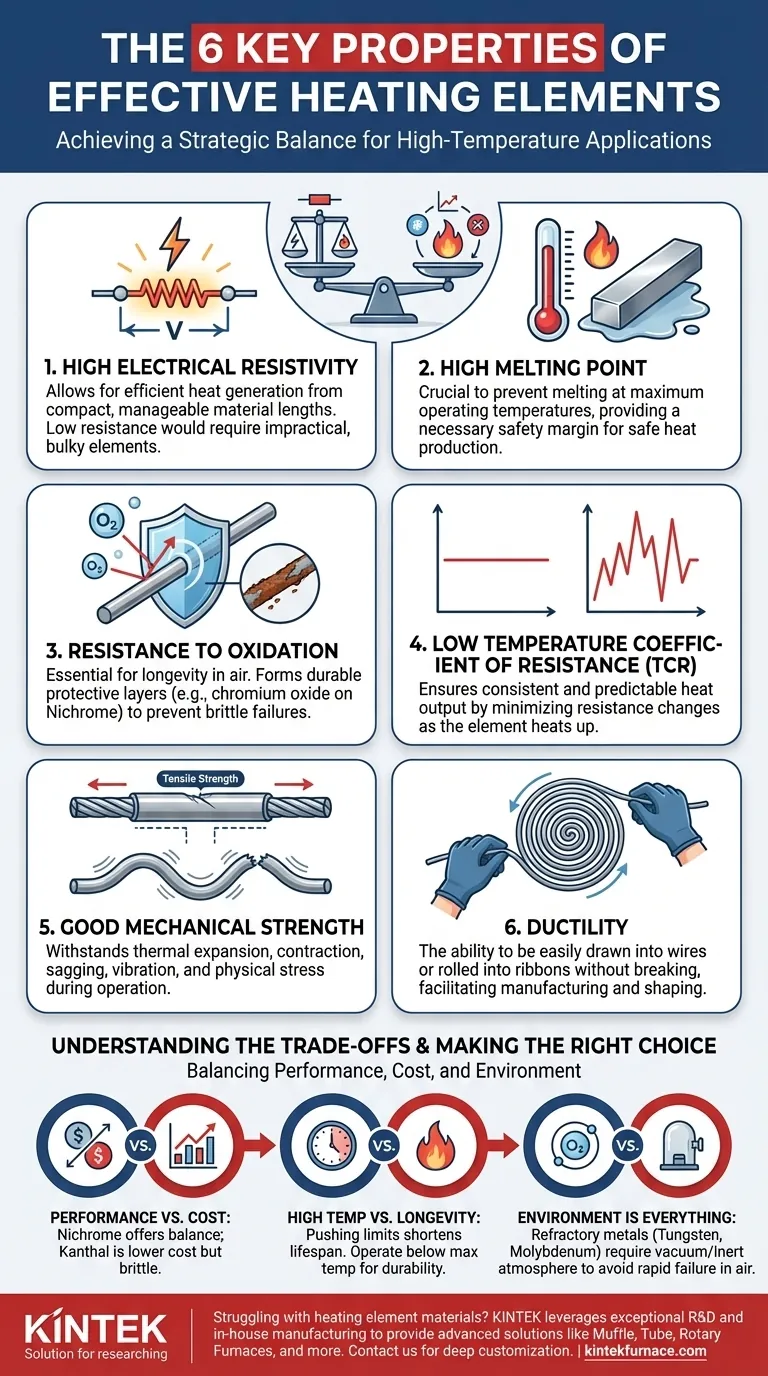

At its core, an effective heating element material must possess six key properties. These include a high melting point, high electrical resistivity, strong resistance to oxidation at high temperatures, a low temperature coefficient of resistance, good mechanical strength, and enough ductility to be formed into wires or other shapes.

The central challenge in selecting a heating element material is not finding a single perfect property, but achieving a strategic balance. The goal is to find a material that can efficiently convert electricity into heat while simultaneously surviving the extreme thermal and chemical stresses of its own operation.

The Physics of Effective Heating

To understand the material requirements, we must first look at the principle of resistive heating, governed by Joule's first law. This law states that the power (heat) generated is proportional to the material's resistance and the square of the current passing through it.

High Electrical Resistivity

High resistivity is the most fundamental requirement. It allows a significant amount of heat to be generated from a physically short and manageable length of material.

If a material had low resistance, you would need a very long wire to generate the same amount of heat, making the final appliance impractical and bulky.

High Melting Point

The purpose of a heating element is to get very hot. The material's melting point must be substantially higher than its maximum operating temperature to provide a safe margin and prevent it from melting.

This property dictates the upper limit of how much heat an element can safely produce.

The Battle for Longevity and Stability

Generating heat is only half the battle. A good heating element must also be durable and perform predictably over thousands of hours of use. This is where thermal and chemical stability become critical.

Resistance to Oxidation

Most heating elements operate in open air. At high temperatures, oxygen aggressively reacts with metals, forming brittle oxides that can cause the element to thin, increase in resistance, and eventually fail.

Materials like Nichrome (nickel-chromium) are prized because they form a thin, durable, and adherent outer layer of chromium oxide. This layer acts as a protective barrier, preventing further oxidation of the metal underneath and dramatically extending the element's life.

Stable Temperature Coefficient of Resistance (TCR)

A material's resistance changes with temperature. A low, or stable, TCR means that the resistance does not fluctuate wildly as the element heats up from room temperature to its operating point.

This stability is crucial for performance. It ensures that the heat output remains consistent and predictable, which is essential for applications like ovens and industrial furnaces that require precise temperature control.

Mechanical Durability (Ductility & Strength)

A heating element material must be manufactured, shaped, and installed. Ductility is the ability to be drawn into a wire or rolled into a ribbon without breaking.

Once installed, the element must also have sufficient tensile strength to withstand sagging, vibration, and the stresses of repeated thermal expansion and contraction without failing.

Understanding the Trade-offs

No single material is perfect for every application. The choice always involves balancing performance, cost, and the operating environment.

Performance vs. Cost

Nichrome (Ni-Cr) alloys are the workhorse for general-purpose heating. They offer an excellent balance of ductility, long life due to oxidation resistance, and a stable TCR.

Kanthal (Fe-Cr-Al) alloys are often used as a lower-cost alternative. They can achieve higher operating temperatures than Nichrome but are more brittle, making them harder to work with.

High Temperature vs. Longevity

Pushing any material closer to its maximum temperature limit drastically shortens its lifespan. The rate of oxidation increases exponentially with temperature, leading to faster degradation and failure.

Designing for longevity often means selecting a material and operating it well below its absolute maximum temperature rating.

Environment is Everything

The presence of oxygen is the defining factor. Materials like Tungsten and Molybdenum have exceptionally high melting points but oxidize and fail almost instantly in open air at high temperatures.

However, in a vacuum or an inert gas atmosphere where there is no oxygen, these refractory metals become the ideal choice for the most extreme high-temperature applications.

Making the Right Choice for Your Goal

Selecting a material is an engineering decision based on the primary objective of the heating application.

- If your primary focus is reliability and long life in general-purpose applications (up to ~1150°C): Nichrome alloys are the industry standard due to their excellent oxidation resistance and good mechanical properties.

- If your primary focus is reaching the highest possible temperatures in air (up to ~1400°C): Fe-Cr-Al (Kanthal) alloys are the superior choice, provided you can accommodate their more brittle nature.

- If your primary focus is extreme temperatures in a vacuum or inert atmosphere: Refractory metals like Molybdenum and Tungsten are the only viable options.

- If your primary focus is precise, stable heat output: Prioritize a material with the lowest possible Temperature Coefficient of Resistance (TCR) within your required temperature range.

Ultimately, choosing the right material ensures the heating element is not just a component, but a reliable and efficient core of your design.

Summary Table:

| Property | Importance | Common Materials |

|---|---|---|

| High Melting Point | Prevents melting at high temperatures | Tungsten, Molybdenum |

| High Electrical Resistivity | Efficient heat generation in compact forms | Nichrome, Kanthal |

| Resistance to Oxidation | Extends lifespan in air environments | Nichrome, Fe-Cr-Al alloys |

| Low Temperature Coefficient of Resistance | Ensures stable heat output | Nichrome, specialized alloys |

| Good Mechanical Strength | Withstands thermal and physical stresses | Various alloys |

| Ductility | Allows shaping into wires or ribbons | Nichrome, some Fe-Cr-Al alloys |

Struggling to select the right heating element material for your lab's high-temperature needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental requirements are met precisely. Contact us today to enhance your lab's efficiency and reliability with tailored heating solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment