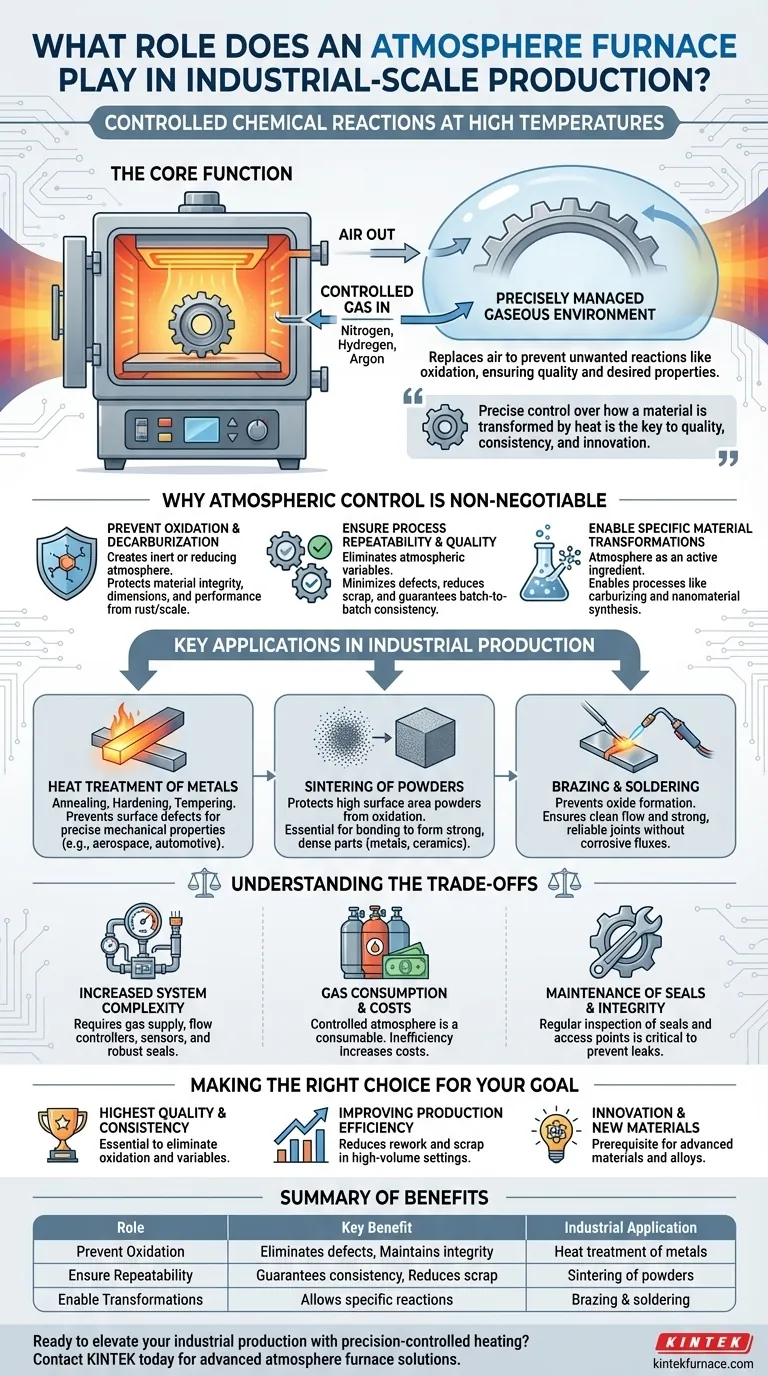

At its core, an atmosphere furnace is an industrial tool for controlling chemical reactions. Its primary role in large-scale production is to enable high-temperature material processing by creating a precisely managed gaseous environment. This prevents unwanted reactions like oxidation, ensuring the final product meets exacting quality standards and possesses the desired properties.

The fundamental problem with heating materials is that air itself becomes a reactive chemical. An atmosphere furnace solves this by replacing the air with a specific, controlled gas, giving manufacturers precise control over how a material is transformed by heat. This control is the key to quality, consistency, and innovation in mass production.

Why Atmospheric Control is Non-Negotiable

A standard furnace heats material in ambient air. An atmosphere furnace goes a critical step further by creating a sealed chamber where the air is purged and replaced with a specific gas or mixture of gases. This seemingly simple difference is fundamental to modern manufacturing.

Preventing Oxidation and Decarburization

When metals are heated to high temperatures in the presence of oxygen, they oxidize—forming scale or rust on the surface. This is not just a cosmetic issue; it can compromise the material's structural integrity, dimensions, and performance.

Atmosphere furnaces prevent this by creating an inert atmosphere using gases like nitrogen or argon, or a reducing atmosphere with hydrogen. This protective blanket ensures the material is affected only by the heat, not by unwanted reactions with the air.

Ensuring Process Repeatability and Quality

In industrial-scale production, consistency is paramount. The thousandth part must be identical to the first. By eliminating the variable of atmospheric composition, these furnaces ensure that heat treatment processes are highly repeatable.

This level of control minimizes product defects, reduces scrap rates, and guarantees that every batch meets the required specifications. The result is higher product quality and greater overall efficiency.

Enabling Specific Material Transformations

Some advanced processes are not just protected by a specific atmosphere—they are enabled by it. The atmosphere itself becomes an active ingredient.

For example, carburizing involves heating steel in a carbon-rich atmosphere to harden its surface. In material synthesis, heating metal oxides in a specific atmosphere can create metal nanoparticles, or heating carbon materials can produce advanced structures like graphene.

Key Applications in Industrial Production

The ability to control the environment at high temperatures unlocks a range of critical industrial processes.

Heat Treatment of Metals

Processes like annealing (softening metal to improve ductility), hardening, and tempering all rely on precise heating and cooling cycles. Using an atmosphere furnace prevents surface defects and ensures the final component has the exact mechanical properties required, from aerospace parts to automotive gears.

Sintering of Powders

Sintering is the process of fusing fine particles together with heat to form a solid object. It is used to create parts from powdered metals, ceramics, and composites.

The high surface area of these powders makes them extremely vulnerable to oxidation. An atmosphere furnace is essential to protect the particles during heating, allowing them to bond correctly and form a strong, dense final part.

Brazing and Soldering

Brazing joins two pieces of metal using a filler metal that melts at a lower temperature. Performing this process in a controlled atmosphere prevents the formation of oxides on the parent metals, ensuring the filler flows cleanly and creates a strong, reliable joint without the need for corrosive fluxes.

Understanding the Trade-offs

While indispensable, atmosphere furnaces introduce operational considerations that differ from standard ovens.

Increased System Complexity

An atmosphere furnace is more than just a heating chamber. It requires a gas supply system, flow controllers, oxygen sensors, and robust seals to maintain the integrity of the internal environment. This adds to the initial capital cost and requires specialized knowledge for operation.

Gas Consumption and Costs

The controlled atmosphere is a consumable. The costs of nitrogen, argon, or hydrogen gas must be factored into the operational budget. Inefficient seals or improper operating procedures can lead to significant gas waste, increasing production costs.

Maintenance of Seals and Integrity

The furnace's effectiveness depends entirely on its ability to remain sealed. Door gaskets, thermocouples ports, and other access points are potential failure points. Regular inspection and maintenance are critical to prevent leaks that could compromise the atmosphere and the product.

Making the Right Choice for Your Goal

The decision to use an atmosphere furnace is directly tied to the level of material control you need to achieve.

- If your primary focus is achieving the highest material quality and batch-to-batch consistency: An atmosphere furnace is essential to eliminate oxidation and other process variables.

- If your primary focus is improving large-scale production efficiency: These furnaces reduce rework and scrap by preventing defects, often offsetting their higher operational cost in high-volume settings.

- If your primary focus is innovation and developing new materials: The precise environmental control is a prerequisite for creating advanced materials, alloys, and composites.

Ultimately, an atmosphere furnace gives you precise command over material chemistry at high temperatures—a capability that is fundamental to modern, high-performance manufacturing.

Summary Table:

| Role | Key Benefit | Industrial Application |

|---|---|---|

| Prevent Oxidation | Eliminates surface defects and maintains material integrity | Heat treatment of metals like annealing and hardening |

| Ensure Repeatability | Guarantees batch-to-batch consistency and reduces scrap | Sintering of powders for strong, dense parts |

| Enable Transformations | Allows specific chemical reactions for material synthesis | Brazing and soldering for reliable joints without fluxes |

Ready to elevate your industrial production with precision-controlled heating? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our atmosphere furnaces can enhance your quality, efficiency, and innovation!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing