In short, low vacuum atmosphere furnaces operate using an inert gas, most commonly nitrogen or argon. The primary function is not to maintain a deep vacuum, but to first remove the reactive atmosphere (air) and then replace it with a non-reactive gas to protect the material during heat treatment.

The term "low vacuum" can be misleading. These furnaces are not designed to operate in a vacuum; they use a vacuum pump as an efficient tool to purge oxygen before backfilling with a protective, inert atmosphere where the actual process takes place.

The Purpose of the Atmosphere

The core function of a low vacuum atmosphere furnace is to control the chemical environment around a part during heating. This is crucial for preventing unwanted reactions that can compromise the material's integrity.

Preventing Oxidation and Reactions

When metals are heated, their reactivity with the surrounding atmosphere increases dramatically. The oxygen in ambient air will rapidly form oxides on the surface of most metals, leading to scaling, discoloration, and poor surface quality.

By first evacuating the chamber to a low vacuum level, the vast majority of the air—and therefore oxygen—is removed. The chamber is then backfilled with an inert gas like nitrogen or argon, creating a non-reactive environment for the heating process.

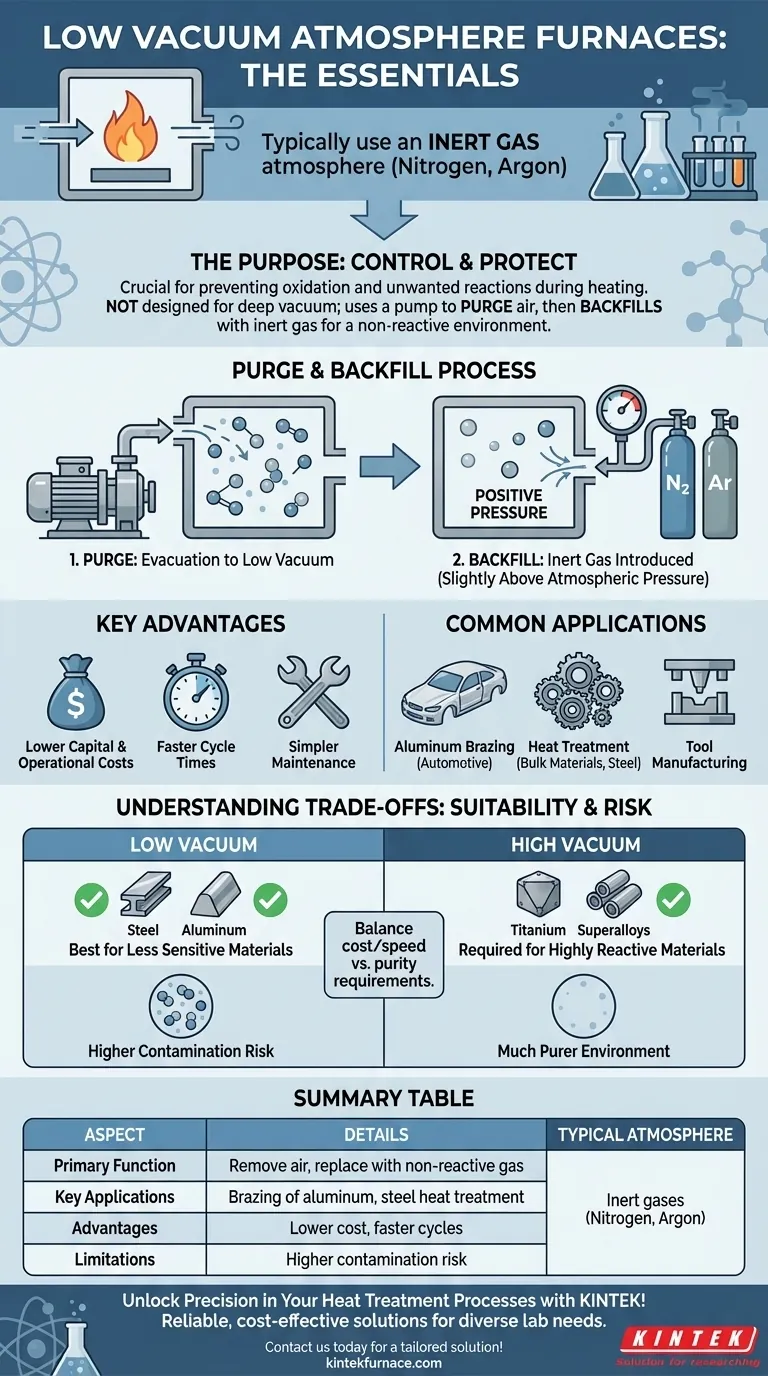

The Purge and Backfill Process

The operational cycle is a two-step process. First, a mechanical vacuum pump, such as a rotary vane pump, evacuates the furnace chamber. This "pump-down" is relatively fast because it only needs to reach a low vacuum level.

Once the air is removed, the inert gas is introduced, bringing the chamber back up to a pressure slightly above atmospheric. This positive pressure ensures that no outside air can leak into the furnace during the heat treatment cycle.

When to Choose a Low Vacuum System

A low vacuum atmosphere furnace represents a pragmatic balance between cost, speed, and process quality. It is chosen when absolute purity is not required, but atmospheric protection is essential.

Key Advantages

The primary benefits are economic and operational. Compared to high vacuum systems, they offer lower capital and operational costs.

They also have significantly faster cycle times because achieving a low vacuum is much quicker than pulling a deep, high vacuum. Maintenance is also simpler due to the less demanding nature of the components.

Common Applications

These furnaces are workhorses in many industries. They are widely used for processes like the brazing of aluminum parts in the automotive sector, general heat treatment of bulk materials like steel, and various applications in tool manufacturing.

Understanding the Trade-offs

The primary limitation of this technology is its suitability. It is an excellent tool for many applications but is inappropriate for others that demand a higher level of purity.

Inherent Risk of Contamination

A "low vacuum" is not an empty space; it still contains a significant number of residual gas molecules. This means the environment is never perfectly pure.

Compared to a high vacuum furnace, there is a higher risk of contamination from these residual gases. This makes the system unsuitable for processing highly sensitive or reactive materials where even trace amounts of impurities can cause failure.

Material Compatibility

Low vacuum systems are best suited for less sensitive materials, such as most steels and aluminum alloys, where the primary goal is simply to prevent gross oxidation.

Materials that are extremely reactive at high temperatures, such as titanium, refractory metals, or certain superalloys, require the much purer environment provided by a high vacuum furnace.

Making the Right Choice for Your Process

Selecting the correct furnace technology comes down to balancing the requirements of your material against your operational goals for cost and throughput.

- If your primary focus is cost-effective heat treatment of robust materials like steel: A low vacuum atmosphere furnace using nitrogen is the industry standard and the most economical choice.

- If your primary focus is high-purity processing of reactive materials like titanium: A high-vacuum furnace is non-negotiable to prevent catastrophic contamination.

- If your primary focus is high-volume aluminum brazing: A low vacuum atmosphere system provides the necessary protection from oxidation with the speed required for production environments.

Ultimately, understanding that a low vacuum furnace is an atmospheric control system—not a true vacuum system—is the key to applying it correctly.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Atmosphere | Inert gases like nitrogen or argon |

| Primary Function | Remove air and replace with non-reactive gas to prevent oxidation |

| Key Applications | Brazing of aluminum, heat treatment of steels, tool manufacturing |

| Advantages | Lower cost, faster cycle times, simpler maintenance |

| Limitations | Higher contamination risk, not for highly sensitive materials |

Unlock Precision in Your Heat Treatment Processes with KINTEK!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're working with steel, aluminum, or other materials, we deliver reliable, cost-effective systems that enhance efficiency and protect your samples from oxidation.

Ready to elevate your lab's performance? Contact us today for a tailored solution!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance