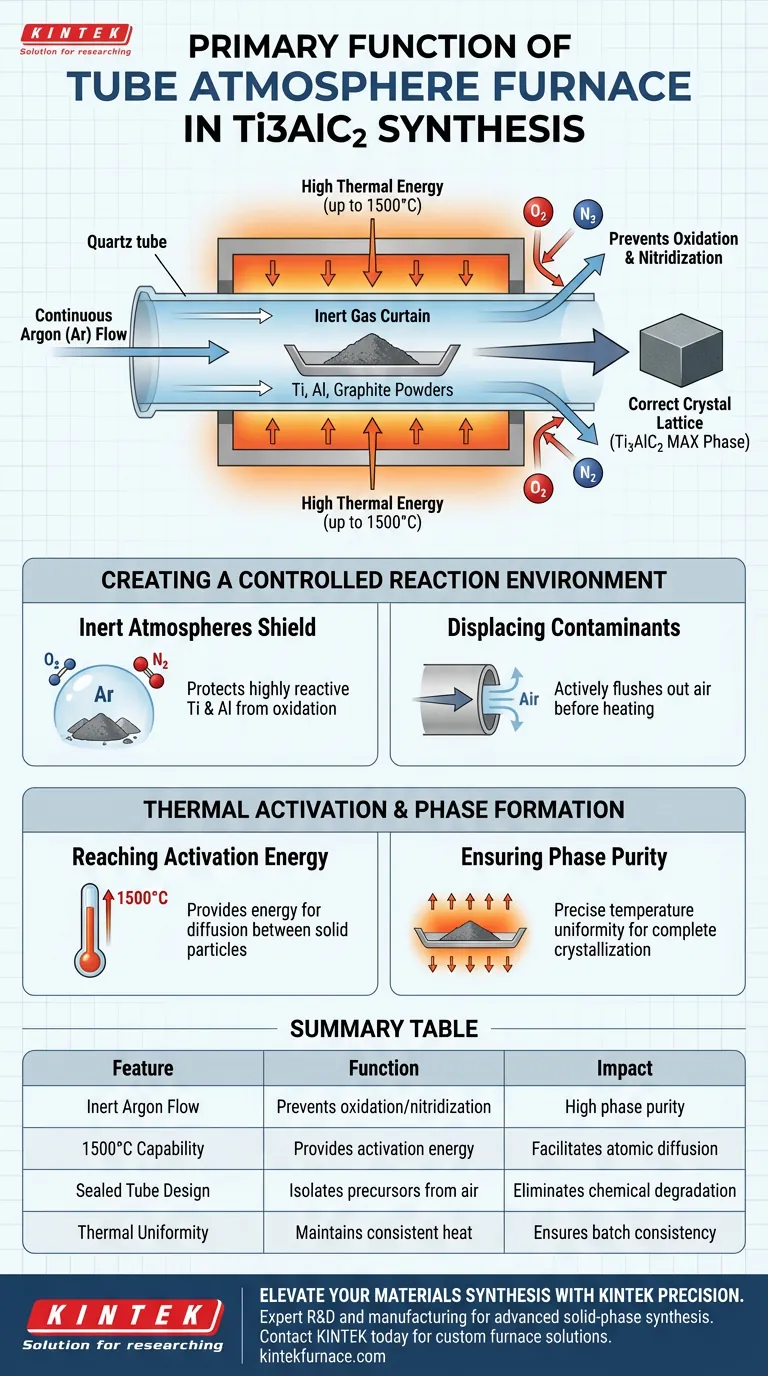

The primary function of a tube atmosphere furnace in the synthesis of Ti3AlC2 MAX phase materials is to generate the high thermal energy required for reaction while simultaneously preventing chemical degradation. It heats titanium, aluminum, and graphite powders to temperatures up to 1500°C while maintaining a continuous flow of inert Argon (Ar) gas. This isolates the reactive precursors from oxygen, ensuring the synthesis yields the correct crystal lattice rather than unwanted oxides.

Core Takeaway Reliable solid-phase synthesis requires balancing extreme heat with total chemical isolation. The tube atmosphere furnace acts as a controlled reactor that supplies the necessary activation energy for crystal formation while utilizing an inert gas curtain to strictly forbid the oxidation of highly reactive metal powders.

Creating a Controlled Reaction Environment

The Necessity of Inert Atmospheres

The most critical role of the furnace is shielding raw materials. Titanium and aluminum powders are highly reactive metals.

If exposed to oxygen or nitrogen at elevated temperatures, these materials will rapidly oxidize or nitridize. The tube furnace prevents this by creating a sealed environment purged with high-purity Argon.

Displacing Contaminants

Before heating begins, the furnace allows for the displacement of air within the chamber.

By maintaining a continuous flow of Argon, the system actively flushes out potential contaminants. This ensures that the environment remains chemically inert throughout the entire heating and cooling cycle.

Thermal Activation and Phase Formation

Reaching Activation Energy

Solid-phase synthesis requires significant thermal energy to initiate the reaction between powders.

The tube furnace provides the capability to reach temperatures up to 1500°C (often operating around 1380°C for this specific material). This high heat provides the activation energy needed for the diffusion of atoms between solid particles.

Ensuring Phase Purity

Beyond simply reaching high temperatures, the quality of the heat matters.

A high-quality tube furnace offers precise temperature uniformity. This ensures that the entire batch of material experiences the same thermal conditions, which is critical for achieving complete crystallization and high phase purity in the final Ti3AlC2 product.

Understanding the Trade-offs

Sensitivity to Gas Purity

While the furnace design is robust, the system is entirely dependent on the quality of the input gas.

Even a minor leak in the tube seals or low-purity Argon can introduce enough oxygen to ruin the synthesis. The furnace cannot "clean" impure gas; it can only maintain the atmosphere provided to it.

Batch Processing Limitations

Standard tube furnaces are typically designed for batch processing.

While excellent for ensuring uniformity and control in laboratory or pilot settings, they may limit throughput compared to continuous flow designs (like rotary furnaces) used for loose powder processing.

Making the Right Choice for Your Goal

To maximize the quality of your Ti3AlC2 synthesis, consider how you operate the equipment based on your specific objectives:

- If your primary focus is phase purity: Prioritize a furnace with a long constant temperature zone to ensure exceptional thermal uniformity across the entire sample boat.

- If your primary focus is preventing oxidation: Invest heavily in high-grade sealing flanges and ultra-high purity Argon gas sources to complement the furnace's isolation capabilities.

The tube atmosphere furnace is not just a heater; it is the primary vessel for protecting the delicate stoichiometry of your material against the environment.

Summary Table:

| Feature | Function in Ti3AlC2 Synthesis | Impact on Final Product |

|---|---|---|

| Inert Argon Flow | Prevents oxidation and nitridization of Ti/Al | Ensures high phase purity and lattice integrity |

| 1500°C Capability | Provides necessary activation energy | Facilitates atomic diffusion between solid particles |

| Sealed Tube Design | Isolates reactive precursors from air | Eliminates chemical degradation and contaminants |

| Thermal Uniformity | Maintains consistent heat across the sample | Prevents mixed phases and ensures batch consistency |

Elevate Your Materials Synthesis with KINTEK Precision

Achieving the perfect Ti3AlC2 MAX phase requires more than just heat; it demands absolute atmospheric control and thermal precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for advanced solid-phase synthesis.

Whether you need customizable lab high-temp furnaces or industrial-scale solutions, our equipment is designed to protect your reactive precursors and ensure crystalline purity.

Ready to optimize your research? Contact KINTEK today to find your custom furnace solution.

Visual Guide

References

- Oyku Cetin, Hüsnü Emrah Ünalan. MXene‐Deposited Melamine Foam‐Based Iontronic Pressure Sensors for Wearable Electronics and Smart Numpads. DOI: 10.1002/smll.202403202

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What gases are introduced into the box type annealing atmosphere furnace? Optimize Your Heat Treatment Process

- What role does an atmosphere furnace play in industrial-scale production? Unlock Precision in High-Temperature Processing

- What level of temperature stability can be achieved with an experimental box type atmosphere furnace? Achieve ±1°C Precision for Reliable Results

- What core process conditions does a high-temperature tube atmosphere furnace provide for BN-C? Expert Control Tips

- Why is argon gas used for 800HT alloy experiments? Protect Material Integrity with Inert Atmosphere Control

- Why is continuous argon flow essential for biochar pyrolysis? Unlock High-Yield, High-Purity Results

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is the effect of post-deposition annealing (PDA) on fluoride thin films? Optimize 2D Transistor Performance