In high-temperature industrial and laboratory settings, molybdenum disilicide (MoSi2) heating elements provide a distinct set of advantages centered on their extreme temperature capability, operational longevity, and electrical stability. They can reach operating temperatures far exceeding other metallic elements, offer the longest inherent lifespan in their class, and maintain a consistent resistance that simplifies furnace maintenance and ensures process repeatability.

The core advantage of MoSi2 is not just its ability to get extremely hot, but its unique self-healing protective layer. This mechanism grants it unparalleled stability and durability in oxidizing atmospheres, making it the most reliable and cost-effective choice for demanding, continuous high-temperature processes.

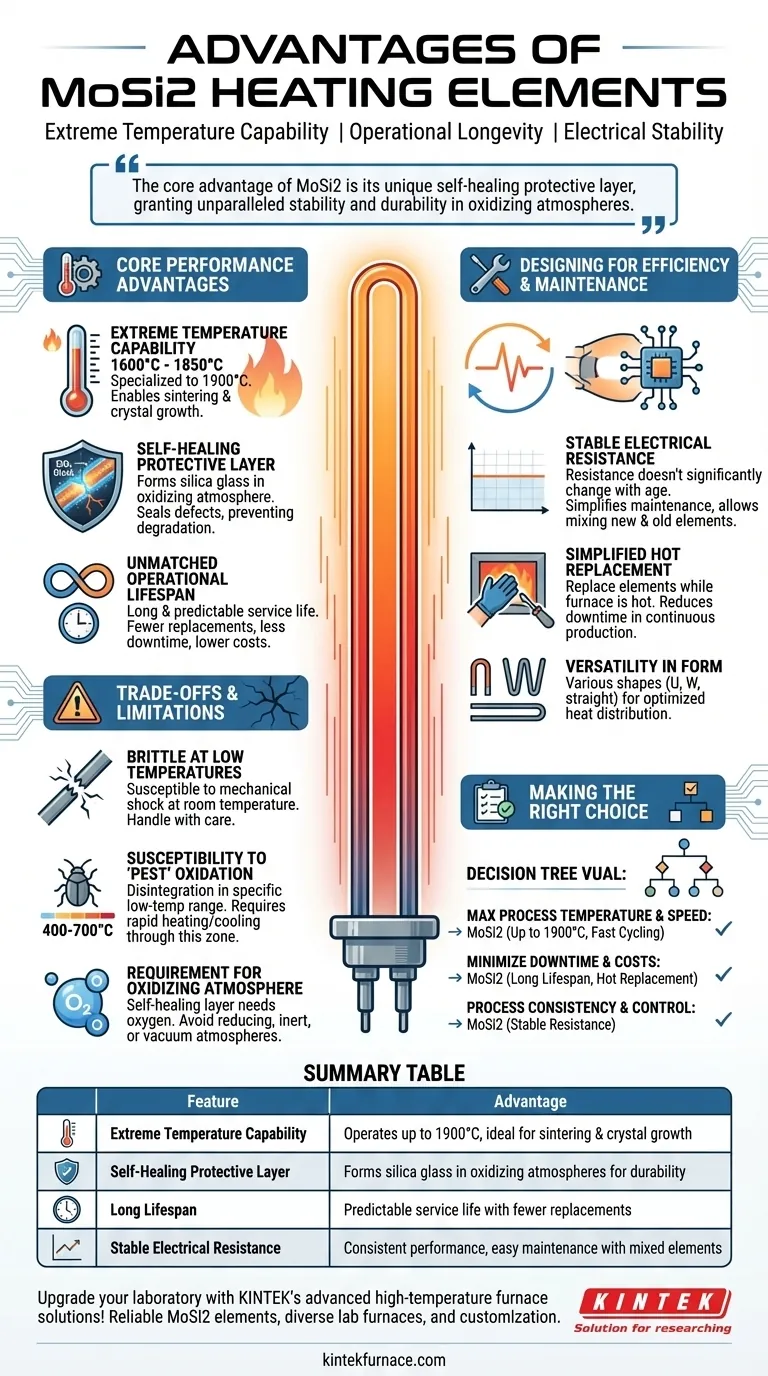

Unpacking the Core Performance Advantages

The properties of MoSi2 elements directly translate into superior furnace performance and reliability, especially when compared to other common heating element materials like silicon carbide (SiC) or metallic alloys.

Extreme Temperature Capability

MoSi2 elements are engineered for the most demanding thermal environments. They can operate continuously at element temperatures between 1600°C and 1850°C (2912°F - 3362°F), with specialized variants reaching up to 1900°C.

This allows for processes that are impossible with other electric elements, such as sintering advanced ceramics, growing crystals, and conducting specific high-temperature metal heat treatments.

The Self-Healing Protective Layer

The defining characteristic of MoSi2 is its "self-healing" nature in an oxidizing atmosphere. As the element heats, it forms a thin, non-conductive protective layer of silica glass (SiO2) on its surface.

If a crack or spall develops on this layer, the underlying MoSi2 material is exposed to oxygen. This exposure instantly forms new silica glass, effectively sealing the defect and preventing the element from degrading.

Unmatched Operational Lifespan

This self-healing mechanism is the primary reason for MoSi2's exceptionally long and predictable service life. Unlike elements that degrade steadily over time, MoSi2 elements maintain their integrity as long as the protective layer can be regenerated.

This results in fewer replacements, less furnace downtime, and lower long-term costs.

Rapid Heating and Thermal Cycling

MoSi2 elements can handle very high watt loadings, enabling fast heating rates. Furthermore, they are not susceptible to damage from rapid thermal cycling, making them ideal for batch processes that require frequent heating and cooling.

Designing for Efficiency and Maintenance

Beyond raw performance, MoSi2 elements possess key features that simplify furnace design, operation, and long-term maintenance.

Stable Electrical Resistance

A crucial operational advantage is that the electrical resistance of MoSi2 does not change significantly with age. This is a stark contrast to materials like silicon carbide, which increase in resistance over their lifespan.

This stability means you can connect new replacement elements in series with older ones without causing power imbalances or needing to replace the entire set, drastically simplifying maintenance.

Simplified Hot Replacement

Due to their robust design and stable properties, MoSi2 elements can often be replaced while the furnace is still hot. This capability is a significant benefit in continuous production environments, as it can reduce furnace downtime from days to mere hours.

Versatility in Form and Application

These elements are manufactured in a wide variety of shapes and sizes, including U-shaped, W-shaped, and straight elements. This design flexibility allows for the optimization of heat distribution within any given furnace chamber.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. To use MoSi2 elements effectively, it is critical to understand their specific operational constraints.

Brittleness at Low Temperatures

Like many ceramic-based materials, MoSi2 is brittle and susceptible to mechanical shock at room temperature. Care must be taken during installation and handling to avoid impact damage. Once at operating temperature, their strength increases significantly.

Susceptibility to "Pest" Oxidation

In a specific low-temperature range of approximately 400-700°C, MoSi2 can experience a catastrophic form of oxidation known as "pesting". This occurs if the element is held in this temperature range for extended periods, causing it to disintegrate. Furnaces must be programmed to heat and cool rapidly through this zone.

Requirement for an Oxidizing Atmosphere

The self-healing silica layer can only form in the presence of oxygen. Using MoSi2 elements in reducing, inert, or vacuum atmospheres without proper protection will prevent the layer from forming or strip it away, leading to rapid element failure.

Making the Right Choice for Your Application

To select the right heating element, align its properties with your primary operational goal.

- If your primary focus is maximum process temperature and speed: The unparalleled temperature ceiling (up to 1900°C) and fast thermal cycling of MoSi2 make it the definitive choice.

- If your primary focus is minimizing downtime and maintenance costs: MoSi2's exceptional lifespan and the ability to mix new and old elements in series significantly reduce long-term operational burdens.

- If your primary focus is process consistency and control: The stable electrical resistance of MoSi2 ensures predictable, repeatable thermal performance over the element's entire life.

Ultimately, choosing MoSi2 is an investment in long-term reliability and performance for the most demanding thermal applications.

Summary Table:

| Advantage | Key Features |

|---|---|

| Extreme Temperature Capability | Operates up to 1900°C, ideal for sintering and crystal growth |

| Self-Healing Protective Layer | Forms silica glass in oxidizing atmospheres for durability |

| Long Lifespan | Predictable service life with fewer replacements |

| Stable Electrical Resistance | Consistent performance, easy maintenance with mixed elements |

| Rapid Heating and Cycling | High watt loadings, handles frequent temperature changes |

| Simplified Hot Replacement | Reduces downtime in continuous processes |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating elements like MoSi2, ensuring extreme temperatures, long lifespan, and stable performance. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet your unique experimental needs. Contact us today to discuss how our solutions can enhance your process efficiency and reduce costs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions