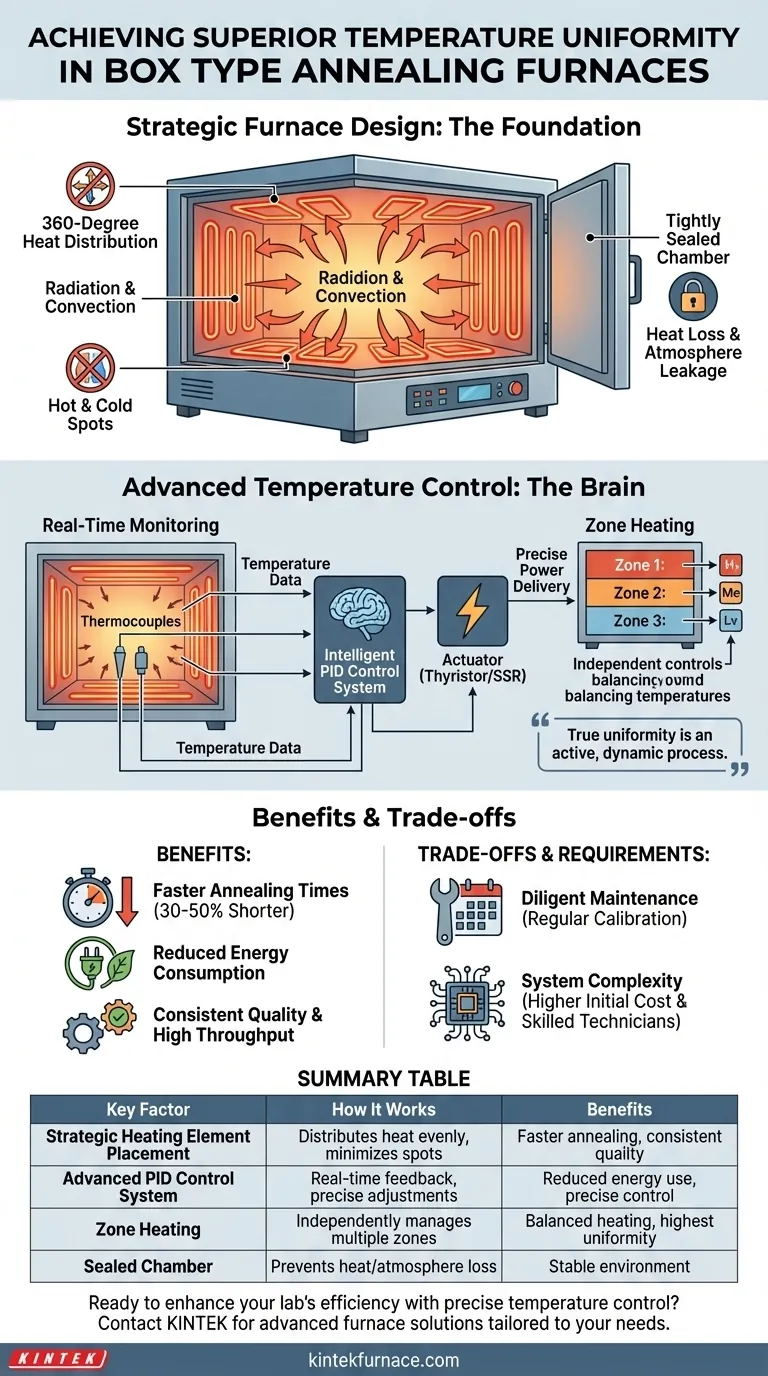

To achieve superior temperature uniformity, a box type annealing furnace integrates three core principles. It uses a strategic physical layout of heating elements, an intelligent and responsive digital control system, and a robustly insulated and sealed chamber to create and maintain a consistent thermal environment.

True temperature uniformity is not a static feature; it is an active, dynamic process. It results from the deliberate combination of smart furnace construction and a responsive digital control system that constantly measures and corrects temperature deviations across the entire chamber.

The Foundation: Strategic Furnace Design

The physical construction of the furnace is the first line of defense in the battle against temperature gradients. Without a sound design, no control system can compensate effectively.

Distributing Heat Sources Evenly

The most fundamental principle is the strategic placement of heating elements. These are evenly distributed on the walls, top, and bottom of the furnace interior.

This 360-degree approach ensures that heat is delivered from all directions, minimizing the hot and cold spots that would occur if heat originated from a single source.

Leveraging Radiation and Convection

These furnaces use a combination of radiation and convection heating. Radiant heat travels in straight lines to warm the surface of the workload, while convection circulates the heated atmosphere within the chamber.

This dual-method approach ensures heat penetrates complex shapes and dense loads more effectively, promoting a uniform temperature throughout the material being annealed.

Ensuring a Tightly Sealed Chamber

A reliable sealing structure on the furnace door is critical. This prevents both heat loss to the outside environment and leakage of the protective atmosphere.

By maintaining a closed, stable system, the furnace minimizes external variables that could disrupt the internal temperature balance.

The Brain: Advanced Temperature Control

A well-designed furnace chamber creates the potential for uniformity. The temperature control system is what realizes that potential in real-time.

Real-Time Monitoring with Sensors

Temperature sensors, such as thermocouples or thermistors, are placed at key locations inside the furnace. They provide constant, real-time temperature data to the control system.

This continuous feedback loop is the sensory input that allows the system to know precisely what is happening inside the chamber at all times.

Intelligent Adjustments with PID Control

Modern furnaces use a PID (Proportional-Integral-Derivative) control algorithm. This is a sophisticated method that goes beyond simple on/off control.

The PID controller analyzes the current temperature, how far it is from the setpoint, and the rate at which it is changing. It then predicts the required energy input to correct deviations smoothly and prevent overshooting the target temperature.

Precise Power Delivery

The PID controller's decisions are executed by an actuator, typically a thyristor regulator or a solid-state relay.

These components precisely modulate the electrical power sent to the heating elements, allowing for minute and rapid adjustments that keep the temperature exceptionally stable.

The Power of Zone Heating

For larger furnaces or highly sensitive processes, zone heating is employed. The furnace is divided into multiple heating "zones," each with its own dedicated heating elements and sensors.

The control system can then independently manage the power output to each zone, allowing it to actively balance a hot area by reducing its power while simultaneously boosting a cooler area. This provides the highest possible degree of temperature uniformity.

Understanding the Consequences and Trade-offs

Achieving excellent uniformity is not just a technical feature; it has direct operational consequences and comes with certain requirements.

The Benefit: Faster, More Consistent Results

Because the entire workload reaches the target temperature evenly and predictably, annealing times can be shortened by 30% to 50% compared to less uniform furnaces. This directly translates to higher throughput and more consistent metallurgical properties in the finished parts.

The Benefit: Reduced Energy Consumption

Precise control prevents the furnace from overshooting its temperature setpoint, and efficient insulation prevents heat loss. This combination means less wasted energy is used to maintain the target temperature, reducing operational costs.

The Requirement: Diligent Maintenance

Uniformity is not a "set it and forget it" feature. The system's accuracy depends on the health of its components. Regular calibration of temperature sensors and inspection of heating elements are essential to maintain performance over time.

The Cost: System Complexity

The advanced systems that enable uniformity—PID controllers, multiple sensors, and zone heating logic—are inherently more complex than basic furnace controls. This can translate to a higher initial investment and require more skilled technicians for troubleshooting and maintenance.

Making the Right Choice for Your Process

Matching the furnace's capabilities to your specific application is key to maximizing its value. Consider your primary goal to determine which features are most critical.

- If your primary focus is processing large or complex parts: Prioritize a furnace with multi-zone heating for the most granular control over temperature distribution.

- If your primary focus is high-throughput production: Look for a system with a fast-responding PID controller and efficient heating elements to minimize cycle times and energy use.

- If your primary focus is long-term reliability and consistency: Ensure the furnace design allows for easy access for sensor calibration and element inspection.

Understanding how these systems work together empowers you to achieve more predictable, efficient, and higher-quality results from your thermal processing operations.

Summary Table:

| Key Factor | How It Achieves Uniformity |

|---|---|

| Strategic Heating Element Placement | Distributes heat evenly from all directions to minimize hot/cold spots |

| Advanced PID Control System | Uses real-time feedback for precise temperature adjustments |

| Zone Heating | Independently manages multiple zones for balanced heating |

| Sealed Chamber | Prevents heat loss and maintains stable atmosphere |

| Benefits | Faster annealing (30-50% shorter times), reduced energy use, consistent quality |

Ready to enhance your lab's efficiency with precise temperature control? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored furnace solutions can optimize your annealing processes and deliver superior results!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment