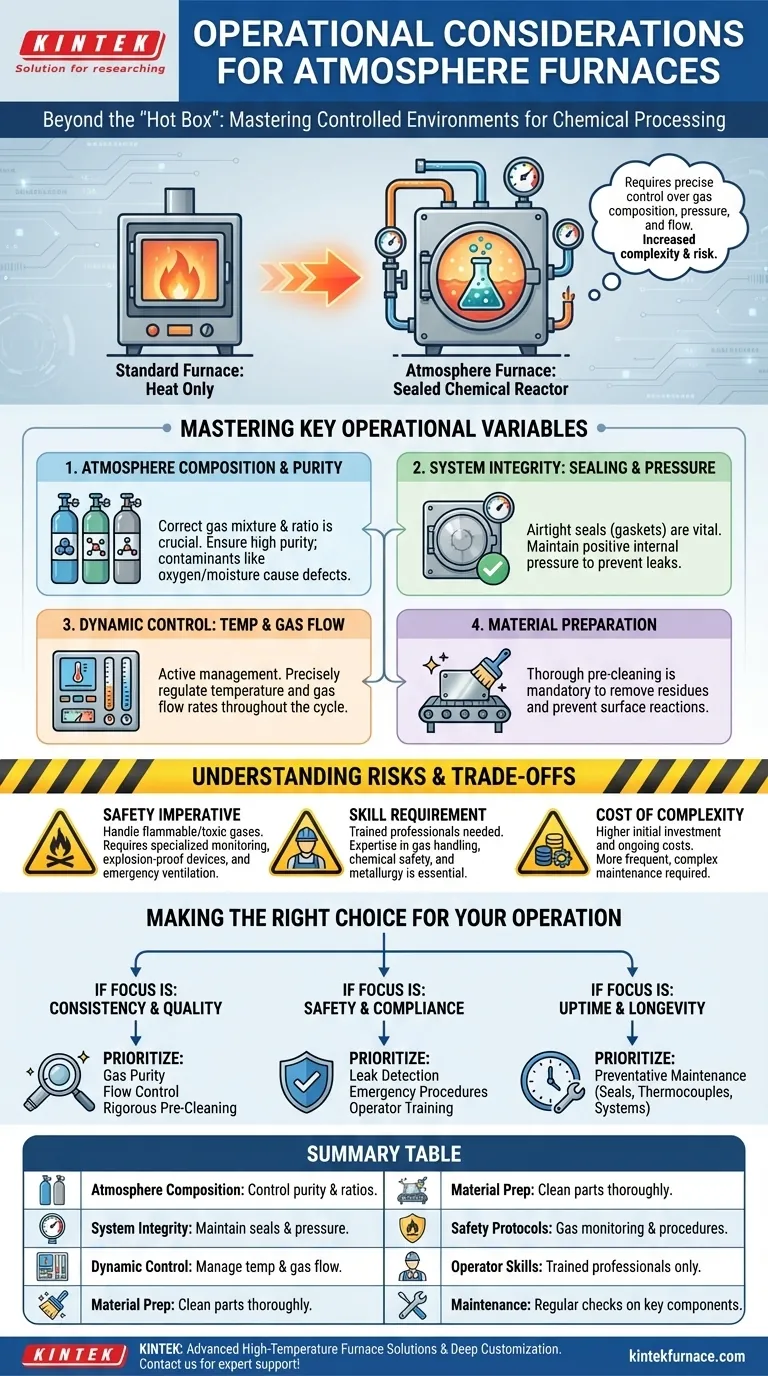

Operating an atmosphere furnace successfully requires a fundamentally different mindset than operating a standard furnace. It demands rigorous control over not just temperature, but also the chemical environment within the chamber. Key considerations involve maintaining precise atmospheric composition and purity, ensuring the furnace's seal integrity, implementing strict safety protocols for handling potentially hazardous gases, and conducting regular, specialized maintenance.

Unlike a standard furnace that only controls heat, an atmosphere furnace is a sealed chemical processing environment. Your success and safety depend entirely on precise control over the gas composition, pressure, and flow, which introduces significant operational complexity and risk.

The Core Challenge: From Heating to Chemical Processing

The purpose of an atmosphere furnace is to use a controlled gas environment to intentionally alter the surface chemistry of a material. This is done for processes like carburizing, bright annealing, or normalizing.

This transforms the furnace from a simple "hot box" into a contained chemical reactor. Every operational decision must be viewed through this lens.

Mastering the Key Operational Variables

Effective operation is a matter of managing several interconnected variables. A failure in one area will compromise the entire process and can create significant safety hazards.

Atmosphere Composition and Purity

The specific gas mixture—the "atmosphere"—is the primary active ingredient in your process. Even minor deviations can ruin a batch.

You must ensure the correct gases are used at the correct mixture ratios. Equally important is the purity of the source gas, as contaminants like oxygen or moisture can cause unwanted oxidation and product defects.

System Integrity: Sealing and Pressure

An atmosphere furnace is only effective if it is perfectly sealed. The goal is to keep the controlled atmosphere in and the external air out.

Sealing mechanisms, such as door gaskets and flange seals, must be inspected and maintained relentlessly. A positive internal pressure is often maintained to help prevent air from leaking into the chamber, making continuous pressure monitoring a critical operational task.

Dynamic Control: Temperature and Gas Flow

Operating an atmosphere furnace is not a "set and forget" process. It requires active management throughout the cycle.

Temperature control systems, including thermocouples, must provide accurate readings to the controller. Likewise, the atmosphere control system must precisely manage the flow rates of different gases entering the furnace to maintain the desired composition as the process evolves.

Material Preparation

The parts being treated are part of the chemical equation. Any contaminants on their surface can and will react with the hot furnace atmosphere.

Thorough cleaning to remove oils, grease, or other residues is not optional. It is a mandatory step to prevent surface blemishes, inconsistent results, and contamination of the furnace interior.

Understanding the Inherent Risks and Trade-offs

The capabilities of an atmosphere furnace come with significant responsibilities and costs that are not present with simpler equipment.

The Safety Imperative

This is the most critical distinction. Many furnace atmospheres use flammable or explosive gases like hydrogen and ammonia, or produce toxic byproducts like carbon monoxide.

Unlike a simple box furnace, this necessitates specialized gas monitoring systems, explosion-proof devices, and robust emergency ventilation. The safety threshold is dramatically higher.

The Skill Requirement

Because of the inherent dangers and process sensitivity, these furnaces cannot be run by untrained staff.

Professional operators are required. They must be trained not only in high-temperature equipment operation but also in the principles of gas handling, chemical safety, and the specific metallurgical process being performed.

The Cost of Complexity

The need for advanced control systems, gas purification, safety monitoring, and robust sealing mechanisms increases both the initial capital investment and ongoing operational costs. Maintenance is more frequent, more complex, and requires a higher level of technical skill.

Making the Right Choice for Your Operation

Your daily operational focus should align directly with your most critical outcomes.

- If your primary focus is process consistency and quality: Your priority must be gas purity, precise flow control, and rigorous pre-cleaning of all materials.

- If your primary focus is operator safety and compliance: You must prioritize robust leak detection, documented emergency procedures, and comprehensive operator training on handling hazardous gases.

- If your primary focus is equipment uptime and longevity: Implement a strict preventative maintenance schedule focused on door seals, thermocouples, and the gas delivery system.

Ultimately, success with an atmosphere furnace is achieved by treating it not as a simple oven, but as the precision chemical system it is.

Summary Table:

| Operational Consideration | Key Details |

|---|---|

| Atmosphere Composition | Control gas purity and ratios to prevent defects and ensure process success. |

| System Integrity | Maintain seals and monitor pressure to keep atmosphere contained and stable. |

| Dynamic Control | Actively manage temperature and gas flow throughout the process cycle. |

| Material Preparation | Clean parts thoroughly to avoid contamination and ensure consistent results. |

| Safety Protocols | Implement gas monitoring, explosion-proof devices, and emergency procedures for hazardous gases. |

| Operator Skills | Require trained professionals in gas handling, chemical safety, and metallurgical processes. |

| Maintenance | Conduct regular checks on seals, thermocouples, and gas systems for uptime and longevity. |

Struggling with the complexities of atmosphere furnace operations? KINTEK is here to help! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Ensure safety, efficiency, and reliability in your processes—contact us today for expert support and tailored solutions!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing