Isolating the working space of an atmosphere furnace is an absolute necessity for controlling the metallurgical process and ensuring operational safety. Without a perfect seal from the outside air, you lose control over the chemical reactions happening at high temperatures, leading to damaged products and creating significant safety hazards.

The core challenge is not merely keeping air out; it is about creating and maintaining a highly specific, artificial chemical environment. Failure to isolate the furnace renders the entire heat treatment process unpredictable, inefficient, and dangerous.

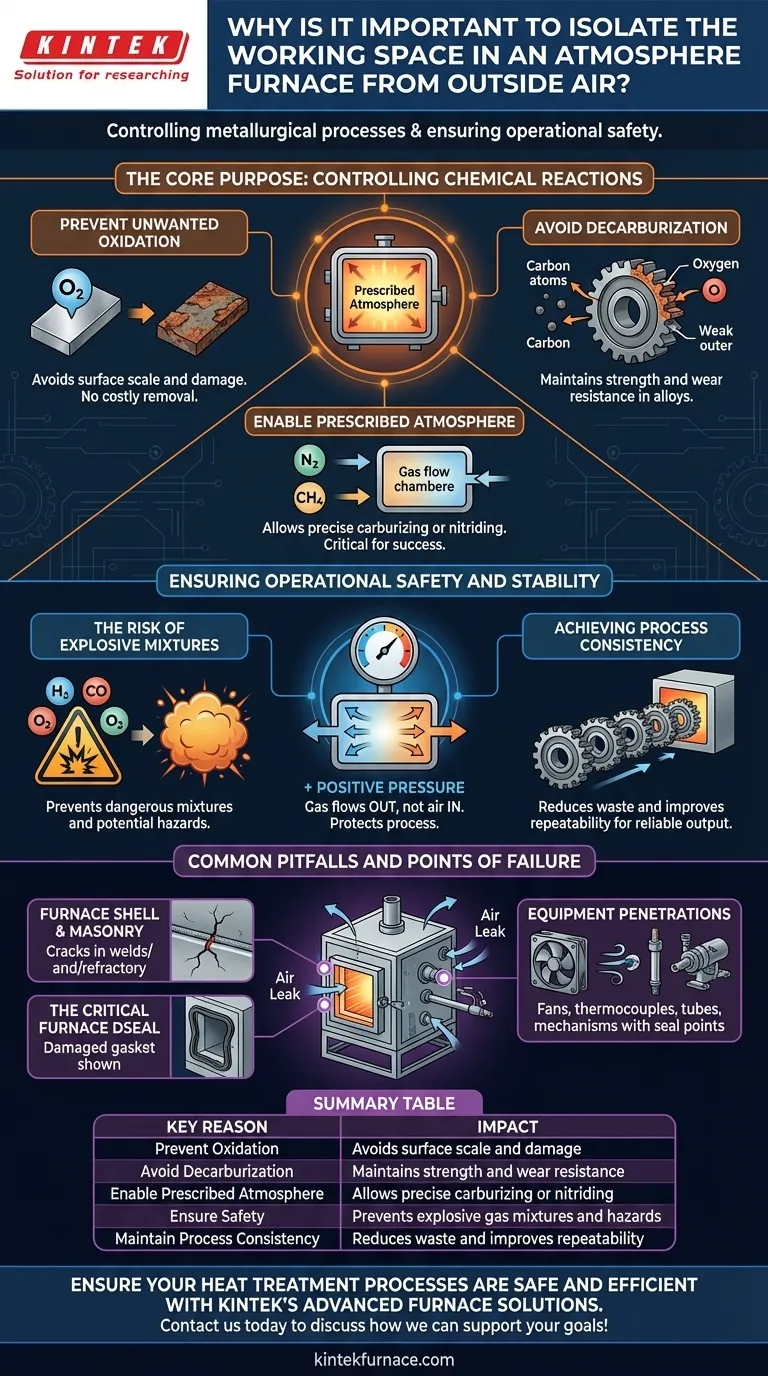

The Core Purpose: Controlling Chemical Reactions

An atmosphere furnace is, at its heart, a chemical reactor. The isolation of its chamber is fundamental to controlling the reactions that determine a material's final properties.

Preventing Unwanted Oxidation

When hot metal is exposed to oxygen from the air, it rapidly oxidizes, forming a layer of scale on the surface. This scale can ruin the surface finish, alter component dimensions, and must be removed in a costly secondary process. A sealed furnace prevents this by eliminating the source of oxygen.

Avoiding Decarburization

For carbon-based alloys like steel, oxygen ingress has another destructive effect: decarburization. Oxygen atoms react with and remove carbon from the surface of the steel, creating a soft, weak outer layer that compromises the part's strength and wear resistance.

Enabling a Prescribed Atmosphere

Many processes, such as carburizing or nitriding, require a specific atmosphere gas (e.g., endothermic gas, ammonia) to be introduced. This gas is engineered to donate elements like carbon or nitrogen to the workpiece. Any air leaking into the furnace contaminates and dilutes this carefully balanced gas, causing the entire metallurgical process to fail.

Ensuring Operational Safety and Stability

Beyond product quality, proper sealing is a non-negotiable requirement for safe and consistent furnace operation.

The Risk of Explosive Mixtures

Many protective atmospheres contain high concentrations of flammable gases like hydrogen and carbon monoxide. If outside air leaks into the furnace, the oxygen can mix with these gases, creating a potentially explosive mixture. A catastrophic explosion can occur if this mixture finds an ignition source.

Maintaining Positive Furnace Pressure

Airtight construction allows the furnace to maintain a slight positive pressure. This is a critical operational principle where the internal pressure is kept just above the external atmospheric pressure. As a result, if a minor leak does exist, the controlled atmosphere gas flows out rather than air flowing in, protecting the work and the process.

Achieving Process Consistency

Even small, intermittent air leaks create a constantly changing internal atmosphere. This variability makes it impossible to achieve repeatable results. One batch may be perfect, while the next is scrapped, leading to significant waste and unreliable production output.

Common Pitfalls and Points of Failure

Achieving and maintaining isolation requires constant vigilance, as several points are prone to developing leaks over time.

Furnace Shell and Masonry

Cracks in the furnace shell welds or degradation of the refractory masonry can create pathways for air to enter. Over time, thermal cycling can stress these components, making regular inspection essential.

The Critical Furnace Door Seal

The furnace door is opened and closed frequently, and its seal is subject to constant wear and tear. A damaged or compressed gasket is one of the most common sources of contamination and must be regularly inspected and replaced.

Equipment Penetrations

Every component that passes through the furnace wall is a potential leak point. This includes fans, thermocouples, radiant tubes, and mechanical pusher/puller mechanisms. Each of these penetrations must have a robust sealing device that can withstand high temperatures and pressure differentials.

Making the Right Choice for Your Goal

Ensuring furnace integrity is the foundation of any controlled thermal process. Your priorities will determine where you focus your efforts.

- If your primary focus is product quality: Your top priority is monitoring oxygen levels and ensuring a stable, positive pressure to prevent oxidation and decarburization.

- If your primary focus is operational safety: You must implement strict procedures for purging the furnace with an inert gas before introducing flammable atmospheres and ensure all safety interlocks are functioning.

- If your primary focus is process efficiency: Regular leak detection tests are non-negotiable, as they prevent wasted protective gas and reduce the cost of rework for failed batches.

Ultimately, a well-sealed furnace is the only tool that gives you absolute control over your heat treatment outcomes.

Summary Table:

| Key Reason | Impact |

|---|---|

| Prevent Oxidation | Avoids surface scale and damage to materials |

| Avoid Decarburization | Maintains strength and wear resistance in alloys |

| Enable Prescribed Atmosphere | Allows precise carburizing or nitriding |

| Ensure Safety | Prevents explosive gas mixtures and hazards |

| Maintain Process Consistency | Reduces waste and improves repeatability |

Ensure your heat treatment processes are safe and efficient with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability tailors each solution to your unique experimental needs, helping you achieve precise control and superior results. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments