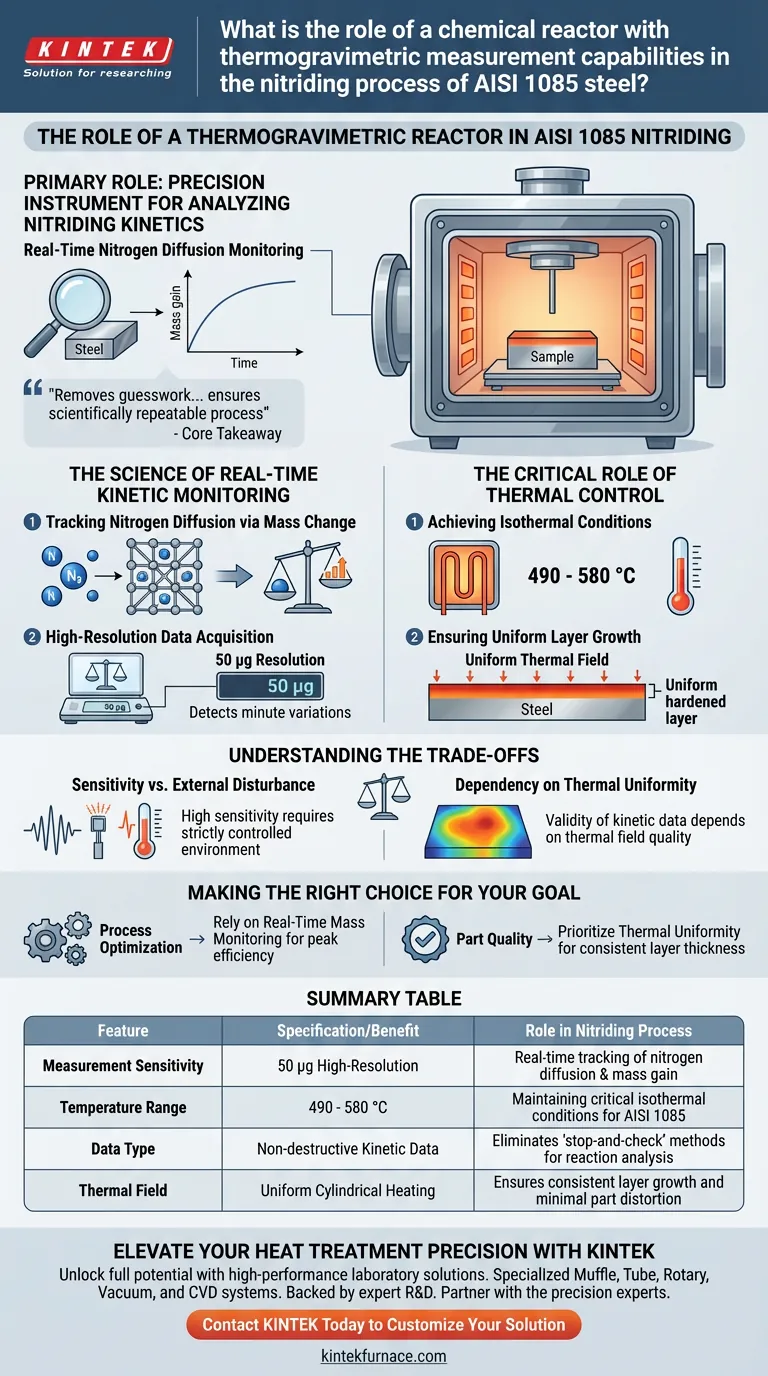

The primary role of a chemical reactor with thermogravimetric capabilities is to serve as a precision instrument for analyzing nitriding kinetics.

By utilizing a high-resolution mass measurement system, this equipment enables the real-time monitoring of nitrogen atom diffusion into AISI 1085 steel. This allows researchers and engineers to quantify the exact mass increase caused by the reaction without ever needing to interrupt the experimental process.

Core Takeaway: By correlating real-time mass gain (down to 50 µg) with process parameters, this technology removes the guesswork from nitriding. It provides the data necessary to determine precise growth patterns and reaction efficiencies, ensuring the surface hardening process is scientifically repeatable rather than just empirically observed.

The Science of Real-Time Kinetic Monitoring

Tracking Nitrogen Diffusion via Mass Change

The fundamental principle of this reactor is the correlation between mass and chemical composition. As nitrogen atoms diffuse into the surface of AISI 1085 steel, the sample becomes physically heavier.

This reactor continuously weighs the sample during the treatment. This offers a direct, non-destructive window into the reaction's progress, replacing the need for "stop-and-check" methods.

High-Resolution Data Acquisition

Accuracy is paramount when studying atomic diffusion. The reactor features a measurement system capable of detecting mass changes with a resolution of 50 µg.

This extreme sensitivity allows for the detection of minute variations in the nitriding layer's growth. It provides the granular data needed to build accurate models of how the steel reacts under specific conditions.

The Critical Role of Thermal Control

Achieving Isothermal Conditions

While the thermogravimetric balance measures the "what," the reaction chamber controls the "how." The system utilizes an electrically heated cylindrical chamber to maintain a precise thermal environment.

This setup ensures the process remains strictly isothermal. For AISI 1085 steel, this is typically maintained within a critical temperature range of 490 to 580 °C.

Ensuring Uniform Layer Growth

Mass data is only reliable if the reaction is consistent across the entire sample. The reactor’s temperature control system provides an extremely uniform thermal field.

This uniformity ensures that nitrogen diffusion rates are consistent across the sample's surface. The result is a hardened layer with uniform thickness and minimal distortion, validating the mass change data collected by the sensor.

Understanding the Trade-offs

Sensitivity vs. External Disturbance

The high precision of the thermogravimetric system (50 µg) is its greatest strength, but also a potential vulnerability.

Such high sensitivity requires a strictly controlled environment. Any fluctuation in the thermal field or mechanical stability can introduce noise into the data, potentially obscuring the true kinetic readings.

The Dependency on Thermal Uniformity

The validity of the kinetic data is entirely dependent on the quality of the thermal field.

If the reaction chamber fails to provide uniform heat, the nitrogen diffusion rates will vary across the sample. This would render the aggregate mass measurement inaccurate as a representation of layer growth, leading to flawed conclusions about reaction efficiency.

Making the Right Choice for Your Goal

Whether you are conducting fundamental research or optimizing an industrial recipe, understanding the specific capabilities of this reactor is essential.

- If your primary focus is Process Optimization: rely on the real-time mass monitoring to determine the exact moment the reaction efficiency peaks, preventing wasted time and resources.

- If your primary focus is Part Quality: prioritize the thermal uniformity of the chamber to ensure consistent layer thickness and minimal distortion across the AISI 1085 steel surface.

Ultimately, this technology bridges the gap between theoretical kinetics and practical application, providing the visibility needed to master the nitriding process.

Summary Table:

| Feature | Specification/Benefit | Role in Nitriding Process |

|---|---|---|

| Measurement Sensitivity | 50 µg High-Resolution | Real-time tracking of nitrogen diffusion & mass gain |

| Temperature Range | 490 - 580 °C | Maintaining critical isothermal conditions for AISI 1085 |

| Data Type | Non-destructive Kinetic Data | Eliminates 'stop-and-check' methods for reaction analysis |

| Thermal Field | Uniform Cylindrical Heating | Ensures consistent layer growth and minimal part distortion |

Elevate Your Heat Treatment Precision with KINTEK

Unlock the full potential of your nitriding processes with high-performance laboratory solutions from KINTEK. Backed by expert R&D and world-class manufacturing, we provide specialized Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your exact thermal and kinetic research needs.

Whether you require extreme thermal uniformity for AISI 1085 steel or customizable high-temperature furnaces for complex chemical reactions, KINTEK delivers the reliability and accuracy your lab demands. Don't leave your results to guesswork—partner with the precision experts.

Contact KINTEK Today to Customize Your Solution

Visual Guide

References

- T. Frączek, M. Ogórek. The Influence of Selected Process Parameters on the Efficiency of the Process of Gas Nitriding of AISI 1085 Steel. DOI: 10.3390/ma17112600

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why are inert atmosphere furnaces important for graphite and carbon products? Prevent Oxidation and Ensure High-Performance Results

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance