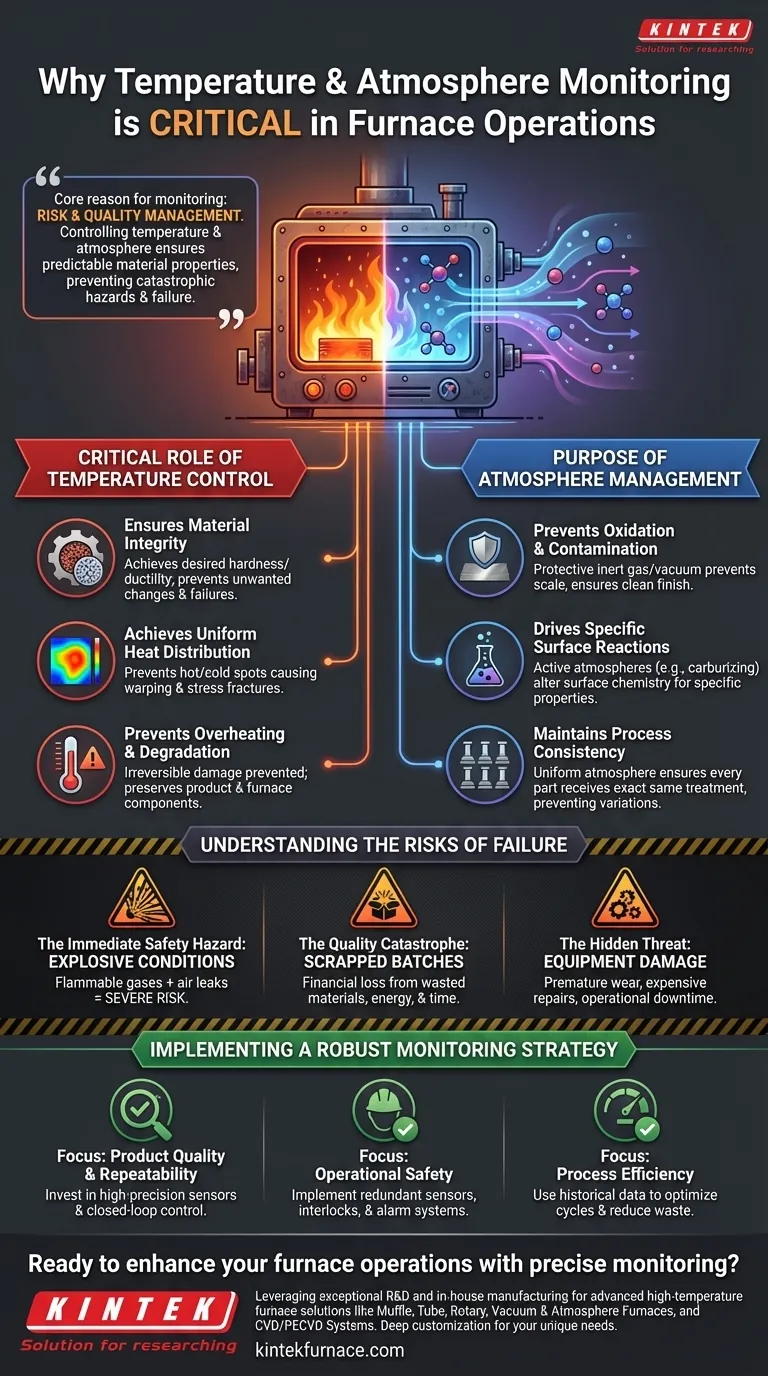

In furnace operations, the continuous monitoring of temperature and atmosphere is not merely a best practice; it is fundamental to safety, quality, and operational efficiency. This constant vigilance allows operators to detect and correct abnormalities immediately, preventing catastrophic failures such as explosive gas mixtures, uneven heating, or material degradation. This ensures both a safe working environment and the consistent, high-quality results demanded by modern heat treatment processes.

The core reason for monitoring is risk and quality management. Temperature and atmosphere are the two most powerful variables in heat treatment; controlling them ensures predictable material properties, while failing to do so invites catastrophic safety hazards and product failure.

The Critical Role of Temperature Control

Precise temperature control is the foundation of any successful heat treatment process. Even minor deviations can have significant and costly consequences for the final product.

Ensuring Material Integrity

The primary goal of heat treatment is to alter a material's microstructure to achieve desired properties like hardness or ductility. Temperature stability is paramount, as even small fluctuations can cause unwanted changes, leading to inconsistent or failed parts. Repeatability is only possible with unwavering temperature control.

Achieving Uniform Heat Distribution

The furnace atmosphere itself acts as a thermal conductor. Proper control ensures this gaseous medium distributes heat evenly throughout the chamber. This prevents hot or cold spots that can cause warping, stress fractures, or non-uniform material properties across a single batch.

Preventing Overheating and Degradation

Exceeding the target temperature can irreversibly damage or degrade materials. Precise monitoring, coupled with safety limits and alarms, prevents overheating, preserving the integrity of the product and protecting the furnace's internal components from damage.

The Purpose of Atmosphere Management

The gaseous environment within a furnace is an active component of the process. It can be protective, reactive, or simply a medium for heat transfer, and its composition must be carefully managed.

Preventing Oxidation and Contamination

The most common role of a furnace atmosphere is to be protective. By displacing oxygen with an inert gas like nitrogen or creating a vacuum, it prevents the formation of scale and oxides on the material's surface, ensuring a clean finish and preserving part dimensions.

Driving Specific Surface Reactions

Atmospheres can also be active, deliberately introducing elements to alter a material's surface. Processes like carburizing use a carbon-rich atmosphere to harden the surface of steel. The precise concentration of gases is critical to achieving the specified surface chemistry.

Maintaining Process Consistency

A uniform atmosphere is essential for ensuring every part within the furnace receives the exact same treatment. Inconsistent gas flow or composition can lead to localized issues, such as uneven carbon concentration, resulting in a batch of products with unacceptable variations.

Understanding the Risks of Failure

A failure to monitor and control these variables is not a minor operational issue; it is a direct path to significant safety and financial risk.

The Immediate Safety Hazard: Explosive Conditions

Many controlled atmospheres use flammable or combustible gases like hydrogen. If the gas mixture is not precisely maintained or if air (oxygen) is allowed to leak into the furnace, an explosive environment can be created, posing a severe risk to personnel and equipment.

The Quality Catastrophe: Scrapped Batches

A deviation in either temperature or atmosphere can ruin an entire production batch. The financial loss from scrapped materials, wasted energy, and lost production time can be immense. Without monitoring, the cause of the failure can be difficult to diagnose, leading to repeated problems.

The Hidden Threat: Equipment Damage

Uncontrolled atmospheric reactions or extreme temperature cycles can cause premature wear and damage to the furnace's internal components, such as heating elements and insulation. This leads to expensive, unplanned maintenance and significant operational downtime.

Implementing a Robust Monitoring Strategy

Your approach to monitoring should be directly aligned with your primary operational goals. Implementing a robust strategy involves more than just installing sensors; it requires a clear understanding of your priorities.

- If your primary focus is product quality and repeatability: Invest in high-precision sensors and closed-loop control systems to minimize temperature and atmospheric fluctuations.

- If your primary focus is operational safety: Implement redundant sensors, automatic interlocks, and clear alarm systems to immediately detect and mitigate hazardous conditions.

- If your primary focus is process efficiency: Use historical monitoring data to optimize cycle times, gas consumption, and energy usage, reducing waste without compromising results.

Ultimately, treating temperature and atmosphere data as a critical asset empowers you to transform furnace operations from a variable art into a predictable science.

Summary Table:

| Aspect | Key Points |

|---|---|

| Temperature Control | Ensures material integrity, uniform heating, prevents overheating and degradation |

| Atmosphere Management | Prevents oxidation, drives surface reactions, maintains process consistency |

| Risks of Failure | Explosive conditions, scrapped batches, equipment damage |

| Monitoring Strategy | Focus on quality, safety, or efficiency with tailored sensors and systems |

Ready to enhance your furnace operations with precise monitoring? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior safety, quality, and efficiency. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas