While the initial purchase price is higher, graphite's cost-effectiveness in vacuum furnaces is proven by its significantly lower total cost of ownership. This long-term value is driven by its exceptional durability, superior energy efficiency, and minimal maintenance requirements, which more than compensate for the upfront investment over the component's extended lifespan.

The decision to use graphite is not a simple comparison of initial prices; it is a strategic investment in operational efficiency and long-term reliability. Over the furnace's lifecycle, the cumulative savings from reduced energy consumption, maintenance, and downtime consistently outweigh the higher initial expense.

The Financial Case Beyond the Sticker Price

To understand graphite's value, we must look beyond the initial invoice and analyze its impact on operational expenditures (OpEx) over time. The economic benefits accumulate through superior performance and longevity.

Superior Longevity and Durability

Graphite components are built for the extreme environment of a vacuum furnace. They can stably operate at temperatures up to 3000°C in a vacuum or inert atmosphere.

This inherent resilience means graphite parts last significantly longer than alternatives, leading to fewer replacement cycles, reduced material costs, and less production downtime.

Enhanced Energy Efficiency

Graphite possesses very high thermal conductivity. This allows heating elements to transfer heat to the workload quickly and uniformly.

Faster heat-up times and excellent temperature uniformity shorten cycle durations and reduce the energy consumed per cycle, translating directly into lower electricity bills.

Reduced Maintenance and Labor Costs

The lightweight nature of graphite makes components easier and safer to handle during installation and maintenance, reducing associated labor costs.

Furthermore, its high chemical resistance and structural integrity mean less frequent cleaning and repairs, freeing up maintenance teams and maximizing furnace uptime.

The Technical Advantages Driving Economic Value

The financial benefits of graphite are a direct result of its unique physical and chemical properties. These technical characteristics ensure reliable and high-quality furnace operation.

Unmatched Thermal Performance

Graphite's low electrical resistivity allows it to generate heat efficiently and stably when powered. This is the core principle behind its use as a heating element.

Its ability to maintain mechanical strength at extreme temperatures ensures that components like heating elements and retorts do not warp or fail under thermal stress.

Excellent Process Consistency

The uniform heat distribution provided by graphite is critical for processes like sintering, brazing, and annealing. This consistency ensures repeatable, high-quality results from batch to batch.

By minimizing temperature variations within the hot zone, you reduce the risk of scrapped parts and improve overall product yield—a significant, if indirect, cost saving.

High Chemical Purity

Graphite is a highly stable and non-reactive material. It does not easily contaminate the materials being processed inside the furnace.

This purity is essential for high-value industries like electronics, aerospace, and medical manufacturing, where even trace amounts of contamination can render a product useless.

Understanding the Trade-offs and Modern Solutions

While highly effective, choosing graphite involves acknowledging its specific characteristics and how modern engineering addresses them.

The Upfront Investment

The primary trade-off is the higher initial capital expenditure. This requires a financial justification based on total cost of ownership rather than just the purchase price.

Careful Handling Requirements

Although strong, graphite can be brittle and may chip or break if handled improperly. This necessitates established protocols and careful handling during installation or removal to prevent damage.

Mitigating Wear with Innovations

The performance and lifespan of graphite are continually being improved. Protective coatings, such as those based on silicon carbide (SiC), can be applied to significantly increase resistance to oxidation and mechanical wear.

Additionally, custom-designed graphite parts, tailored to a specific furnace's geometry and process, can further enhance efficiency and durability, maximizing the return on investment.

Making the Right Choice for Your Operation

Evaluating graphite requires aligning its benefits with your primary operational goals.

- If your primary focus is minimizing long-term operational costs: Graphite is the definitive choice due to its energy efficiency and low replacement frequency.

- If your primary focus is process quality and repeatability: Graphite's superior temperature uniformity and chemical purity ensure consistent, high-quality output.

- If your primary focus is maximizing production uptime: The exceptional durability of graphite components means fewer failures and less time spent on maintenance and replacement.

Ultimately, choosing graphite is an investment in the long-term reliability and financial health of your vacuum furnace operations.

Summary Table:

| Benefit | Impact on Cost-Effectiveness |

|---|---|

| Superior Longevity | Fewer replacements, reduced downtime |

| High Thermal Conductivity | Faster heat-up, lower energy consumption |

| Minimal Maintenance | Lower labor costs, increased uptime |

| Process Consistency | Higher product yield, fewer defects |

Ready to optimize your vacuum furnace performance with cost-effective graphite solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our expertise in graphite components—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—ensures durability, energy efficiency, and minimal maintenance for your laboratory.

Contact us today to discuss how our deep customization capabilities can enhance your furnace's longevity and ROI!

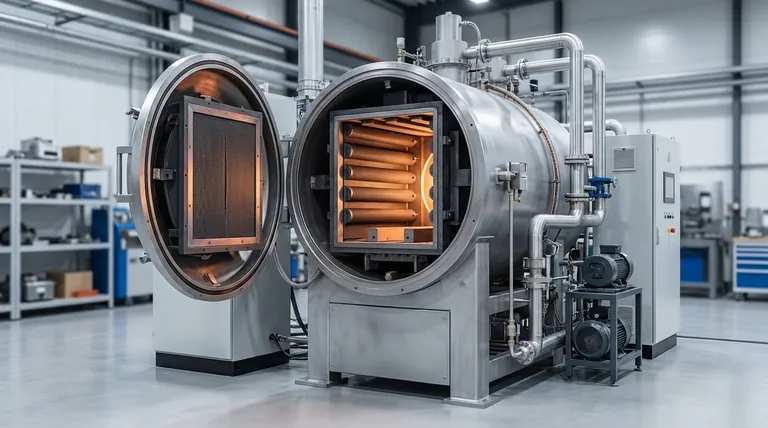

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures