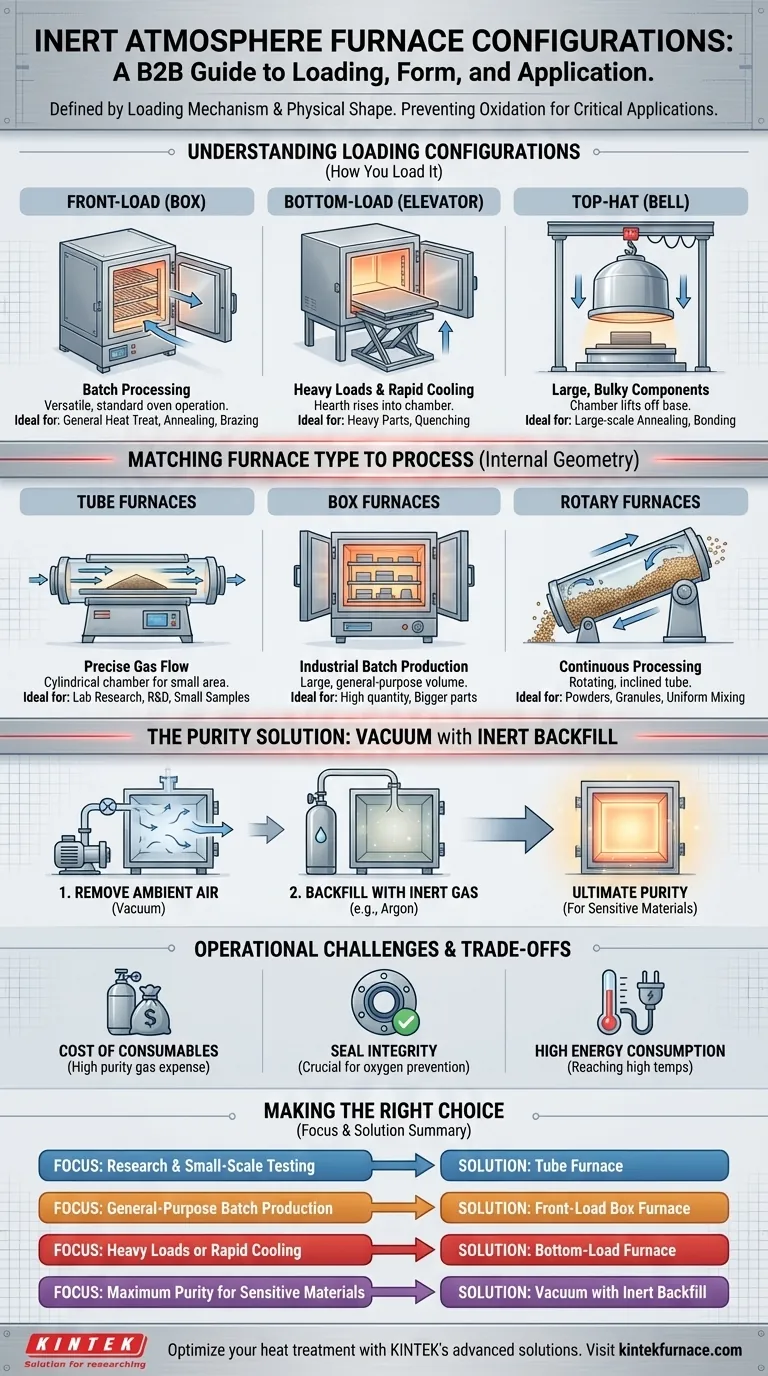

In short, inert atmosphere furnaces are primarily defined by their loading mechanism and their physical shape. The main loading configurations are front-load, bottom-load, and top-hat, while the most common types based on their form factor are box, tube, and rotary furnaces. These designs are engineered to support specific applications, from lab-scale research to mass production, where preventing oxidation with a controlled gas like nitrogen or argon is critical.

The optimal furnace configuration is not a matter of finding the "best" one, but of precisely matching the furnace's design to the size of your material, your production volume, and the specific demands of your heat treatment process.

Understanding Loading Configurations

The way you load and unload materials from the furnace is a primary design consideration. This choice impacts workflow, the types of materials you can process, and even process capabilities like cooling rates.

Front-Load (Box) Furnaces

This is the most conventional design, operating much like a standard oven with a door on the front. It is a versatile, all-purpose configuration.

Front-load furnaces are ideal for batch processing of various parts on shelves or trays. They are straightforward to operate and are a common choice for general heat treatment, annealing, and brazing.

Bottom-Load Furnaces

In this design, the hearth (the furnace floor) is raised into the stationary heating chamber from below, often using an elevator mechanism.

This configuration is exceptionally well-suited for processing very heavy loads. It also allows for rapid cooling (quenching) by quickly lowering the material out of the hot zone, which is critical for certain metallurgical processes.

Top-Hat (Bell) Furnaces

With a top-hat or "bell" furnace, the heating chamber is lowered over a stationary base where the material is placed. The furnace body is lifted off for loading and unloading.

This design is perfect for large, bulky, or awkwardly shaped components that cannot be easily loaded into a chamber. It provides excellent access and is often used for large-scale annealing or bonding applications.

Matching Furnace Type to Your Process

Beyond how you load it, the internal geometry of the furnace dictates how heat and atmosphere are applied to your material.

Tube Furnaces

Tube furnaces use a cylindrical chamber, typically made of ceramic or quartz, to heat a smaller, well-defined area.

They are the standard for laboratory research, R&D, and processing small samples. The tubular design provides excellent atmospheric control and is ideal for processes that benefit from precise gas flow over the material.

Box Furnaces

A box furnace, which typically uses a front-load door, is a rectangular chamber designed for general-purpose work.

This is the workhorse for industrial batch production. Its larger volume can accommodate bigger individual parts or a high quantity of smaller parts arranged on racks.

Rotary Furnaces

These furnaces feature a rotating cylindrical tube that is slightly inclined, causing material to tumble and move through the heat zone.

Rotary furnaces are designed for continuous processing of powders, granules, or small parts that require constant mixing to ensure every surface is uniformly heated and exposed to the inert atmosphere.

The Special Case: Vacuum with Inert Backfill

For applications demanding the highest possible purity, the process involves more than simply purging the chamber with inert gas.

Why Start with a Vacuum?

The most effective method for creating a pure inert atmosphere is to first use a vacuum pump to remove the ambient air, which contains oxygen and moisture.

Achieving Ultimate Purity

After pulling a vacuum, the chamber is backfilled with high-purity inert gas. For highly sensitive materials, this pump-down and backfill cycle can be repeated several times to dilute any remaining contaminants to negligible levels, ensuring the integrity of materials that react to even trace amounts of oxygen.

Understanding the Trade-offs and Challenges

While essential, operating an inert atmosphere furnace involves specific operational considerations and costs that must be managed.

Cost of Consumables

High-purity inert gases, particularly argon, can be a significant operational expense. Efficient furnace operation and a leak-free system are crucial to minimizing gas consumption.

Maintaining Seal Integrity

The entire system—including doors, ports, and gas lines—must be perfectly sealed to prevent oxygen from leaking into the chamber at high temperatures. Regular maintenance and seal inspection are non-negotiable.

High Energy Consumption

Reaching and holding the high temperatures required for processes like brazing or annealing consumes a substantial amount of energy. Proper insulation and efficient heating elements are key to managing these costs.

Making the Right Choice for Your Goal

Selecting the correct furnace configuration requires aligning the design with your primary objective.

- If your primary focus is research and small-scale testing: A tube furnace offers the best control and atmospheric purity for small, well-defined samples.

- If your primary focus is general-purpose batch production: A front-load box furnace provides the most versatility for a wide range of part sizes and applications.

- If your primary focus is processing heavy loads or requiring rapid cooling: A bottom-load furnace is specifically designed for these demanding mechanical and thermal requirements.

- If your primary focus is maximum purity for sensitive materials: A vacuum furnace with an inert gas backfill system is the only way to reliably remove atmospheric contaminants.

By aligning the furnace's design with your specific material and process goals, you ensure both operational efficiency and final product integrity.

Summary Table:

| Configuration Type | Key Features | Ideal Applications |

|---|---|---|

| Front-Load (Box) | Versatile, batch processing, easy operation | General heat treatment, annealing, brazing |

| Bottom-Load | Handles heavy loads, rapid cooling | Metallurgical quenching, heavy part processing |

| Top-Hat (Bell) | Excellent access for large components | Large-scale annealing, bonding |

| Tube | Cylindrical chamber, precise gas flow | Laboratory research, R&D, small samples |

| Rotary | Continuous processing, uniform mixing | Powders, granules, small parts |

| Vacuum with Inert Backfill | High purity, removes contaminants | Sensitive materials requiring ultimate purity |

Ready to optimize your heat treatment process with the right inert atmosphere furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and product integrity!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage