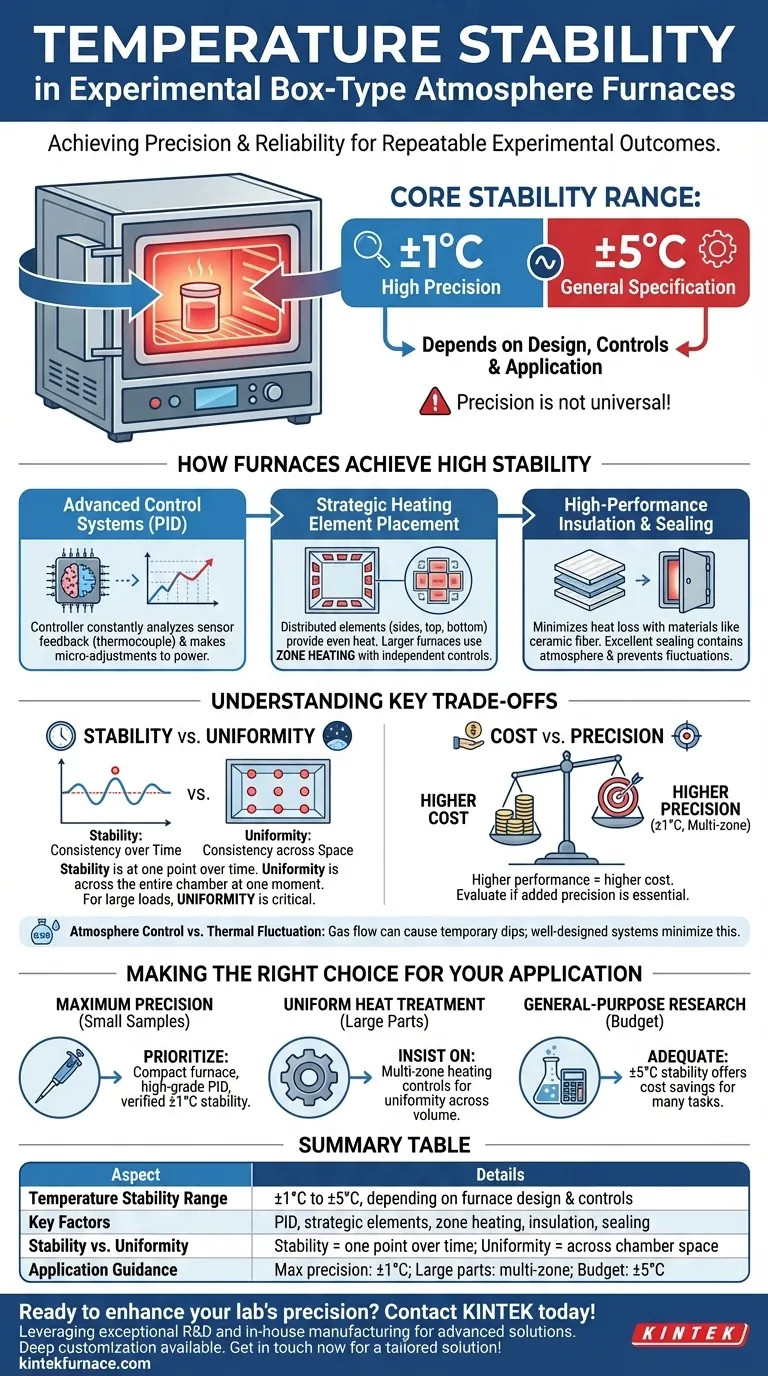

For repeatable experimental outcomes, a high-quality experimental box-type atmosphere furnace can achieve exceptional temperature stability, with advanced models maintaining variations as low as ±1°C. This level of precision is not universal, however, with general specifications ranging from ±1°C to ±5°C depending on the furnace's design, control system, and intended application.

The key takeaway is that while a furnace's technical specification might promise ±1°C stability, true experimental reliability depends on understanding how that stability is achieved and ensuring it translates to temperature uniformity across the entire working chamber.

How Furnaces Achieve High Temperature Stability

Achieving and maintaining a precise temperature in a high-heat environment is a complex engineering challenge. It relies on the seamless integration of several key systems working in concert.

The Role of Advanced Control Systems

The "brain" of the furnace is its temperature control system, typically a PID (Proportional-Integral-Derivative) controller. This controller constantly analyzes feedback from a thermocouple sensor inside the chamber and makes micro-adjustments to the power sent to the heating elements to counteract any temperature drift.

Strategic Heating Element Placement

To prevent hot and cold spots, heating elements are strategically distributed within the furnace. In many models, they are placed on the sides, top, and bottom to provide even radiant and convective heat.

For larger furnaces, a more advanced technique called zone heating is used. This divides the chamber into multiple independent heating zones, each with its own controller and sensor, ensuring the entire volume remains at the target temperature.

High-Performance Insulation and Sealing

Maintaining stability is impossible without first-rate heat containment. Modern furnaces use advanced insulation materials, such as ceramic fiber, to minimize heat loss and isolate the chamber from fluctuations in ambient room temperature.

Furthermore, the furnace's primary function of atmosphere control demands excellent sealing performance. A tightly sealed chamber not only contains the controlled atmosphere (e.g., inert gas) but also prevents heat from escaping, which is critical for thermal stability.

Understanding the Key Trade-offs

The advertised stability figure is an important metric, but it doesn't tell the whole story. You must consider the practical realities and potential trade-offs.

Stability vs. Uniformity

A furnace can have a stability of ±1°C at the thermocouple's location but have a different temperature in a far corner of the chamber. Temperature stability refers to consistency over time at a single point, while temperature uniformity refers to consistency across the entire space at a single moment. For large or sensitive workloads, uniformity is often the more critical metric.

Cost vs. Precision

As with any specialized equipment, higher performance comes at a higher cost. A furnace with ±1°C stability, multi-zone heating, and sophisticated controls will be significantly more expensive than a basic model rated for ±5°C. You must evaluate whether the added precision is essential for your application.

Atmosphere Control vs. Thermal Fluctuation

The very act of managing the internal atmosphere can introduce minor temperature fluctuations. Purging the chamber or introducing a flow of cool inert gas will cause a temporary temperature dip that the control system must then work to correct. A well-designed system minimizes this disruption, but it is an inherent factor to consider.

Making the Right Choice for Your Application

Selecting the right furnace requires matching its capabilities to your specific experimental or production goals.

- If your primary focus is maximum precision for small samples: Prioritize a compact furnace with a high-grade PID controller and a verified stability specification of ±1°C.

- If your primary focus is uniform heat treatment of larger parts: Insist on a furnace with multi-zone heating controls, as this is the most effective way to ensure temperature uniformity across a large volume.

- If your primary focus is general-purpose research on a budget: A furnace with a stability of ±5°C is often perfectly adequate for many material processing and heat treatment tasks and offers significant cost savings.

Ultimately, understanding these core principles empowers you to select a furnace based not just on a single specification, but on its proven ability to deliver the reliable outcomes your work demands.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Stability Range | ±1°C to ±5°C, depending on furnace design and controls |

| Key Factors | PID controllers, strategic heating element placement, zone heating, high-performance insulation, and sealing |

| Stability vs. Uniformity | Stability is consistency over time at one point; uniformity is consistency across the chamber space |

| Application Guidance | Max precision for small samples: ±1°C; large parts: multi-zone heating; budget general use: ±5°C |

Ready to enhance your lab's precision and efficiency? Contact KINTEK today to discuss your specific needs! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for reliable, repeatable outcomes. Get in touch now for a tailored solution!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality