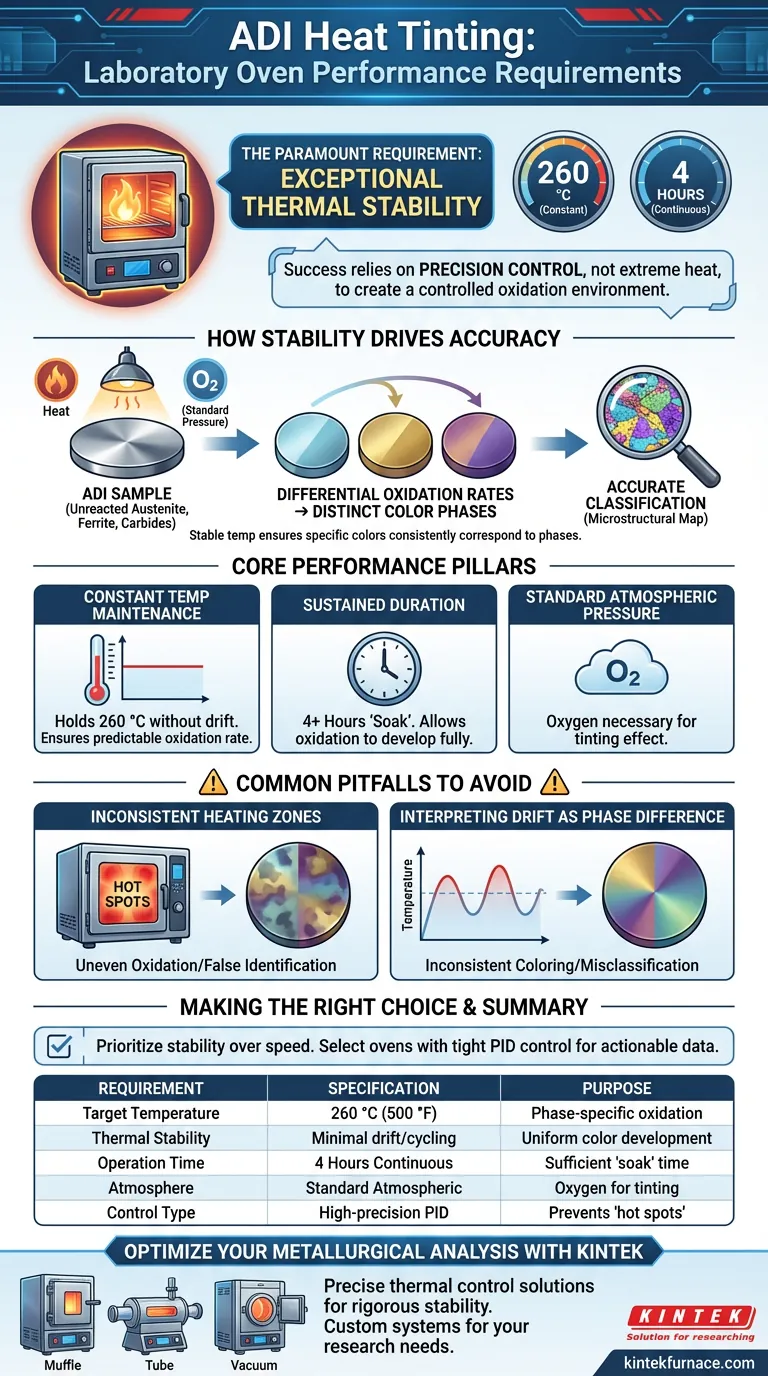

The paramount requirement for a laboratory oven used in heat tinting Austempered Ductile Iron (ADI) is exceptional thermal stability. To ensure accurate analysis, the unit must be capable of maintaining a constant temperature of 260 °C for a continuous duration of 4 hours under standard atmospheric pressure.

Success in heat tinting ADI relies on precision temperature control rather than extreme heat. The oven’s primary function is to create a controlled oxidation environment that reveals distinct microstructural phases through color differentiation.

The Mechanics of Thermal Stability

Constant Temperature Maintenance

The tinting process is highly sensitive to thermal fluctuations. The oven must hold 260 °C steadily without significant drift or cycling.

This stability ensures that the oxidation process proceeds at a predictable rate across the entire sample surface.

Sustained Duration

The equipment must be rated for continuous operation at the target temperature for at least 4 hours.

This is not a rapid heat-treatment cycle; it is a sustained "soak" that allows the oxidation to develop fully and evenly.

Standard Atmospheric Pressure

Unlike vacuum or inert gas furnaces, this process requires standard atmospheric pressure.

The presence of oxygen is necessary to facilitate the oxidation that creates the tinting effect on the metal's surface.

Why Stability Drives Analytical Accuracy

Differential Oxidation Rates

The core purpose of this oven is to exploit the varying oxidation stabilities of different microstructural phases.

Components such as unreacted austenite, ferrite, and carbides oxidize at different speeds when exposed to heat.

Creating Characteristic Colors

Because these phases oxidize differently, they develop distinct colors when held at a stable high temperature.

This color contrast allows technicians to visually separate and identify complex mixed phases that would otherwise be difficult to distinguish.

Accurate Classification

If the oven temperature fluctuates, the oxidation rates change, leading to inconsistent coloring.

A stable environment ensures that specific colors consistently correspond to specific phases, allowing for reliable classification of the ADI microstructure.

Common Pitfalls to Avoid

Inconsistent Heating Zones

If the oven has "hot spots" or uneven heating, the sample will oxidize unevenly.

This can result in a single phase appearing as two different colors, leading to false identification of the microstructure.

Interpreting Drift as Phase Difference

An oven that cannot hold 260 °C precisely may produce colors that do not align with standard references.

This forces the technician to guess whether a color shift is due to the material composition or an equipment fault.

Making the Right Choice for Your Goal

To ensure your heat tinting process yields actionable data, prioritize stability over speed.

- If your primary focus is Equipment Selection: Choose a laboratory oven with tight PID temperature control verified to hold 260 °C without oscillation.

- If your primary focus is Process Accuracy: Verify that the oven operates at standard atmospheric pressure to ensure sufficient oxygen availability for oxidation.

Precise thermal control is the only way to transform raw metal samples into readable microstructural maps.

Summary Table:

| Requirement | Specification | Purpose in ADI Analysis |

|---|---|---|

| Target Temperature | 260 °C (500 °F) | Optimal temperature for phase-specific oxidation |

| Thermal Stability | Minimal drift/cycling | Ensures uniform color development across samples |

| Operation Time | 4 Hours Continuous | Allows sufficient 'soak' time for full oxidation |

| Atmosphere | Standard Atmospheric | Provides oxygen needed to create the tinting effect |

| Control Type | High-precision PID | Prevents 'hot spots' and false color identification |

Optimize Your Metallurgical Analysis with KINTEK

Precise microstructural identification starts with superior thermal control. KINTEK provides high-performance laboratory ovens and high-temperature furnaces engineered for the rigorous stability required in ADI heat tinting.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your laboratory's unique research needs. Ensure your analytical accuracy and eliminate equipment-induced variables today.

Ready to upgrade your lab's precision? Contact KINTEK experts now to find your custom solution.

Visual Guide

References

- P. Lachart, Rainer Masendorf. Prediction of Cross-Section-Dependent ADI Microstructures by Experimental Heat Treatment Simulation. DOI: 10.1007/s40962-023-01246-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is temperature and atmosphere monitoring critical in furnace operations? Ensure Safety and Quality in Heat Treatment

- What types of heat treatment processes require controlled atmospheres? Essential for Surface Protection and Modification

- What is the role of an Argon gas environment in sintering Boron Carbide? Achieve High Density and Prevent Oxidation

- Why is it important to isolate the working space in an atmosphere furnace from outside air? Ensure Process Control and Safety

- What are the different configurations available for inert atmosphere furnaces? Find Your Perfect Match for Heat Treatment

- Why Use a Nitrogen Debinding Furnace for 17-4PH? Ensure Pure Metal Bonds & Prevent Oxidation

- Why are vacuum or atmosphere control systems required for Fe, Co, and Ni single-atom catalysts? Ensure Atomic Precision

- What are the operational considerations for atmosphere furnaces? Master Precise Control for Safe, Efficient Results