At its core, the atmosphere system in a box-type furnace works by replacing the ambient air inside a sealed chamber with a specific, controlled gas. This process involves purging the chamber of oxygen and moisture and then introducing a continuous, low-pressure flow of a desired gas—such as inert argon or a reactive hydrogen mixture—to create a precise chemical environment for high-temperature material processing.

The primary purpose of an atmosphere system is not just to fill a box with gas, but to gain absolute control over the chemical reactions that occur at high temperatures. It allows you to protect materials from damage, such as oxidation, or actively promote desired changes, like sintering.

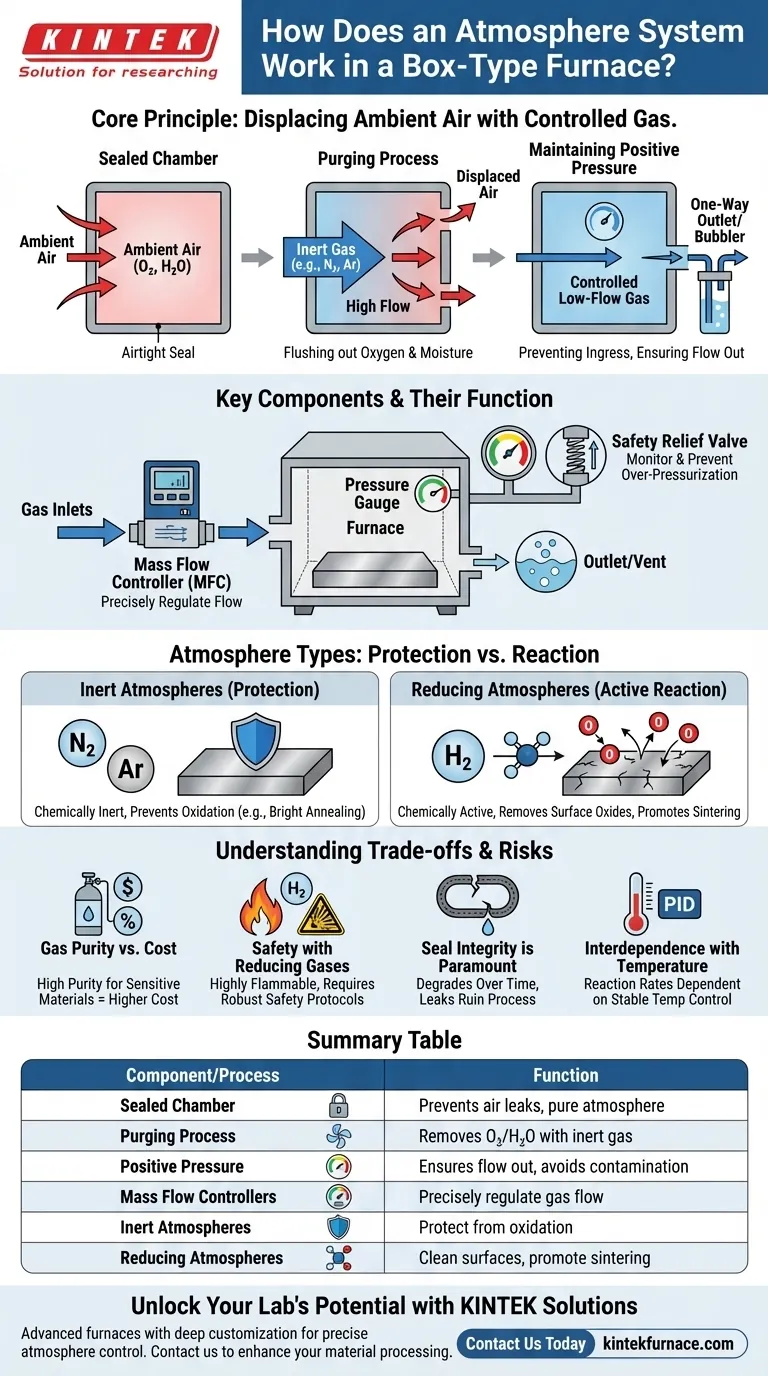

The Core Principle: Displacing Unwanted Air

The entire function of an atmosphere system hinges on creating and maintaining a chemically pure environment, free from the reactive elements in normal air.

The Sealed Chamber

First, the furnace must be a tightly sealed, airtight vessel. Any leaks would allow oxygen and moisture from the outside air to enter, contaminating the controlled atmosphere and compromising the process.

The Purging Process

Before heating begins, the system must remove the existing air from the chamber. This is typically done by flushing the chamber with a high flow of an inert gas, like nitrogen or argon, which displaces the oxygen and other contaminants.

Maintaining Positive Pressure

Once purged, a continuous, low-flow of the desired gas is introduced. This flow is managed to maintain a slight positive pressure inside the furnace, ensuring that if any microscopic leaks exist, gas will flow out rather than air leaking in.

Key Components and Their Function

A complete atmosphere system is more than just a gas cylinder and a tube. It relies on several components working in unison to achieve precise control.

Gas Inlets and Outlets

These are the physical ports for introducing the controlled gas and for venting the purged air and process byproducts. The outlet is often a simple one-way relief valve or a bubbler to show gas flow.

Flow Controllers

To "precisely regulate the flow," as required for repeatable results, modern furnaces use Mass Flow Controllers (MFCs). These devices measure and control the volume of gas entering the furnace, ensuring the atmosphere remains stable throughout the process.

Pressure Gauges and Safety Valves

A pressure gauge monitors the internal chamber pressure, confirming that a slight positive pressure is maintained. A safety relief valve is also critical to prevent over-pressurization, especially during heating when gases expand.

The Role of Different Atmospheres

The choice of gas is determined entirely by the desired outcome of the heat treatment process. Each type serves a distinct chemical purpose.

Inert Atmospheres (Protection)

Gases like Nitrogen (N₂) and Argon (Ar) are chemically inert. They do not react with the materials in the furnace. Their sole purpose is to create a protective blanket that prevents oxidation and other unwanted chemical reactions that would occur in the presence of air. This is crucial for processes like bright annealing.

Reducing Atmospheres (Active Reaction)

A reducing atmosphere, typically a mixture of an inert gas with Hydrogen (H₂), is chemically active. Hydrogen actively strips oxygen atoms from the surface of materials, a process known as "reduction." This is used to clean surfaces, reverse light oxidation, and promote sintering by creating pure, active particle surfaces that bond more easily.

Understanding the Trade-offs and Risks

While powerful, atmosphere control introduces complexities and risks that must be managed carefully.

Gas Purity vs. Cost

The purity of the source gas is critical. For highly sensitive materials like titanium, even trace amounts of oxygen can cause damage. Using high-purity (e.g., 99.999%) gas is effective but significantly more expensive.

Safety with Reducing Gases

Hydrogen is highly flammable and can be explosive when mixed with air. Systems using reducing gases require robust safety protocols, including proper ventilation, leak detection, and carefully managed purging cycles to ensure no explosive mixtures are present during heating.

Seal Integrity is Paramount

The effectiveness of the entire system depends on the furnace's seals. Gaskets and door seals degrade over time with thermal cycling. A small, undetected leak can ruin a multi-hour process, wasting time, materials, and expensive gas.

Interdependence with Temperature Control

The atmosphere and temperature systems are separate but deeply connected. The rate of chemical reactions is dictated by temperature. Therefore, a stable and accurate temperature, managed by the furnace's PID temperature controller, is required for the atmospheric reactions to be predictable and repeatable.

Making the Right Choice for Your Process

Your process goal dictates the type of atmosphere system you need.

- If your primary focus is preventing oxidation (e.g., annealing, brazing): An inert gas atmosphere using nitrogen or argon is your most direct and cost-effective solution.

- If your primary focus is active surface cleaning or sintering: A reducing atmosphere containing hydrogen is necessary to chemically remove surface oxides and promote bonding.

- If your primary focus is process repeatability and precision: Invest in a system with high-quality mass flow controllers and ensure the furnace chamber has a certified low leak rate.

By mastering the furnace's chemical environment, you gain direct control over the outcome of your material processing.

Summary Table:

| Component/Process | Function |

|---|---|

| Sealed Chamber | Prevents air leaks to maintain a pure atmosphere |

| Purging Process | Removes oxygen and moisture using inert gases |

| Positive Pressure | Ensures gas flows out, not air in, to avoid contamination |

| Mass Flow Controllers | Precisely regulate gas flow for stable atmosphere |

| Inert Atmospheres (e.g., N₂, Ar) | Protect materials from oxidation |

| Reducing Atmospheres (e.g., H₂ mix) | Actively clean surfaces and promote sintering |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, from preventing oxidation to promoting sintering with controlled atmospheres. Don't let process inconsistencies hold you back—contact us today to discuss how our tailored solutions can enhance your material processing efficiency and results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality