In a standard sense, there is no defined high-pressure range for a typical atmosphere box furnace. These furnaces are primarily designed for atmospheric or vacuum conditions. Operations requiring significantly elevated pressure demand highly specialized, custom-built equipment where the pressure range is engineered specifically for the target application, as the furnace must be constructed as a certified pressure vessel.

The core issue is a mismatch in terminology. The term "atmosphere box furnace" almost always refers to equipment operating at or below atmospheric pressure. True high-pressure work is a separate engineering discipline requiring custom-designed systems, not off-the-shelf furnaces.

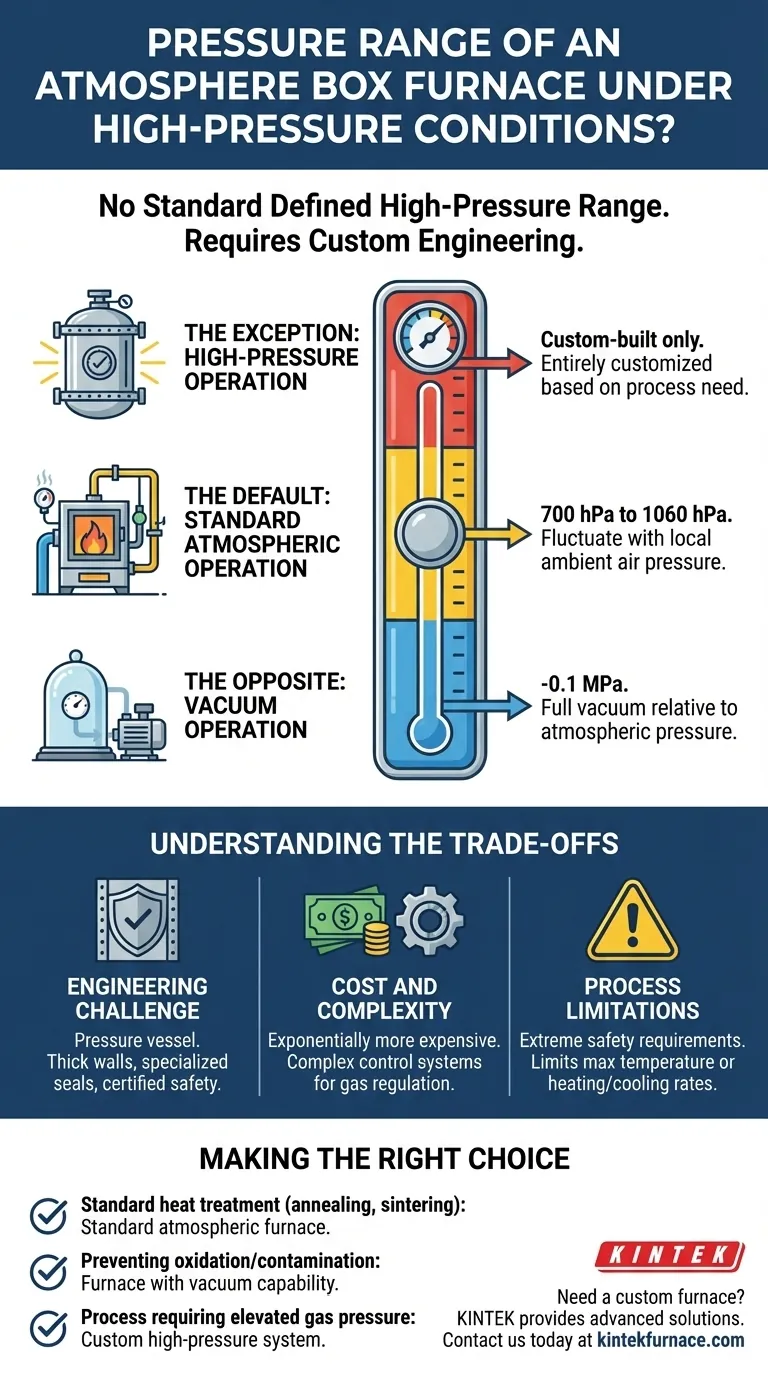

Deconstructing Pressure in a Box Furnace

To understand the capabilities of this equipment, it's essential to separate its operation into three distinct pressure regimes. Each serves a fundamentally different purpose in material processing.

The Default: Standard Atmospheric Operation

A standard atmosphere box furnace operates at pressures that fluctuate with the local ambient air pressure.

This range is typically between 700 hPa and 1060 hPa. This is suitable for common heat treatment processes like annealing or sintering where the presence of a specific gas (like nitrogen or argon) at normal pressure is sufficient.

The Opposite: Vacuum Operation

Many atmosphere furnaces are also capable of creating a vacuum to remove reactive gases like oxygen.

These systems can often achieve a vacuum level of -0.1 MPa (a full vacuum relative to atmospheric pressure). This environment is critical for processing materials that are sensitive to oxidation or contamination.

The Exception: High-Pressure Operation

This is the least common application for a "box furnace" and represents a significant engineering challenge.

High-pressure operation is not a feature of standard equipment. It requires a furnace built from the ground up to withstand internal forces, with a pressure range that is entirely customized based on the specific process need.

Understanding the Trade-offs

Moving from atmospheric pressure to high pressure isn't a simple upgrade; it fundamentally changes the equipment's design, cost, and complexity.

The Engineering Challenge

A standard furnace chamber is designed simply to contain heat and a controlled gas.

A high-pressure furnace chamber is a pressure vessel. It requires thick walls, reinforced structures, specialized seals, and certified safety systems to prevent catastrophic failure, making it a completely different class of equipment.

Cost and Complexity

The materials and engineering required for high-pressure systems are exponentially more expensive than for standard atmospheric or vacuum furnaces.

Control systems also become more complex, as they must manage not only temperature but also the precise regulation of gas flow into and out of a pressurized environment.

Process Limitations

While high pressure can enable specific reactions or material densification, it is not a universally better environment.

The extreme requirements for safety and structural integrity often limit other factors, such as maximum achievable temperature or the rate of heating and cooling.

Making the Right Choice for Your Goal

Selecting the correct equipment requires a clear understanding of your primary processing objective.

- If your primary focus is standard heat treatment like annealing or sintering: A standard furnace operating at atmospheric pressure is the correct and most cost-effective tool.

- If your primary focus is preventing oxidation or contamination: A furnace with vacuum capability is necessary to ensure a pure processing environment.

- If your primary focus is a process that requires elevated gas pressure: You must partner with a specialized manufacturer to design and build a custom high-pressure system tailored to your exact needs.

Understanding these distinct pressure regimes is the first step toward selecting the correct tool for your specific material processing goal.

Summary Table:

| Pressure Regime | Typical Range | Key Applications |

|---|---|---|

| Standard Atmospheric | 700 hPa to 1060 hPa | Annealing, sintering in controlled gases |

| Vacuum Operation | -0.1 MPa | Preventing oxidation, contamination |

| High-Pressure Operation | Custom-built only | Specialized processes requiring elevated pressure |

Need a high-pressure furnace for your unique experiments? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your specific requirements. Contact us today to discuss how we can enhance your lab's capabilities!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas