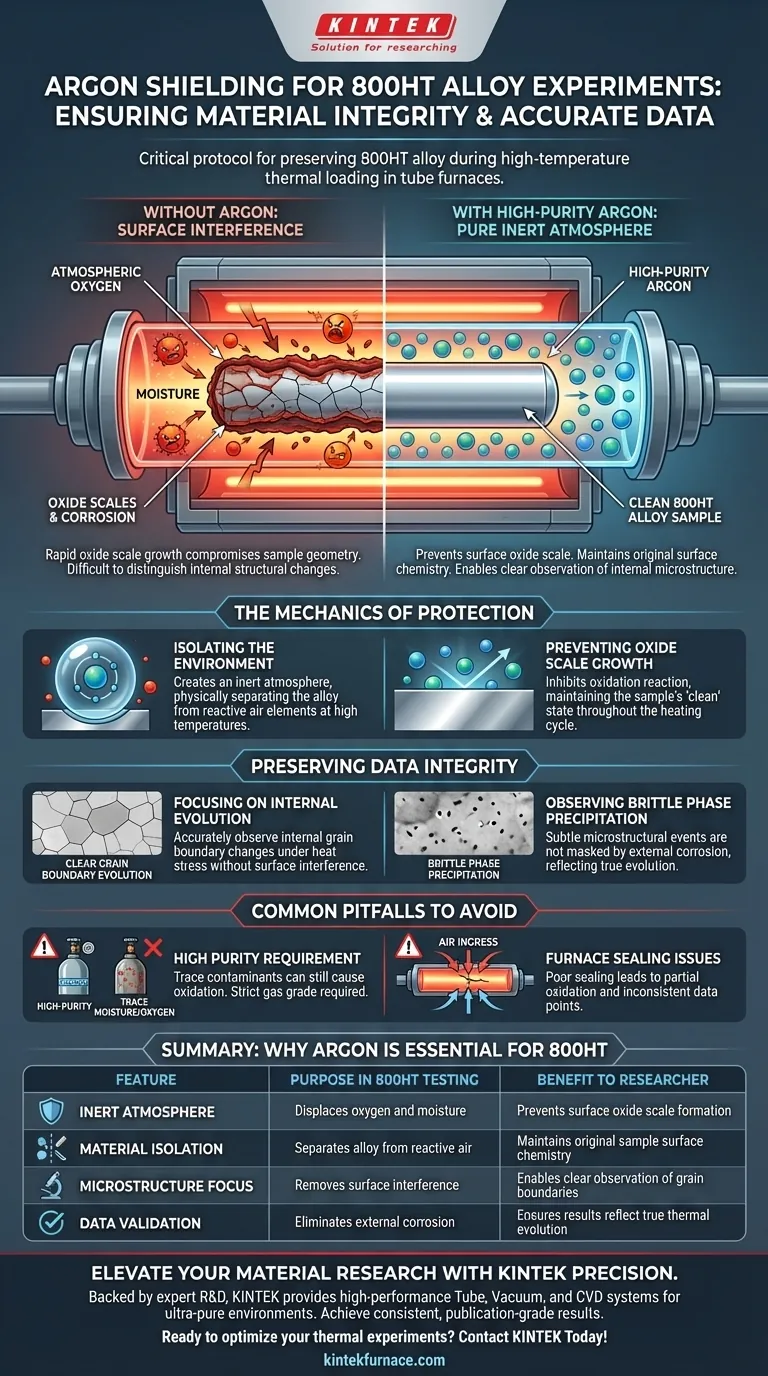

The introduction of argon shielding gas is a critical protocol for preserving the material integrity of 800HT alloy. By flooding the industrial-grade tube furnace with high-purity argon, you effectively displace atmospheric air and isolate the sample during thermal loading. This specific isolation is required to prevent the formation of oxide scales on the alloy's surface, which naturally occur when metals are exposed to oxygen at elevated temperatures.

High-temperature experiments are designed to test the internal limits of a material, but atmospheric oxygen creates surface interference. Argon shielding acts as a barrier, ensuring that the microstructural changes you observe are a result of thermal loading, not surface oxidation.

The Mechanics of Protection

Isolating the Material Environment

At high temperatures, the 800HT alloy is highly reactive to the oxygen present in standard air. Introducing argon creates an inert atmosphere within the furnace chamber. This physically separates the alloy from the reactive elements that would otherwise alter its surface chemistry.

Preventing Oxide Scale Growth

Without a shielding gas, the alloy would rapidly develop oxide scales—layers of corrosion product on the exterior. These scales can be thick and brittle, fundamentally changing the geometry and surface characteristics of your sample. Argon inhibits this chemical reaction entirely, maintaining the sample in its original "clean" state throughout the heating cycle.

Preserving Data Integrity

Focusing on Internal Evolution

The primary goal of these simulations is often to study the material's internal behavior. Researchers need to observe how the internal grain boundaries evolve under heat stress. If the surface is compromised by heavy oxidation, it becomes difficult to distinguish between internal structural changes and surface-level degradation.

Observing Brittle Phase Precipitation

Thermal loading experiments often aim to identify the precipitation of brittle phases within the alloy. Argon shielding ensures that these subtle microstructural events are not masked or influenced by external corrosion. It guarantees that the data collected reflects the true microstructural evolution of the 800HT alloy solely due to temperature and time.

Common Pitfalls to Avoid

The Requirement for High Purity

It is not enough to simply use standard argon; the reference specifies high-purity argon. If the gas contains trace amounts of moisture or oxygen, oxidation can still occur, invalidating the experiment. You must ensure the gas grade meets the strict requirements of the sensitivity of the alloy.

Furnace Sealing Issues

Even with high-purity gas, the protective atmosphere is only as good as the furnace seal. If the tube furnace is not properly sealed, air can ingress and contaminate the environment. This leads to partial oxidation, which can be even more confusing to analyze than full oxidation because it creates inconsistent data points.

Making the Right Choice for Your Goal

To ensure your thermal loading experiments yield valid, publication-grade data, you must align your atmospheric controls with your specific research objectives.

- If your primary focus is internal microstructure: You must use high-purity argon to prevent surface artifacts from obscuring grain boundary evolution.

- If your primary focus is mechanical property retention: You should utilize the shielding gas to ensure that failure modes are driven by thermal aging (brittle phases) rather than surface corrosion cracking.

By controlling the atmosphere, you transform a generic heat test into a precise investigation of material science principles.

Summary Table:

| Feature | Purpose in 800HT Testing | Benefit to Researcher |

|---|---|---|

| Inert Atmosphere | Displaces oxygen and moisture | Prevents surface oxide scale formation |

| Material Isolation | Separates alloy from reactive air | Maintains original sample surface chemistry |

| Microstructure Focus | Removes surface interference | Enables clear observation of grain boundaries |

| Data Validation | Eliminates external corrosion | Ensures results reflect true thermal evolution |

Elevate Your Material Research with KINTEK Precision

Don't let surface oxidation compromise your critical thermal loading data. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Vacuum, and CVD systems designed to maintain the ultra-pure inert environments required for sensitive alloys like 800HT. Whether you need a standard setup or a fully customizable solution for your unique high-temp lab needs, our team is ready to help you achieve consistent, publication-grade results.

Ready to optimize your thermal experiments? Contact KINTEK Today!

Visual Guide

References

- Damian Sierakowski, S. Kąc. Evaluation of the Microstructure and Corrosion Resistance of the 800HT Alloy After Long-Term Operation. DOI: 10.3390/app15169188

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the main components of the temperature control system in the box type annealing atmosphere furnace? Unlock Precise Heat Treatment

- How do high-temperature furnaces facilitate the functionalization of materials? Optimize Biodiesel Catalyst Synthesis

- How does the atmosphere system in a box-type atmosphere furnace work? Master Precise Chemical Control for Material Processing

- Why is controlled atmosphere capability important in an atmosphere furnace? Unlock Precise Material Processing

- What are the commonly used inert gases in atmosphere furnaces? Optimize Your Heat Treatment Process

- What kind of atmosphere is typically used in low vacuum atmosphere furnaces? Optimize Your Heat Treatment with Inert Gases

- What is the pressure range of an atmosphere box furnace under high-pressure conditions? Discover Custom Solutions for Your Lab

- How does the box type annealing atmosphere furnace achieve good temperature uniformity? Optimize Your Heat Treatment Process