In short, controlled atmosphere capability is important because it allows you to precisely manage the gas environment inside a furnace, preventing unwanted chemical reactions like oxidation. This control is essential for protecting the integrity of a material or for enabling specific high-temperature processes like annealing, sintering, or chemical vapor deposition (CVD) that would otherwise fail in ambient air.

The fundamental role of an atmosphere furnace is to treat heat as a tool and atmosphere as a variable. By controlling the gas environment, you transform the furnace from a simple oven into a precise instrument for manipulating material chemistry at high temperatures.

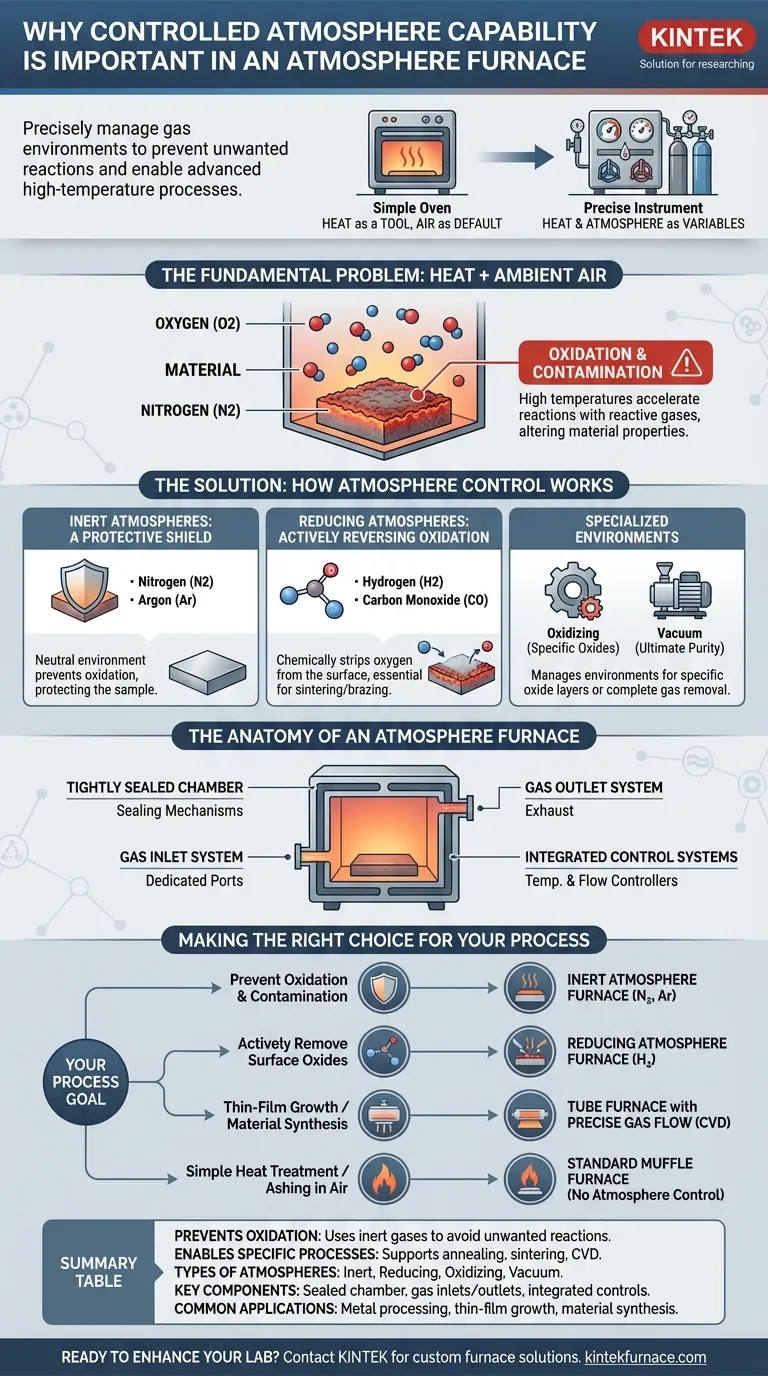

The Fundamental Problem: Heat and Air

High temperatures act as a catalyst, dramatically accelerating chemical reactions. When you heat a material in ambient air, you are exposing it to a reactive mixture of gases, primarily oxygen and nitrogen.

The Inevitability of Oxidation

For many materials, especially metals, heating in the presence of oxygen leads to oxidation—the formation of an oxide layer on the surface. This can be a form of contamination, altering the material's structural, electrical, or chemical properties in undesirable ways.

A controlled atmosphere furnace prevents this by replacing the air with a non-reactive or specifically chosen reactive gas.

Enabling Specific Chemical Processes

Some advanced processes don't just require the absence of air; they require the presence of specific gases to work. For example, chemical vapor deposition (CVD) involves flowing precursor gases over a substrate at high temperatures to create a thin film. This is impossible without precise atmospheric control.

How Atmosphere Control Provides the Solution

An atmosphere furnace gives you a toolkit of gas environments, each serving a distinct purpose. This control is what separates it from a standard muffle furnace, which primarily heats a sample uniformly in air.

Inert Atmospheres: A Protective Shield

The most common function is to create an inert atmosphere. Gases like nitrogen (N2) and argon (Ar) are non-reactive.

By filling the furnace chamber with one of these gases, you create a neutral environment that prevents oxidation and other unwanted reactions, effectively protecting the sample as it's heated.

Reducing Atmospheres: Actively Reversing Oxidation

Sometimes, you need to go a step further than just preventing oxidation; you may need to actively remove it. Reducing atmospheres, which often contain hydrogen (H2) or carbon monoxide (CO), chemically strip oxygen atoms from a material's surface.

This is critical for processes where even a minuscule amount of surface oxide can ruin the outcome, such as in certain types of metal sintering or brazing.

Other Specialized Environments

Beyond inert and reducing, these furnaces can also manage other environments. This includes oxidizing atmospheres when a specific oxide layer is desired, or vacuum conditions to remove all gases entirely for ultimate purity.

The Anatomy of an Atmosphere Furnace

The ability to control the atmosphere is not a feature but a fundamental design principle, built upon several key components.

A Tightly Sealed Chamber

Unlike a basic muffle furnace, an atmosphere furnace (whether a box or tube design) features a heating chamber with robust sealing mechanisms. These seals are critical for preventing ambient air from leaking in and contaminating the controlled environment.

Gas Inlet and Outlet Systems

The furnace is equipped with dedicated ports for introducing specific gases (inlets) and exhausting them (outlets). This allows for purging the chamber of air before a process begins and maintaining a constant flow of the desired gas during the heating cycle.

Integrated Control Systems

Advanced models integrate temperature controllers and gas flow controllers. This allows operators to run programmable recipes where both the temperature and the atmospheric composition change automatically over time, ensuring process repeatability and reliability.

Understanding the Trade-offs

While powerful, an atmosphere furnace isn't always the necessary choice. Understanding its trade-offs is key to making an informed decision.

Added Complexity and Cost

The components required for atmosphere control—gas delivery systems, seals, and safety interlocks—add significant complexity and cost compared to a simple furnace that only heats in air.

Safety Considerations

Working with combustible gases like hydrogen introduces significant safety risks. Proper ventilation, leak detection, and safety protocols are non-negotiable, which adds to the operational overhead.

When a Simpler Furnace Is Enough

For applications where reacting with air is either irrelevant or the desired outcome, a controlled atmosphere is unnecessary. A classic example is ash content determination, where a sample is intentionally burned in a muffle furnace to measure the non-combustible residue.

Making the Right Choice for Your Process

Your choice of furnace should be dictated entirely by the chemical requirements of your thermal process.

- If your primary focus is preventing oxidation and contamination: You need a furnace with the capability to provide an inert atmosphere of nitrogen or argon for processes like annealing or sintering.

- If your primary focus is actively removing surface oxides: You require a furnace designed to safely handle reducing atmospheres containing hydrogen.

- If your primary focus is thin-film growth or material synthesis: A tube furnace with precise gas flow control is essential for processes like chemical vapor deposition (CVD).

- If your primary focus is simple heat treatment or ashing in air: A standard, more economical muffle furnace without atmosphere control is the appropriate tool.

Ultimately, controlling the atmosphere gives you control over your material's final properties.

Summary Table:

| Key Aspect | Description |

|---|---|

| Prevents Oxidation | Uses inert gases like nitrogen or argon to avoid unwanted chemical reactions during heating. |

| Enables Specific Processes | Supports annealing, sintering, and CVD by allowing precise gas environment control. |

| Types of Atmospheres | Includes inert, reducing (e.g., hydrogen), and oxidizing environments for varied applications. |

| Key Components | Sealed chamber, gas inlets/outlets, and integrated control systems for reliable operation. |

| Common Applications | Metal processing, thin-film growth, and high-temperature material synthesis. |

Ready to enhance your lab's capabilities with a custom atmosphere furnace?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization to meet unique experimental requirements. Whether you're preventing oxidation or enabling complex processes like CVD, we have the expertise to deliver reliable, precise results.

Contact us today to discuss how we can help optimize your thermal processes and achieve superior material outcomes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality