In the ceramics industry, atmosphere furnaces are primarily used for critical thermal processes like sintering, debinding (or glue discharge), and annealing. These furnaces allow manufacturers to precisely control the chemical environment during heating, which is essential for creating high-performance ceramic components with specific, repeatable properties.

The core function of an atmosphere furnace in ceramics is not just to heat the material, but to protect it. By replacing air with a controlled gas or vacuum, these furnaces prevent unwanted chemical reactions like oxidation, ensuring the final ceramic part achieves its required purity, strength, and performance.

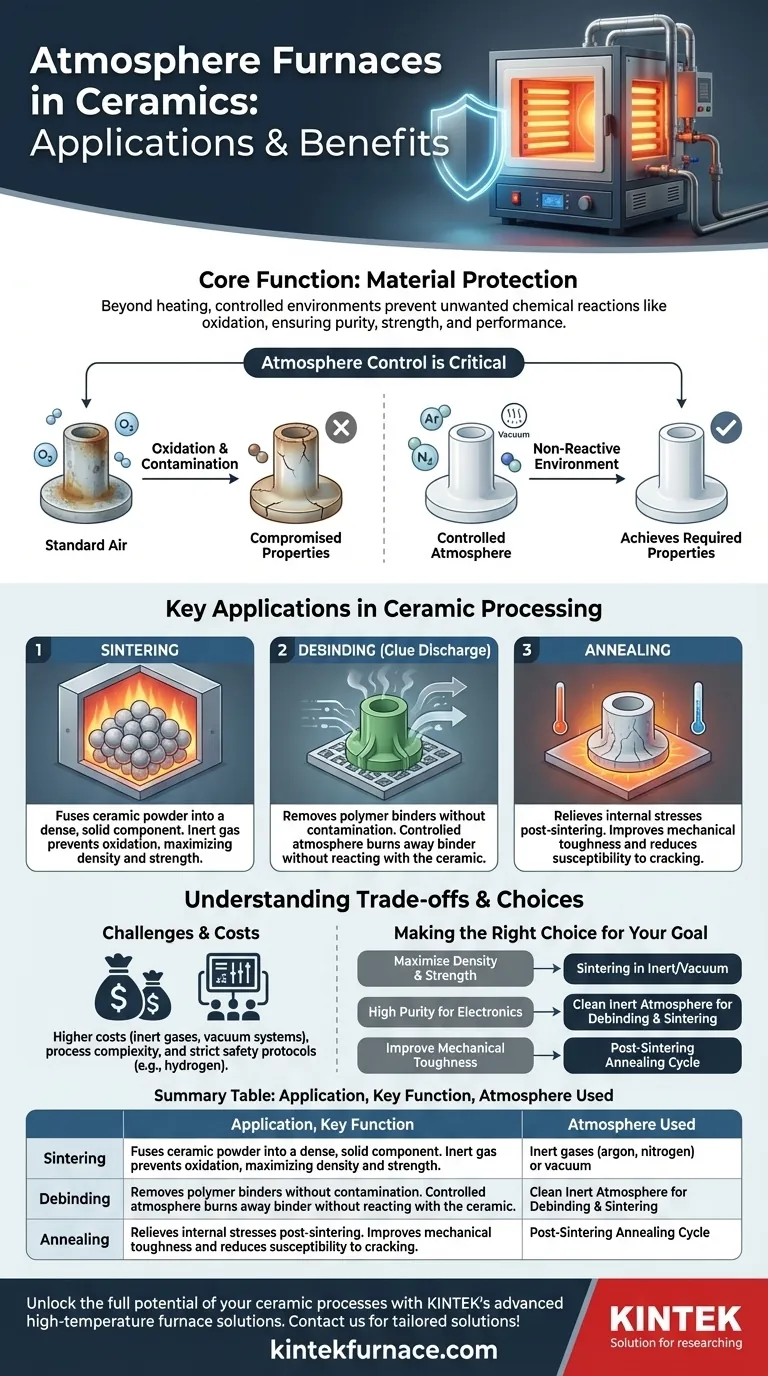

Why Atmosphere Control is Critical for Ceramics

At the high temperatures required for ceramic processing, materials become highly reactive. Exposing them to a standard air atmosphere, which is rich in oxygen, can fundamentally alter or ruin the final product.

Preventing Oxidation and Contamination

The primary reason to use an atmosphere furnace is to prevent oxidation. When ceramic materials react with oxygen at high temperatures, it can lead to discoloration, reduced strength, and altered electrical properties.

Inert gases like argon or nitrogen are used to displace oxygen, creating a non-reactive environment that protects the material's integrity. This is non-negotiable for advanced ceramics used in sensitive applications.

Ensuring Purity for Advanced Applications

Industries like electronics, aerospace, and medical device manufacturing rely on ceramics with exceptionally high purity. An atmosphere furnace prevents airborne contaminants from embedding into the ceramic during firing.

This process ensures that components like semiconductor substrates or aerospace heat shields meet stringent performance and reliability standards.

Achieving Precise Material Properties

The final density, grain structure, and mechanical strength of a ceramic are determined during the thermal cycle.

By controlling the atmosphere, engineers can steer the chemical and physical transformations that occur during heating. This allows for the precise development of material properties tailored to a specific function.

Key Applications in Ceramic Processing

While the principle is consistent, atmosphere furnaces are applied at different stages of ceramic manufacturing to achieve specific outcomes.

Sintering

Sintering is the process of heating compacted ceramic powder to just below its melting point. This causes the individual particles to fuse, creating a dense, solid component.

Using an inert atmosphere during sintering prevents oxidation and ensures the part achieves maximum density and strength.

Debinding (or "Glue Discharge")

Before sintering, many ceramic parts are in a "green" state, held together by a polymer binder. This binder must be removed completely in a process called debinding or binder burnout.

Heating the part in a controlled, inert atmosphere allows the binder to be burned away without reacting with or contaminating the ceramic material itself.

Annealing

Annealing is a heat treatment process performed after sintering. The ceramic is heated and then slowly cooled to relieve internal stresses that may have developed during initial firing.

This improves the material's mechanical toughness and reduces its susceptibility to cracking, which is vital for structural ceramic components.

Understanding the Trade-offs

While essential for high-performance ceramics, using an atmosphere furnace introduces complexities and costs not present with simple air furnaces.

The Cost of a Controlled Atmosphere

Operating an atmosphere furnace is inherently more expensive. The ongoing cost of high-purity inert gases (like argon) and the initial investment in a sealed, vacuum-capable furnace system are significant.

Process Complexity and Safety

Managing gas flow, pressure, and purity requires sophisticated control systems and well-trained operators. Using reducing atmospheres, such as those containing hydrogen, also introduces significant safety protocols that must be strictly followed.

Furnace Selection

The type of furnace—such as a horizontal tube furnace for smaller parts or a larger box-type furnace for bulk processing—must be matched to the specific application. The choice impacts throughput, temperature uniformity, and the efficiency of atmosphere control.

Making the Right Choice for Your Goal

The specific furnace process you use should be directly aligned with the desired properties of your final ceramic component.

- If your primary focus is maximum density and strength: Your key process will be sintering in a tightly controlled inert or vacuum atmosphere to create a fully densified structural part.

- If your primary focus is high purity for electronic components: You must use a clean, inert atmosphere for both debinding and sintering to avoid any contamination that could alter electrical performance.

- If your primary focus is improving mechanical toughness: You will employ a post-sintering annealing cycle to relieve internal stresses and prevent delayed fractures.

Ultimately, mastering the furnace atmosphere is the key to unlocking the full performance potential of advanced ceramic materials.

Summary Table:

| Application | Key Function | Atmosphere Used |

|---|---|---|

| Sintering | Fuses ceramic powder for density and strength | Inert gases (argon, nitrogen) or vacuum |

| Debinding | Removes polymer binders without contamination | Inert gases |

| Annealing | Relieves internal stresses to improve toughness | Inert gases |

Unlock the full potential of your ceramic processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance purity, strength, and efficiency in your lab!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials