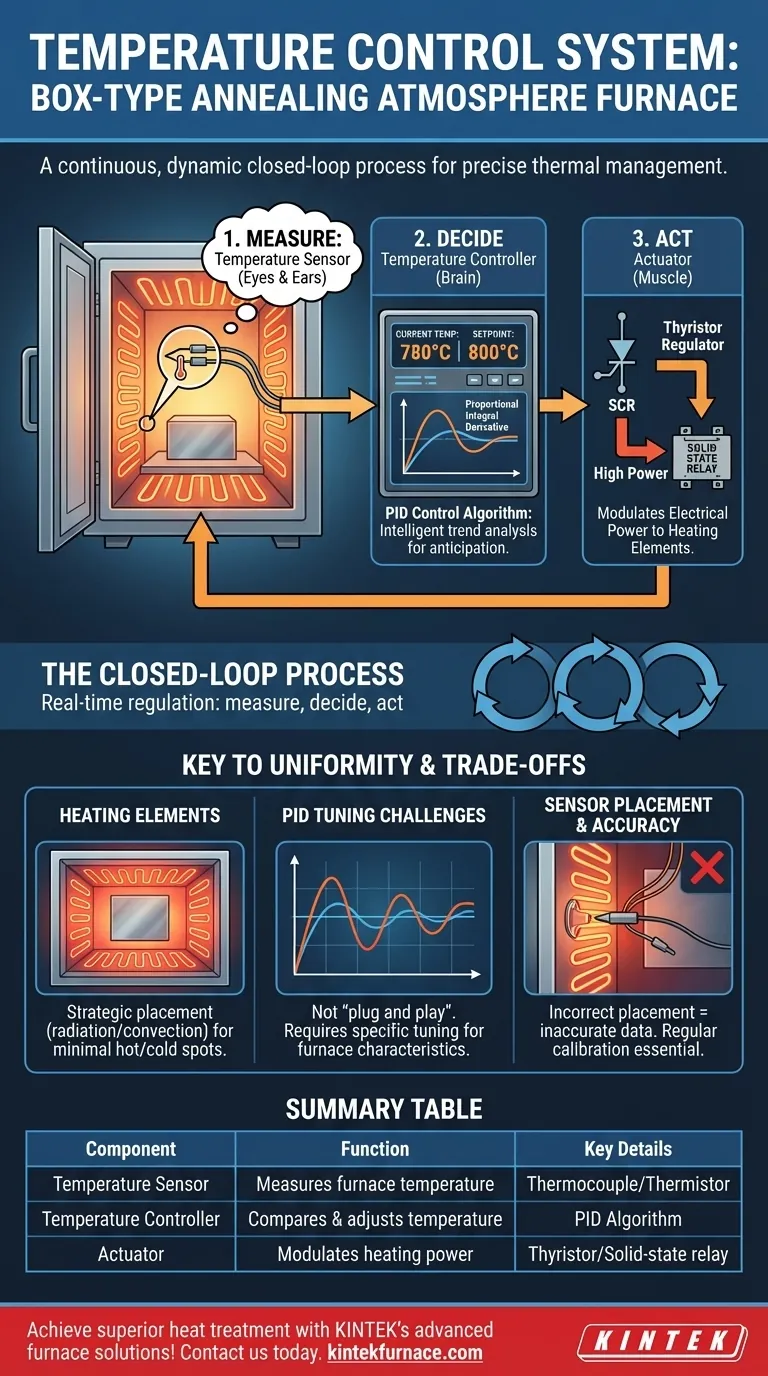

At its core, the temperature control system in a box-type annealing atmosphere furnace is composed of three primary components: a temperature sensor, a temperature controller, and an actuator. This system works in a continuous feedback loop to measure the furnace's internal temperature, compare it to the desired setting, and precisely adjust the heating power to maintain exact thermal conditions required for the annealing process.

The system is not merely a collection of parts, but a dynamic, closed-loop process. Understanding how the sensor, controller, and actuator interact is the key to achieving the repeatable and uniform heating essential for successful material heat treatment.

How the System Works: A Closed-Loop Process

The entire purpose of the temperature control system is to regulate the furnace temperature in real time. It achieves this by constantly repeating a three-step cycle: measure, decide, and act. This ensures the temperature follows the programmed profile, whether it's rising, holding steady, or cooling.

Step 1: Measuring Temperature (The Sensor)

The system's "eyes and ears" inside the furnace is the temperature sensor. This component provides the raw data that drives every decision.

Typically, this is a thermocouple or a thermistor. It is placed strategically within the furnace chamber to get an accurate reading of the temperature the workpiece is experiencing. This real-time measurement is the first and most critical step in the control loop.

Step 2: Making Decisions (The Controller)

The temperature controller acts as the brain of the operation. It receives the temperature reading from the sensor and compares it to the target temperature you have set (the "setpoint").

Modern furnaces use a PID (Proportional-Integral-Derivative) control algorithm. This intelligent algorithm doesn't just look at the current temperature deviation; it also analyzes the trend (how fast the temperature is changing) to anticipate and prevent overshooting or undershooting the target.

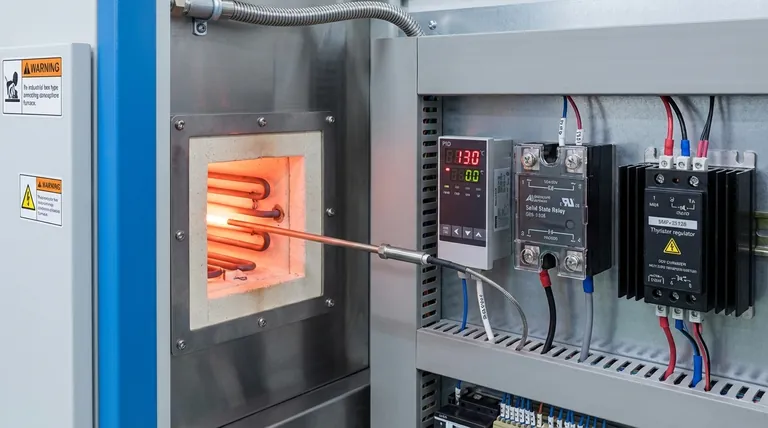

Step 3: Taking Action (The Actuator)

Based on the controller's decision, the actuator serves as the muscle. It translates the controller's low-voltage signal into a high-power action that directly affects the heating elements.

The actuator is usually a thyristor regulator (also known as an SCR) or a solid-state relay. Its job is to precisely modulate the electrical power flowing to the furnace's heating elements, increasing or decreasing heat output as needed to match the controller's commands.

The Importance of Uniformity

The control system's precision is meaningless if the heat isn't distributed evenly. The physical design of the furnace works in concert with the control system to ensure temperature uniformity.

The Role of Heating Elements

Heating elements, typically resistance wires, are strategically arranged around the furnace chamber—often on the sides, bottom, or top. This placement is designed to transfer heat to the workpieces through both radiation and convection, minimizing hot or cold spots.

How the Control System Supports Uniformity

A well-tuned temperature control system prevents the heating elements from running at maximum power for too long, which can create localized hotspots. By making small, rapid adjustments, the system promotes a gentle and even soaking of the entire workpiece at the target temperature.

Understanding the Trade-offs

A perfect temperature profile depends on more than just high-quality components; it requires proper setup and an awareness of potential pitfalls.

Sensor Placement and Accuracy

An incorrectly placed sensor will feed the controller inaccurate data. If the sensor is too close to a heating element or the door, the control system will be regulating the wrong temperature, leading to improperly treated materials. Regular calibration is essential.

PID Tuning Challenges

A PID controller is not "plug and play." It must be tuned for the specific furnace's thermal characteristics. Poor tuning can lead to temperature overshooting the setpoint, slow response times, or constant temperature oscillations, all of which compromise the annealing process.

Actuator Response and Lifespan

While both thyristors and solid-state relays are effective, they have different characteristics. Thyristors offer very fine power control, while solid-state relays provide simple on/off control at high speeds. The choice can impact the fineness of control and the long-term reliability of the system.

Making the Right Choice for Your Goal

Understanding this system empowers you to diagnose issues and ensure optimal performance based on your primary objective.

- If your primary focus is process repeatability: A well-tuned PID controller is your most critical asset for ensuring every batch is treated identically.

- If your primary focus is material quality: Precise sensor placement and regular system calibration are non-negotiable to guarantee the workpiece reaches the correct temperature uniformly.

- If your primary focus is energy efficiency: A modern thyristor-based actuator paired with an intelligent PID controller will minimize wasted power by avoiding drastic temperature overshoots.

By viewing these components as an interconnected system, you can achieve precise and reliable control over your heat treatment outcomes.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Temperature Sensor | Measures furnace temperature | Typically a thermocouple or thermistor for real-time data |

| Temperature Controller | Compares and adjusts temperature | Uses PID algorithm for precise control and stability |

| Actuator | Modulates heating power | Often a thyristor regulator or solid-state relay |

Achieve superior heat treatment with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance your process repeatability and material quality!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab