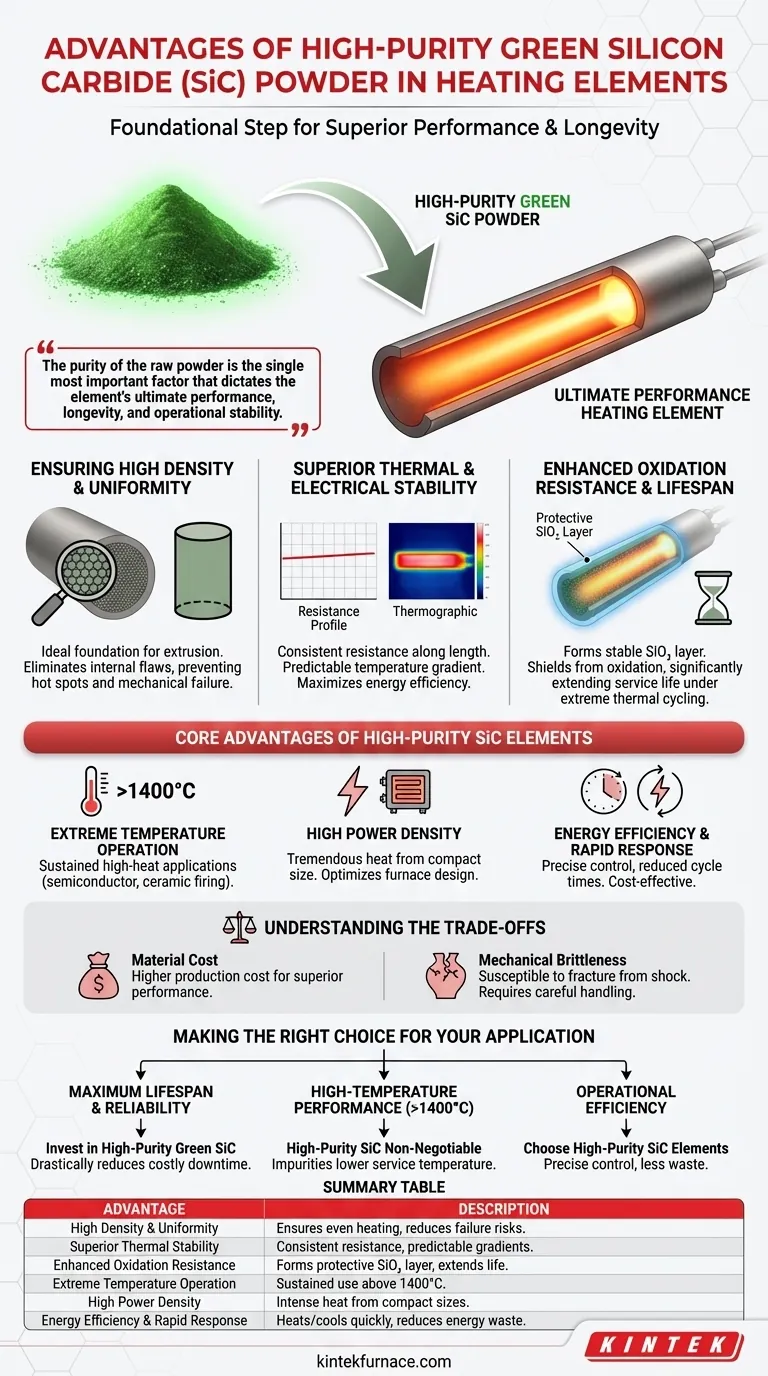

At its core, using high-purity green silicon carbide (SiC) powder is the foundational step for manufacturing superior heating elements. This choice directly translates into a final product with greater density and uniformity, enhanced resistance to oxidation, and a significantly longer and more reliable service life, especially under extreme thermal cycling.

The quality of a silicon carbide heating element is not determined at the final stage of production, but at the very beginning. The purity of the raw powder is the single most important factor that dictates the element's ultimate performance, longevity, and operational stability.

The Direct Link Between Powder Purity and Element Performance

The decision to use high-purity green SiC powder is an investment in reliability. Impurities in lower-grade material act as weak points, leading to premature failure and inconsistent performance.

Ensuring High Density and Uniformity

High-purity powder provides the ideal foundation for the extrusion process. It allows for the creation of a heating element with exceptional density and structural uniformity.

This uniformity is critical because it eliminates internal flaws that can become hot spots or points of mechanical failure over time.

Superior Thermal and Electrical Stability

A uniform element exhibits a consistent electrical resistance profile along its entire length. This ensures even heating and a predictable temperature gradient.

The result is an excellent resistance ratio between the hot zone and the colder terminal ends, maximizing energy efficiency and reducing thermal stress on electrical connections.

Enhanced Oxidation Resistance and Lifespan

In operation, silicon carbide naturally forms a protective surface layer of silicon dioxide (SiO₂), which shields it from oxidation.

High-purity SiC creates a more stable and complete protective film. Impurities can disrupt the formation of this layer, allowing oxygen to penetrate the element and cause gradual degradation, ultimately shortening its service life.

Core Advantages of High-Purity SiC Elements

The superior material foundation provided by high-purity powder unlocks the full potential of silicon carbide as a high-performance heating material.

Extreme Temperature Operation

Silicon carbide heating elements can operate at extremely high temperatures, far exceeding the capabilities of traditional metallic elements like Kanthal or Nichrome.

This makes them essential for applications like semiconductor manufacturing, ceramic firing, and metal heat treatment that require intense, sustained heat.

High Power Density

High power density means the elements can generate a tremendous amount of heat from a compact size.

This is a significant advantage in furnace design, allowing for smaller furnace chambers or higher heat output without increasing the equipment's footprint.

Energy Efficiency and Rapid Response

SiC elements heat and cool quickly, allowing for precise temperature control and reduced cycle times.

Their ability to hold heat efficiently means less energy is wasted during operation, making them a more cost-effective choice for energy-intensive industrial processes.

Understanding the Trade-offs

While high-purity SiC offers superior performance, it's important to understand the associated considerations. No material choice is without its trade-offs.

Material Cost

High-purity green silicon carbide is inherently more expensive to produce than lower-grade or black silicon carbide. This initial material cost is the primary trade-off for its superior performance and longevity.

Mechanical Brittleness

Like most ceramics, silicon carbide is hard but brittle. It has excellent strength under compression but is susceptible to fracture from mechanical shock or impact.

Careful handling during installation and maintenance is essential to avoid damage. The design of the furnace must also account for the element's lack of ductility compared to metal alloys.

Making the Right Choice for Your Application

Selecting the right material grade is a balance between performance requirements and budget. The key is to match the material to the demands of the process.

- If your primary focus is maximum lifespan and reliability: Invest in elements made from high-purity green SiC powder, as their resistance to oxidation and thermal cycling drastically reduces costly downtime.

- If your primary focus is high-temperature performance (>1400°C): High-purity SiC is non-negotiable, as impurities in lower-grade materials can lower the maximum service temperature and lead to rapid failure.

- If your primary focus is operational efficiency: The uniform heating and rapid thermal response of high-purity SiC elements provide precise control, reducing energy waste and improving product quality.

Ultimately, choosing a heating element built on a foundation of high-purity powder is a strategic decision to ensure operational excellence.

Summary Table:

| Advantage | Description |

|---|---|

| High Density & Uniformity | Ensures even heating and reduces failure risks from internal flaws. |

| Superior Thermal Stability | Provides consistent electrical resistance for predictable temperature gradients. |

| Enhanced Oxidation Resistance | Forms a protective SiO₂ layer, extending service life under harsh conditions. |

| Extreme Temperature Operation | Capable of sustained use above 1400°C, ideal for high-heat applications. |

| High Power Density | Delivers intense heat from compact sizes, optimizing furnace design. |

| Energy Efficiency & Rapid Response | Heats and cools quickly, reducing cycle times and energy waste. |

Ready to elevate your lab's performance with reliable high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering enhanced efficiency, longevity, and cost savings. Contact us today to discuss how our high-purity SiC heating elements can transform your processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance