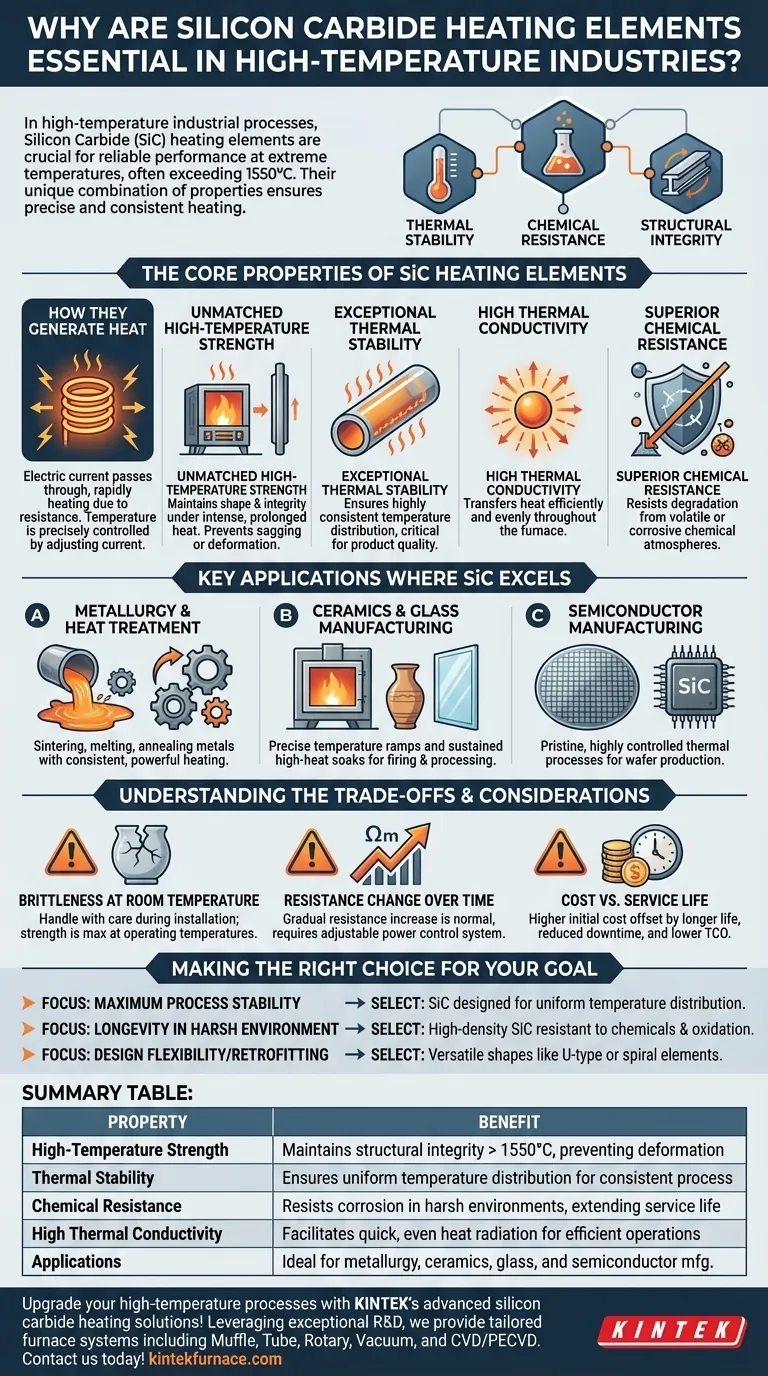

In high-temperature industrial processes, silicon carbide (SiC) heating elements are essential because of their unique ability to perform reliably at extreme temperatures, often exceeding 1550°C. Unlike many other materials, they combine high-temperature strength, chemical inertness, and excellent thermal stability, making them indispensable for applications in metallurgy, ceramics, and semiconductor manufacturing where precise and consistent heating is critical for product quality.

The true value of silicon carbide is not merely its tolerance for heat, but its combination of thermal stability, chemical resistance, and structural integrity. This trifecta enables precise, repeatable process control in demanding environments where other heating elements would degrade or fail.

The Core Properties of SiC Heating Elements

Silicon carbide's effectiveness stems from a specific set of material characteristics that make it uniquely suited for high-heat applications.

How They Generate Heat

The principle is straightforward: an electric current is passed through the SiC element. Due to its electrical resistance, the element rapidly heats up and radiates thermal energy into the furnace or chamber. The temperature is precisely managed by adjusting the electrical current supplied to the element.

Unmatched High-Temperature Strength

SiC elements maintain their structural integrity and shape even when subjected to intense, prolonged heat. This physical robustness prevents sagging or deformation, ensuring a long and predictable service life within a furnace.

Exceptional Thermal Stability

Certain designs, like hollow tubular elements, are optimized for highly consistent temperature distribution. This stability is critical in processes where even minor temperature variations across a product can lead to defects, compromising quality and yield.

High Thermal Conductivity

SiC transfers heat very efficiently. This property ensures that the energy generated is radiated quickly and evenly throughout the furnace, contributing to uniform process conditions.

Superior Chemical Resistance

Many industrial processes, from metal treatment to incineration, involve volatile or corrosive chemical atmospheres. Silicon carbide is highly resistant to chemical attack, preventing degradation and ensuring the element's longevity in these harsh environments.

Key Applications Where SiC Excels

The properties of SiC make it the default choice for a range of critical industrial processes that require reliable, high-temperature heating.

Metallurgy and Heat Treatment

Processes like sintering, melting, and annealing metals demand consistent and powerful heating. SiC elements provide the high temperatures and stability needed to achieve specific metallurgical properties.

Ceramics and Glass Manufacturing

Firing kilns for ceramics or processing glass requires precise temperature ramps and sustained high-heat soaks. SiC elements deliver the control necessary to execute these complex thermal profiles without failure.

Semiconductor Manufacturing

The production of semiconductors relies on pristine, highly controlled thermal processes. The stability and clean operation of SiC heaters are vital for creating the perfect conditions needed for wafer processing.

Understanding the Trade-offs and Considerations

While SiC offers significant advantages, it's important to understand the operational considerations to ensure successful implementation.

Brittleness at Room Temperature

Like many ceramics, silicon carbide can be brittle and must be handled with care during installation and maintenance, especially when at room temperature. Its strength is most prominent at operating temperatures.

Resistance Change Over Time

Over their operational lifespan, SiC elements experience a gradual increase in electrical resistance. This aging process is normal and predictable. However, it requires a power control system (like an SCR or a multi-tap transformer) that can adjust the output voltage to compensate for this change and maintain consistent power delivery.

Cost vs. Service Life

The initial procurement cost of SiC elements can be higher than that of standard metallic heating elements. This initial investment is typically offset by their significantly longer service life, reduced furnace downtime, and lower replacement frequency, resulting in a lower total cost of ownership over time.

Making the Right Choice for Your Goal

When selecting a heating solution, your primary objective should guide your decision.

- If your primary focus is maximum process stability and product quality: Prioritize SiC elements specifically designed for uniform temperature distribution, as their consistency directly impacts yield.

- If your primary focus is longevity in a harsh chemical environment: Select a high-density SiC element known for its superior resistance to chemical attack and oxidation.

- If your primary focus is design flexibility or retrofitting an existing furnace: Consider versatile shapes like U-type or spiral elements that can be mounted vertically or horizontally to simplify installation.

Ultimately, choosing silicon carbide is an investment in process reliability and control, ensuring repeatable, high-quality results where extreme heat is non-negotiable.

Summary Table:

| Property | Benefit |

|---|---|

| High-Temperature Strength | Maintains structural integrity above 1550°C, preventing deformation |

| Thermal Stability | Ensures uniform temperature distribution for consistent process control |

| Chemical Resistance | Resists corrosion in harsh environments, extending service life |

| High Thermal Conductivity | Facilitates quick, even heat radiation for efficient operations |

| Applications | Ideal for metallurgy, ceramics, glass, and semiconductor manufacturing |

Upgrade your high-temperature processes with KINTEK's advanced silicon carbide heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing reliability, efficiency, and product quality. Contact us today to discuss how we can optimize your operations and deliver long-term value!

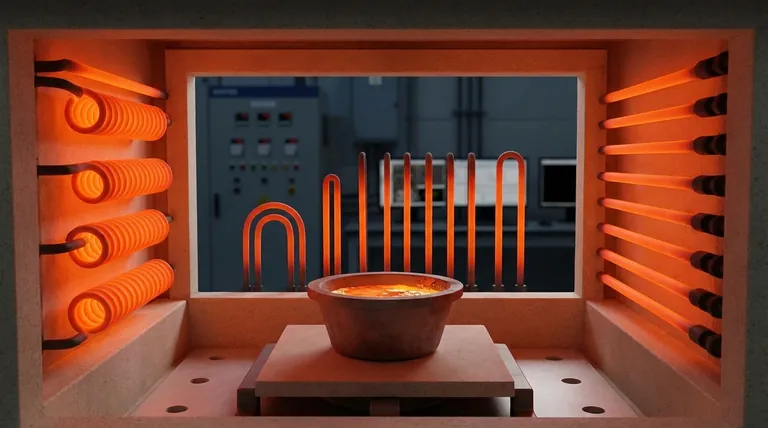

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights