In a vacuum environment, graphite heating elements are chosen for their unmatched high-temperature performance, durability, and chemical purity. Their ability to operate reliably at temperatures far exceeding those of most metallic elements, combined with their inherent stability, makes them the standard for many demanding industrial processes like heat treating, brazing, and sintering.

The decision to use graphite isn't just about reaching high temperatures; it's about achieving process stability and purity in an extreme environment. Its unique combination of thermal, mechanical, and chemical properties makes it a predictable and reliable choice for the most demanding vacuum furnace applications.

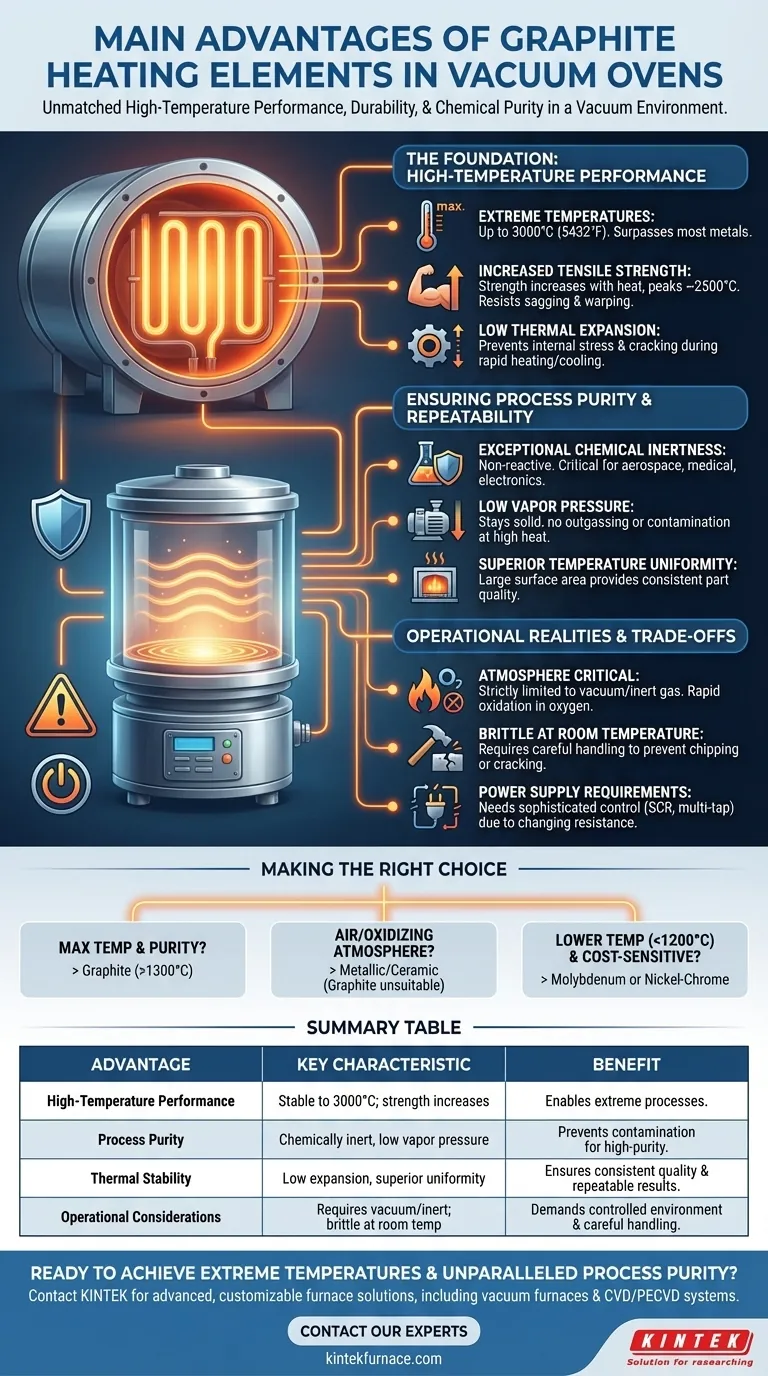

The Foundation: High-Temperature Performance

Graphite's core advantage lies in how its physical properties behave under extreme heat, which is fundamentally different from traditional metals.

Reaching Extreme Temperatures

Graphite elements can operate stably at temperatures up to 3000°C (5432°F) in a vacuum or inert atmosphere. This capability far surpasses the limits of common metallic heating elements.

Mechanical Strength at High Heat

Unlike metals that soften and weaken as they get hotter, graphite's tensile strength actually increases with temperature, peaking around 2500°C. This unique property means graphite elements resist sagging, warping, and mechanical failure under load at extreme temperatures.

Low Thermal Expansion

Graphite has a very low coefficient of thermal expansion. This means it expands and contracts very little during the rapid heating and cooling cycles common in vacuum furnace operations, preventing internal stress that could lead to cracking or failure.

Ensuring Process Purity and Repeatability

In a vacuum, the heating element itself can become a source of contamination. Graphite’s properties are uniquely suited to maintaining a clean processing environment.

Exceptional Chemical Inertness

Graphite is chemically inert and will not react with or contaminate the vast majority of materials being processed. This is critical for high-purity applications in the aerospace, medical, and electronics industries.

Low Vapor Pressure

At high temperatures and in a deep vacuum, materials can begin to "boil" or outgas, contaminating the furnace and the product. Graphite has an extremely low vapor pressure, meaning it remains in a solid state and does not release unwanted vapors, ensuring process purity.

Superior Temperature Uniformity

Graphite elements can be machined into large, robust plates or cylinders. This large surface area allows them to radiate heat very evenly throughout the furnace's hot zone, which is essential for consistent part quality and repeatable results.

Understanding the Trade-offs and Operational Realities

No material is perfect. The decision to use graphite requires understanding its specific operational constraints.

The Critical Role of the Atmosphere

Graphite’s high-temperature strength is strictly limited to vacuum or inert gas environments. In the presence of oxygen at high temperatures, graphite will rapidly oxidize (burn). A leak in the vacuum vessel can lead to the complete destruction of the heating elements.

Brittleness at Room Temperature

While incredibly strong when hot, graphite is a ceramic material and is brittle at room temperature. This requires careful handling during furnace installation, maintenance, and loading to prevent chipping or cracking.

Power Supply Requirements

Graphite's electrical resistance changes as its temperature changes. This necessitates a more sophisticated power control system, typically involving a multi-tap transformer or an SCR (Silicon Controlled Rectifier), to manage the power input accurately throughout a heating cycle.

Making the Right Choice for Your Process

Your specific application dictates whether graphite is the optimal choice over other materials like molybdenum, tungsten, or nickel-chrome alloys.

- If your primary focus is maximum temperature and purity: Graphite is the superior choice for processes above 1300°C, especially where metal contamination is a critical failure point.

- If your primary focus is operating in an air or oxidizing atmosphere: Graphite is unsuitable without complex and expensive protective coatings; you must use metallic or ceramic elements designed for those conditions.

- If your primary focus is cost-sensitivity for lower-temperature vacuum work: For processes consistently below 1200°C, molybdenum or advanced nickel-chrome alloys may offer a more economical solution.

Understanding these core principles allows you to select not just a component, but the right foundation for a reliable and repeatable high-temperature process.

Summary Table:

| Advantage | Key Characteristic | Benefit |

|---|---|---|

| High-Temperature Performance | Stable operation up to 3000°C; tensile strength increases with heat | Enables extreme heat treatment, brazing, and sintering processes |

| Process Purity | Chemically inert with low vapor pressure | Prevents contamination for high-purity applications in aerospace, medical, and electronics |

| Thermal Stability | Low thermal expansion and superior temperature uniformity | Ensures consistent part quality and repeatable results |

| Operational Considerations | Requires vacuum/inert atmosphere; brittle at room temperature | Demands controlled environment and careful handling for optimal performance |

Ready to achieve extreme temperatures and unparalleled process purity in your lab?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line, including specialized Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities.

Whether your application requires the extreme heat and chemical inertness of graphite heating elements or another specialized solution, we can help you build a reliable and repeatable high-temperature process.

Contact our experts today to discuss how we can optimize your vacuum furnace operations!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency