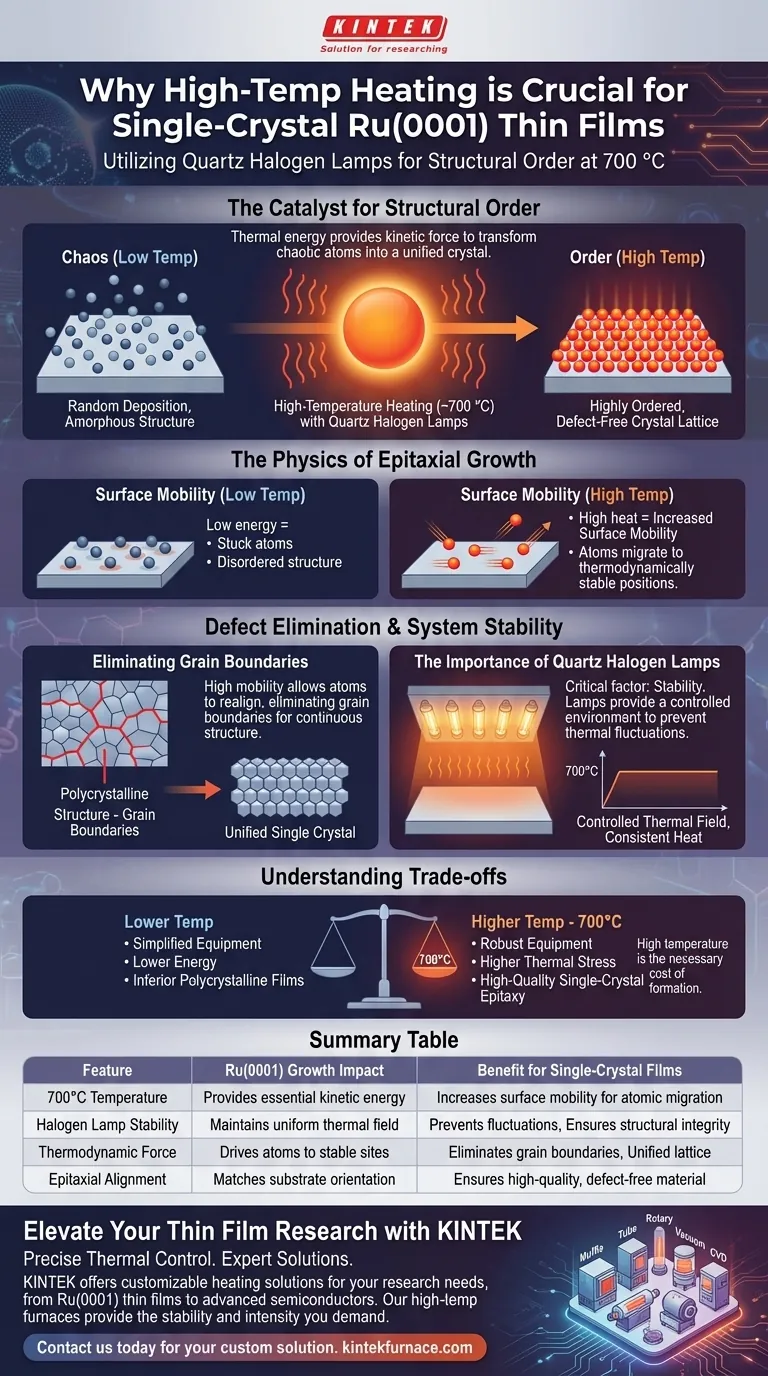

High-temperature heating systems are the catalyst for structural order. In the preparation of single-crystal Ru(0001) thin films, systems utilizing quartz halogen lamps are necessary to maintain a stable thermal environment, typically around 700 °C. This thermal energy provides the kinetic force required to transform a chaotic deposition of atoms into a highly ordered, defect-free crystal lattice.

The application of high heat increases the surface mobility of deposited atoms, allowing them to migrate to thermodynamically stable lattice positions. This migration is essential for eliminating grain boundaries and achieving high-quality epitaxial growth.

The Physics of Epitaxial Growth

The Role of Surface Mobility

When atoms are sputtered onto a substrate, they initially land in random configurations. Without sufficient energy, they remain "stuck" where they land, leading to disordered or amorphous structures.

High-temperature heating injects energy into these deposited atoms. This added energy dramatically increases their surface mobility, granting them the freedom to move across the substrate surface rather than locking instantly into place.

Achieving Thermodynamic Stability

The goal of single-crystal growth is to arrange atoms in their lowest energy state. This state corresponds to the most thermodynamically stable lattice positions.

By maintaining a temperature of approximately 700 °C, you ensure that atoms have enough kinetic energy to "hunt" for these optimal sites. They migrate until they settle into the precise alignment dictated by the underlying sapphire substrate.

Defect Elimination and System Stability

Eliminating Grain Boundaries

One of the primary antagonists in thin film preparation is the formation of grain boundaries—interfaces where crystals of different orientations meet. These defects compromise the integrity of the material.

The high mobility afforded by the heating system allows atoms to realign and merge into a single continuous structure. This process effectively eliminates grain boundary defects, ensuring the film grows as a unified single crystal rather than a patchwork of smaller grains.

The Importance of Quartz Halogen Lamps

The reference specifically highlights the use of quartz halogen lamps to achieve this environment. The critical factor here is not just heat, but stability.

Quartz halogen lamps provide a controlled thermal field. This consistency is vital, as thermal fluctuations during the sputtering process could interrupt the migration of atoms, reintroducing defects or halting epitaxial growth.

Understanding the Trade-offs

Thermal Budget vs. Material Quality

Implementing a high-temperature system introduces complexity to the deposition setup. Achieving 700 °C requires robust equipment capable of handling significant thermal stress.

However, this is the necessary cost of quality. While lower temperatures would simplify the equipment requirements and reduce energy consumption, they would fail to provide the mobility needed for single-crystal formation, resulting in inferior, polycrystalline films.

Making the Right Choice for Your Goal

To ensure successful thin film preparation, align your thermal strategy with your specific structural requirements:

- If your primary focus is achieving single-crystal epitaxy: You must prioritize a heating system capable of maintaining a stable 700 °C to guarantee sufficient atomic mobility.

- If your primary focus is minimizing structural defects: Rely on the high-temperature thermal field to drive atoms into stable lattice positions, thereby eliminating grain boundaries.

Ultimately, the quality of your Ru(0001) thin film is directly proportional to the stability and intensity of the thermal environment provided during deposition.

Summary Table:

| Feature | Ru(0001) Growth Impact | Benefit for Single-Crystal Films |

|---|---|---|

| 700°C Temperature | Provides essential kinetic energy | Increases surface mobility for atomic migration |

| Halogen Lamp Stability | Maintains uniform thermal field | Prevents fluctuations that cause structural defects |

| Thermodynamic Force | Drives atoms to stable sites | Eliminates grain boundaries for a unified lattice |

| Epitaxial Alignment | Matches substrate orientation | Ensures high-quality, defect-free material integrity |

Elevate Your Thin Film Research with KINTEK

Precise thermal control is the difference between a disordered film and a high-quality single crystal. Backed by expert R&D and manufacturing, KINTEK offers a wide range of specialized heating solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet your specific research needs.

Whether you are developing Ru(0001) thin films or advanced semiconductors, our lab high-temp furnaces provide the stability and intensity your process demands. Contact us today to find your custom solution!

Visual Guide

References

- Quintin Cumston, William E. Kaden. Wafer-scale development, characterization, and high temperature stabilization of epitaxial Cr2O3 films grown on Ru(0001). DOI: 10.1063/5.0201818

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why are high-purity graphite electrodes necessary for Joule heating? Ensure Precise Mesoporous Carbon Engineering

- What are the main advantages of graphite heating elements in vacuum ovens? Unlock Extreme Heat & Purity

- Why are Silicon Carbide (SiC) heating elements and recrystallized alumina tubes used in vertical tube furnaces?

- What materials are commonly used in heating elements and why? Discover the Best Choices for Your Thermal Systems

- What are the advantages of using MoSi2 heating elements? Achieve High-Temperature Reliability and Efficiency

- What are the common types of ceramic heating elements? Find the Right Heater for Your Application

- What are the key properties required in materials used for heating elements? Choose the Right Material for Efficient, Durable Heating

- What are the temperature capabilities of silicon carbide heating elements? Achieve High Heat for Industrial Processes