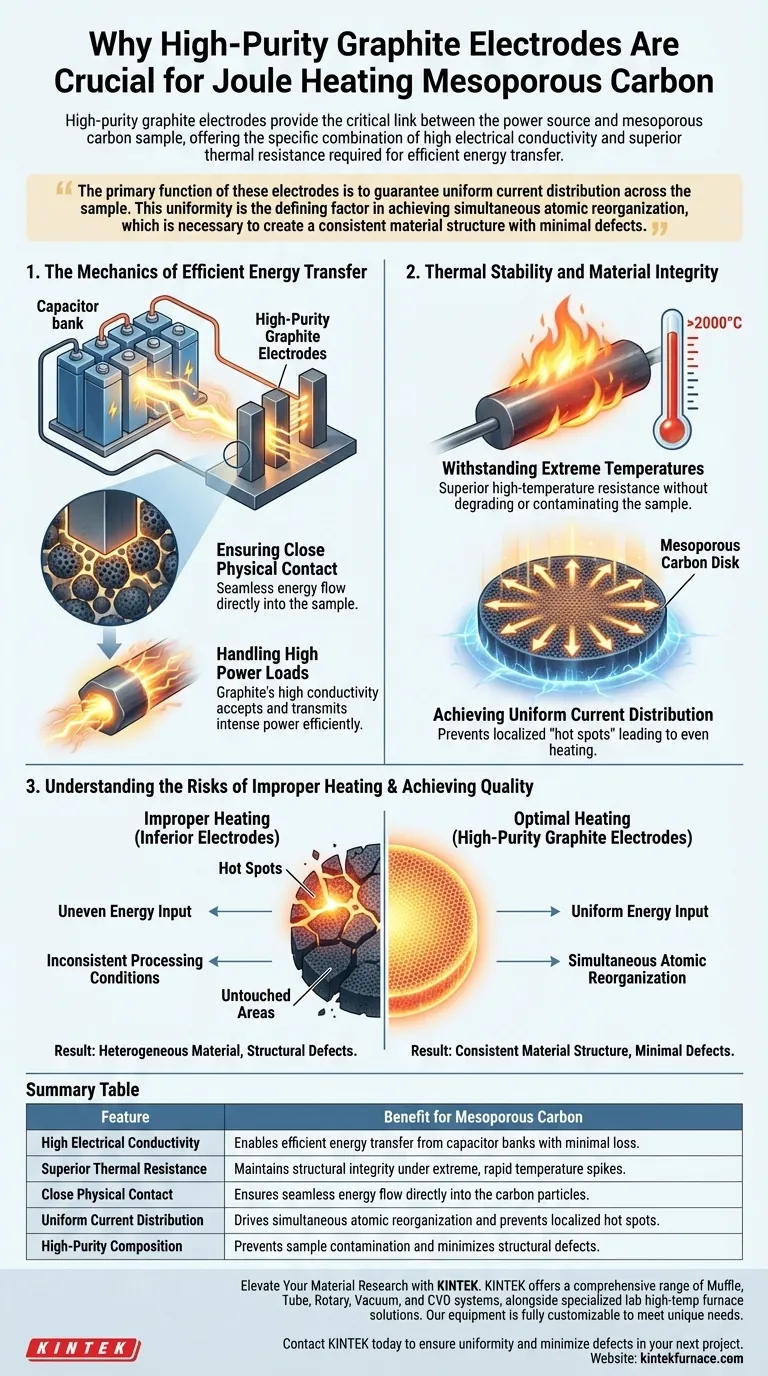

High-purity graphite electrodes are essential for Joule heating because they provide the critical link between the power source and the mesoporous carbon sample. These electrodes offer the specific combination of high electrical conductivity and superior thermal resistance required to transfer powerful energy surges from a capacitor bank efficiently. By maintaining close contact with carbon particles, they prevent energy loss and ensure the process remains stable under extreme conditions.

The primary function of these electrodes is to guarantee uniform current distribution across the sample. This uniformity is the defining factor in achieving simultaneous atomic reorganization, which is necessary to create a consistent material structure with minimal defects.

The Mechanics of Efficient Energy Transfer

Ensuring Close Physical Contact

For Joule heating to be effective, the interface between the energy source and the material must be seamless. High-purity graphite electrodes maintain close contact with the mesoporous carbon particles. This tight interface ensures that the electrical energy flows directly into the sample without significant resistance at the connection points.

Handling High Power Loads

The Joule heating process utilizes a capacitor bank to deliver a rapid, powerful discharge of electrical energy. The electrodes must serve as a robust conduit for this surge. Graphite’s naturally high conductivity allows it to accept and transmit this intense power efficiently, ensuring the energy reaches the sample rather than being dissipated as waste heat in the wiring or connections.

Thermal Stability and Material Integrity

Withstanding Extreme Temperatures

Joule heating is defined by rapid temperature spikes. The electrodes must endure this environment without degrading or contaminating the sample. Graphite offers superior high-temperature resistance, maintaining its structural integrity even during the intense heat generation required to process mesoporous carbon.

Achieving Uniform Current Distribution

The quality of the final product depends entirely on how the electricity travels through the carbon disk. High-purity graphite ensures that the current is distributed uniformly across the entire sample area. This prevents the formation of localized "hot spots" where current might otherwise concentrate, which would lead to uneven heating.

Understanding the Risks of Improper Heating

The Link to Atomic Reorganization

The ultimate goal of this process is to alter the atomic structure of the carbon. Uniform heating drives simultaneous atomic reorganization throughout the sample. If the electrodes fail to distribute current evenly, parts of the sample may reorganize while others remain unchanged, leading to a heterogeneous material.

Minimizing Structural Defects

Defects in mesoporous carbon often stem from inconsistent processing conditions. By ensuring uniform energy input and simultaneous restructuring, high-purity graphite electrodes minimize structural defects. Using inferior electrodes with lower conductivity or poor contact properties would likely result in a flawed final product with compromised mechanical or electrical properties.

Making the Right Choice for Your Goal

Selecting the correct electrode material is not a trivial detail; it is a parameter that dictates the quality of your synthesis.

- If your primary focus is sample homogeneity: Prioritize high-purity graphite to ensure the current is distributed uniformly across the entire mesoporous carbon disk.

- If your primary focus is minimizing defects: Rely on graphite’s high conductivity and thermal resistance to drive simultaneous atomic reorganization, preventing structural inconsistencies.

High-purity electrodes transform a chaotic energy discharge into a precise tool for material engineering.

Summary Table:

| Feature | Benefit for Mesoporous Carbon |

|---|---|

| High Electrical Conductivity | Enables efficient energy transfer from capacitor banks with minimal loss. |

| Superior Thermal Resistance | Maintains structural integrity under extreme, rapid temperature spikes. |

| Close Physical Contact | Ensures seamless energy flow directly into the carbon particles. |

| Uniform Current Distribution | Drives simultaneous atomic reorganization and prevents localized hot spots. |

| High-Purity Composition | Prevents sample contamination and minimizes structural defects. |

Elevate Your Material Research with KINTEK

Precision in Joule heating requires more than just energy; it requires the right environment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnace solutions. Our equipment is fully customizable to meet the unique needs of researchers working with mesoporous carbon and advanced material synthesis.

Don't let equipment limitations compromise your atomic reorganization. Contact KINTEK today to discover how our high-performance thermal solutions can ensure uniformity and minimize defects in your next project.

Visual Guide

References

- Mitesh Ganpat Mapari, Tae Young Kim. Edge‐Free Graphene‐Derived Mesoporous Carbon for High‐Voltage Supercapacitors. DOI: 10.1002/sstr.202500265

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Magnesium Extraction and Purification Condensing Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What makes Iron-Chrome-Aluminium alloys suitable for high-temperature applications? Discover the Power of Self-Healing Alumina Layers

- What are the temperature capabilities of silicon carbide heating elements? Achieve High Heat for Industrial Processes

- What are the common sheath materials for heating elements and their properties? Choose the Best for Your Lab's Needs

- What are the benefits of integrating heating elements and thermocouple systems? Enhance Precision for ECAP Processing

- What is the highest temperature heating element? Tungsten Leads, But Atmosphere is Key

- What is the value of ceramic fiber blankets for cooling slag? Ensuring Precision in Thermal Research

- How do MoSi2 heating elements perform in thermal cycling? Withstand Rapid Temperature Changes

- How does graphite behave under high temperatures compared to other materials? Discover Its Unique Strengths