In short, Molybdenum Disilicide (MoSi₂) heating elements perform exceptionally well under thermal cycling. They are specifically designed to withstand rapid and repeated changes in temperature without significant degradation. This resilience makes them a preferred choice for high-temperature furnaces used in applications like ceramics sintering, materials research, and glass production where fast heating and cooling are required.

The core reason for MoSi₂'s robust thermal cycling performance is its ability to form a protective, self-healing layer of silica glass. While this layer provides outstanding durability during rapid temperature changes, the element's ultimate lifespan is still defined by a slow, inevitable process of oxidation and thinning.

The Science Behind MoSi₂'s Thermal Cycling Resilience

The remarkable performance of MoSi₂ elements during thermal cycling is not an accident; it is a direct result of their fundamental material chemistry when exposed to oxygen at high temperatures.

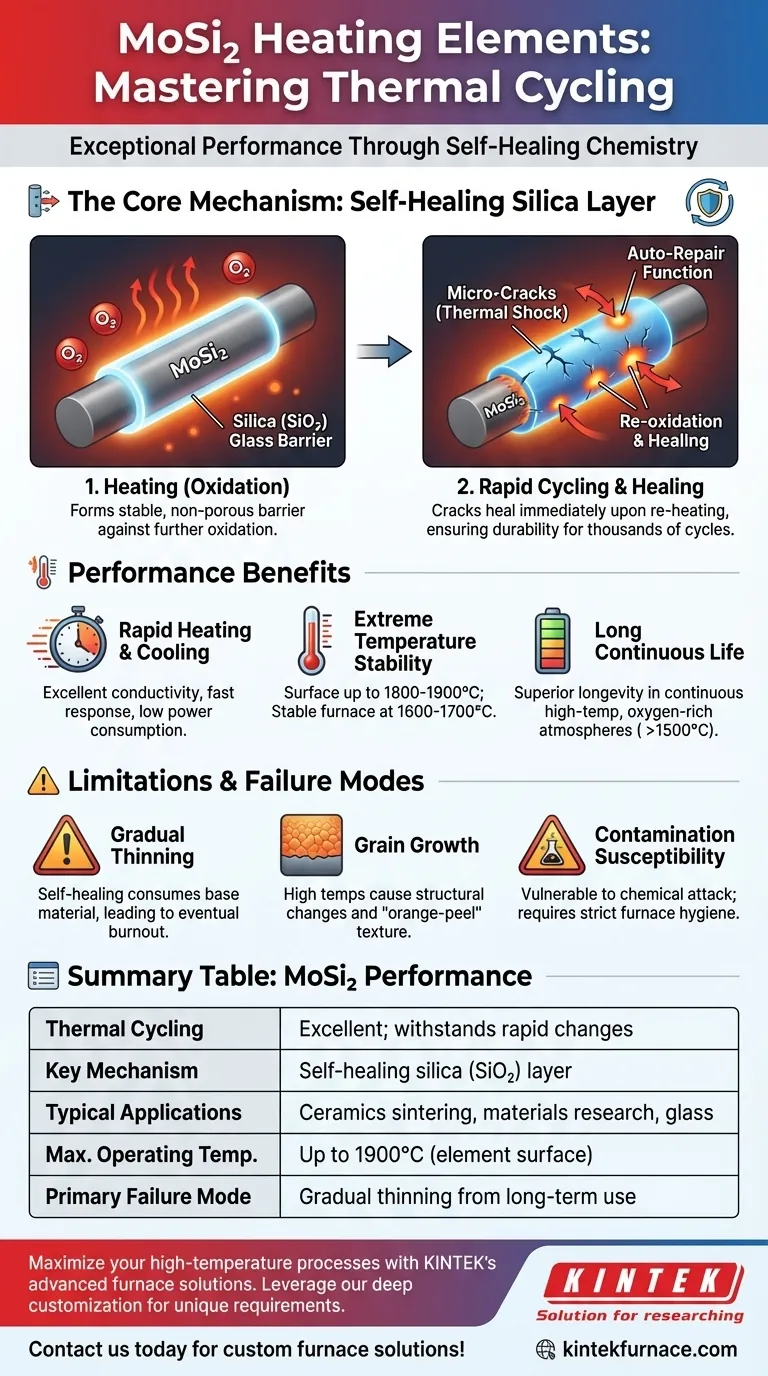

The Self-Healing Silica Layer

When a MoSi₂ element is heated, its surface reacts with oxygen in the atmosphere to form a thin, non-porous, and highly stable layer of silica (SiO₂), which is essentially a type of quartz glass. This layer acts as a protective barrier, preventing further rapid oxidation of the underlying element.

The references describe this as an "antioxidant and auto-repair" function, which is the key to its success.

Rapid Re-formation During Cycling

During a rapid cooling cycle, the protective silica layer may develop microscopic cracks due to thermal shock. However, as soon as the element is heated again, the exposed MoSi₂ material immediately re-oxidizes, effectively "healing" these cracks and restoring the protective barrier. This dynamic process allows the element to endure thousands of cycles.

High Heating Rate and Efficiency

MoSi₂ elements possess excellent electrical conductivity and a high heating rate. This allows them to reach extreme temperatures very quickly with low power consumption, a critical requirement for any application that relies on fast and efficient thermal cycling.

Performance Characteristics at High Temperatures

Beyond thermal cycling, the overall performance profile of MoSi₂ makes it suitable for demanding industrial and laboratory environments.

Exceptional Temperature Stability

These elements are capable of operating at very high temperatures. The surface of the element can reach up to 1800-1900°C, enabling stable furnace chamber temperatures of 1600-1700°C.

Long Service Life in Continuous Operation

When operated continuously in an oxygen-rich atmosphere, particularly above 1500°C, MoSi₂ elements can have a longer service life than common alternatives like Silicon Carbide (SiC). Their stability makes them ideal for sustained high-temperature processes.

Understanding the Trade-offs and Failure Modes

No material is perfect. Acknowledging the limitations and failure mechanisms of MoSi₂ elements is crucial for maximizing their lifespan and ensuring operational safety.

The Inevitable Thinning Process

The "self-healing" process, while effective, is not infinite. Each time the silica layer is formed, a minuscule amount of the base material is consumed. Over a long period of intense use, this leads to a gradual thinning of the element.

Eventually, the element becomes too thin to handle the required power density, leading to localized overheating and burnout.

The Role of Grain Growth

At very high operating temperatures, a phenomenon known as grain growth can occur within the element's structure. This can contribute to the thinning process and sometimes gives the element's surface a characteristic "orange-peel" texture, signaling advanced age.

Susceptibility to Contamination

MoSi₂ elements are highly susceptible to chemical attack from certain contaminants. For example, if painted or colored zirconia is dried improperly in the furnace, the released compounds can aggressively degrade the elements. Poor furnace maintenance is a primary cause of premature failure.

Making the Right Choice for Your Application

Use these points to determine if MoSi₂ is the correct choice for your specific operational goals.

- If your primary focus is rapid heating and cooling cycles: MoSi₂ is an excellent choice due to its self-healing silica layer and fast response time.

- If your primary focus is operating at very high temperatures (above 1500°C): MoSi₂ offers superior longevity and stability in oxygen atmospheres compared to many alternatives.

- If your primary focus is minimizing operational risk: You must enforce strict furnace hygiene and maintenance protocols to prevent contamination, which is a key vulnerability for these elements.

By understanding both its rapid cycling strengths and its gradual failure mechanisms, you can effectively leverage the power of MoSi₂ elements in your high-temperature processes.

Summary Table:

| Aspect | Performance of MoSi₂ Elements |

|---|---|

| Thermal Cycling Resilience | Excellent; withstands rapid, repeated temperature changes. |

| Key Mechanism | Forms a protective, self-healing silica (SiO₂) layer. |

| Typical Applications | Ceramics sintering, materials research, glass production. |

| Maximum Operating Temperature | Up to 1800-1900°C (element surface). |

| Primary Failure Mode | Gradual thinning from oxidation over long-term use. |

Maximize the performance and lifespan of your high-temperature processes with KINTEK's advanced furnace solutions.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether your priority is rapid thermal cycling like that achieved with MoSi₂ elements or stable operation above 1500°C, our expertise ensures you get the right solution for maximum efficiency and durability.

Contact us today to discuss how we can customize a furnace solution for your specific application!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability