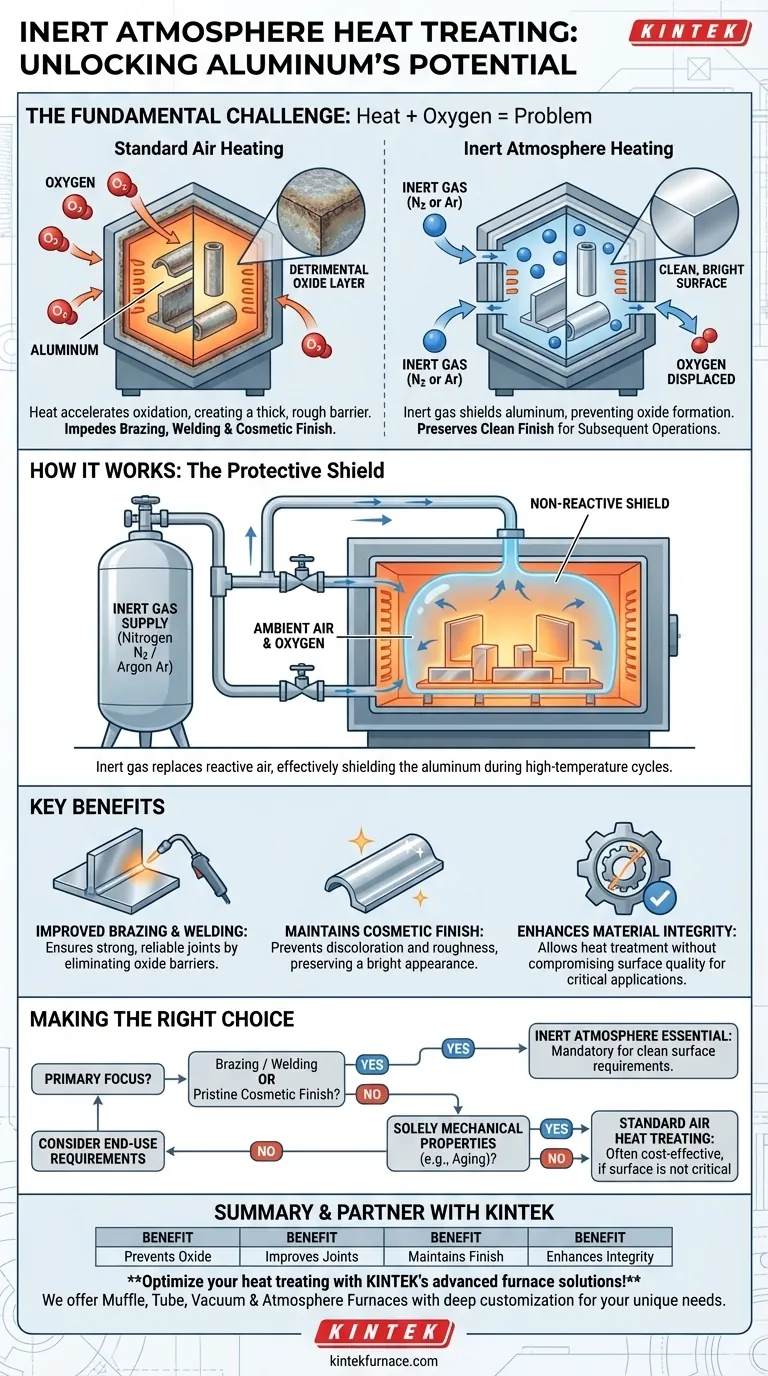

At its core, inert atmosphere heat treating benefits aluminum by preventing the formation of a thick, detrimental oxide layer on its surface. By replacing reactive air with a neutral gas like nitrogen or argon, the process preserves the material's clean finish and ensures it remains suitable for critical subsequent operations like brazing and welding.

The fundamental challenge with heat treating aluminum is that the very heat needed to alter its mechanical properties also accelerates its reaction with oxygen. An inert atmosphere shields the aluminum, allowing the heat to do its work without compromising the integrity and quality of the material's surface.

The Fundamental Challenge: Aluminum and Oxygen

Heat treating aluminum in ambient air creates a conflict. The goal is to improve the metal's internal structure, but the process can inadvertently damage its external surface.

The Protective-Turned-Problematic Oxide Layer

At room temperature, aluminum naturally forms a very thin, tough, and transparent layer of aluminum oxide. This layer is actually beneficial, as it passivates the surface and protects the metal from corrosion.

The Destructive Impact of Heat

When heated to the temperatures required for processes like annealing, solution treating, or aging, the rate of oxidation increases dramatically. This once-thin, protective layer rapidly grows into a thick, rough, and discolored coating.

Why a Thick Oxide Layer is Detrimental

This uncontrolled oxide growth is a significant problem for high-performance applications. It acts as a barrier that can impede subsequent manufacturing steps and compromise the final component's quality.

Specifically, it prevents the proper flow and adhesion of filler metals during brazing and welding, leading to weak or failed joints. It also creates a poor cosmetic finish and can even affect the final dimensions of precision parts.

How Inert Atmospheres Provide the Solution

The principle behind inert atmosphere heat treating is to remove the reactant—oxygen—from the environment.

The Principle of Displacement

In this process, the furnace chamber is purged of normal air and filled with an inert, or non-reactive, gas. This gas displaces the oxygen, creating a neutral environment.

Creating a Non-Reactive Shield

With no oxygen present to react with the hot aluminum, the destructive oxide layer cannot form. The aluminum surface is effectively shielded, remaining clean and bright throughout the high-temperature cycle.

Common Gases Used

The most common gas for this purpose is nitrogen, which is highly effective and relatively inexpensive. For extremely sensitive applications where even trace reactions with nitrogen are a concern, argon is used, though it comes at a higher cost.

Understanding the Trade-offs and Considerations

While highly effective, inert atmosphere heat treating is not a universal solution. The decision to use it involves balancing technical requirements with economic realities.

Cost vs. Benefit

The primary trade-off is cost. Inert atmosphere furnaces are more complex, and the continuous consumption of high-purity nitrogen or argon adds a significant operational expense compared to treating in an open-air furnace.

Gas Purity is Critical

The effectiveness of the process depends entirely on the purity of the inert atmosphere. Any leaks that allow air to enter the furnace or the use of a low-purity gas can compromise the results and negate the benefit.

When It May Not Be Necessary

For applications where surface finish is not a cosmetic or functional requirement, and no post-treatment brazing or welding is planned, standard air-atmosphere treatment is often sufficient. If the sole purpose is to alter bulk mechanical properties, the added expense of an inert atmosphere may not be justified.

Making the Right Choice for Your Application

Deciding whether to specify an inert atmosphere depends entirely on the end-use requirements of the aluminum component.

- If your primary focus is brazing or welding: Inert atmosphere treatment is essentially mandatory to ensure a clean, oxide-free surface for a strong, reliable joint.

- If your primary focus is a pristine cosmetic finish: Using an inert atmosphere is the most reliable way to prevent heat-induced discoloration and maintain a bright, clean surface.

- If your primary focus is solely on mechanical properties (e.g., aging) with no critical surface requirements: Standard heat treating in air may be the more cost-effective solution.

By understanding the role of the furnace atmosphere, you can control the outcome of your heat treatment to ensure the final component meets all of its specifications.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxide Formation | Shields aluminum from oxygen, avoiding thick, detrimental oxide layers during heating. |

| Improves Brazing/Welding | Ensures clean surfaces for strong, reliable joints by eliminating oxide barriers. |

| Maintains Cosmetic Finish | Preserves bright, clean appearance by preventing discoloration and roughness. |

| Enhances Material Integrity | Allows heat treatment without compromising surface quality for critical applications. |

Optimize your aluminum heat treating with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, helping you achieve superior results in brazing, welding, and material integrity. Contact us today to discuss how we can enhance your processes!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality