High-purity quartz acts as the definitive barrier between the harsh synthesis environment and the integrity of the crystal growth process. In the Chemical Vapor Deposition (CVD) of Molybdenum Phosphide (MoP), this material is selected because it combines exceptional thermal stability with chemical inertness. This ensures the reaction chamber withstands the high temperatures required for synthesis without reacting with precursors like red phosphorus or molybdenum, thereby preventing contamination.

The selection of high-purity quartz is a strategic necessity to create a contaminant-free environment, ensuring that the resulting Molybdenum Phosphide crystals exhibit their true intrinsic electrocatalytic properties rather than artifacts from impurities.

The Role of Chemical Inertness

Preventing Wall Reactions

The primary risk in high-temperature crystal growth is the potential for the reaction vessel to become a reactant itself.

High-purity quartz is chemically inert to the aggressive precursors used in this process, specifically red phosphorus vapor and molybdenum foil. By refusing to react with these materials, the quartz tube ensures that the chemical potential is directed entirely toward the formation of the crystal, rather than the corrosion of the chamber walls.

Ensuring Intrinsic Purity

For researchers studying the electrocatalytic properties of MoP, purity is paramount.

Even trace amounts of contamination from a reaction chamber can alter the electronic structure of a single crystal. By using high-purity quartz, you eliminate external variables, guaranteeing that the performance data collected accurately reflects the intrinsic nature of the Molybdenum Phosphide.

Thermal Stability and Process Control

Withstanding Synthesis Temperatures

The CVD process for MoP requires a rigorous thermal environment to drive the reaction.

Liquid-metal-assisted CVD typically operates within a furnace temperature range of 700°C to 900°C. High-purity quartz maintains its structural integrity and mechanical strength within this window, preventing deformation that could compromise the vacuum seal or the physical shape of the growing crystal.

Facilitating Precision Growth

The stability of the quartz tube allows for precise regulation of the internal environment.

Because the tube does not degrade at these temperatures, it enables the furnace to effectively manage the diffusion kinetics of molybdenum atoms. This stability is critical for controlling specific growth facets, such as the (0001) or (1010) planes, allowing for tailored crystal structures.

Understanding the Trade-offs

The Requirement for "High Purity"

It is critical to distinguish between standard quartz and high-purity quartz.

Using lower-grade quartz or glass substitutes can introduce trace mineral impurities that diffuse into the reaction zone at 900°C. If the quartz is not of sufficient purity, it may devitrify (crystallize) or release contaminants, negating the benefits of the CVD process and ruining the sample.

Mechanical Vulnerability

While thermally robust, quartz remains a brittle ceramic material.

It requires careful handling during loading and unloading, particularly when establishing the vacuum environment (often around 4×10^-6 Torr). Any micro-fractures introduced during handling can propagate under thermal stress, leading to catastrophic failure of the sealed environment.

Making the Right Choice for Your Goal

When designing a CVD experiment for metal phosphides, the reaction vessel determines the reliability of your data.

- If your primary focus is Electrocatalytic Analysis: Prioritize chemical inertness; use certified high-purity quartz to ensure that any catalytic activity observed is inherent to the MoP crystal and not a result of doping from the tube walls.

- If your primary focus is Crystal Morphology Control: Prioritize thermal stability; ensure the tube is rated for continuous operation at 900°C to allow for the precise temperature regulation required to grow specific crystal facets.

By isolating the reaction in high-purity quartz, you convert a volatile chemical process into a controlled environment for precision materials science.

Summary Table:

| Property | Benefit for MoP Synthesis | Impact on Crystal Quality |

|---|---|---|

| Chemical Inertness | Resists red phosphorus & Mo vapor | Prevents contamination and doping artifacts |

| Thermal Stability | Maintains integrity at 700°C - 900°C | Ensures vacuum seal & precise diffusion kinetics |

| High Purity Grade | Zero trace mineral diffusion | Guarantees intrinsic electrocatalytic properties |

| Structural Strength | Supports high-vacuum environments | Stable growth of specific facets like (0001) |

Elevate Your Research with KINTEK’s Precision Engineering

Don't let impurities compromise your crystal growth. KINTEK provides high-performance, high-purity quartz components and advanced thermal solutions designed for the most demanding CVD processes.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet your unique synthesis needs, ensuring your MoP single crystals achieve their true intrinsic potential.

Ready to optimize your lab's performance?

Contact our specialists today to find your custom solution!

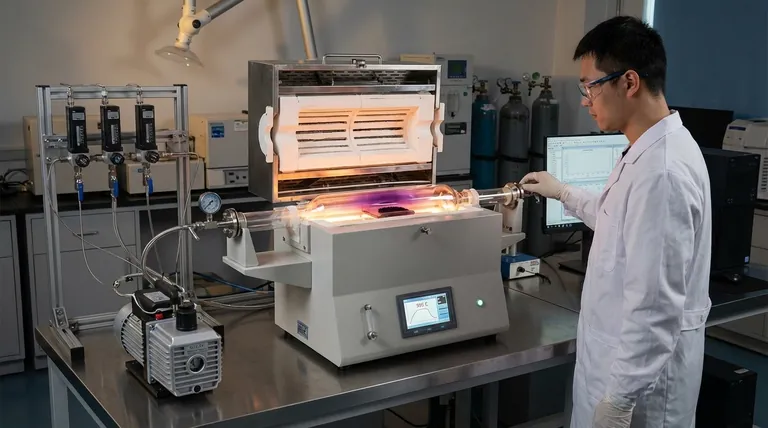

Visual Guide

References

- Seo Hyun Kim, Hyeuk Jin Han. Facet‐Controlled Growth of Molybdenum Phosphide Single Crystals for Efficient Hydrogen Peroxide Synthesis. DOI: 10.1002/adma.202500250

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- How does a dual-temperature zone furnace facilitate the synthesis of beta-Cu2-xSe? Master AP-CVD Thermal Control

- How does CVD enhance cutting tools and industrial machinery? Boost Durability and Productivity

- What are the primary application areas of CVD technology? Unlock Advanced Thin-Film Solutions for Your Industry

- What are the advantages of using in-situ CVD for Ag-ZIF-8/Ni foam? Enhance Structural Stability & Uniformity

- What are the main benefits of Chemical Vapor Deposition? Achieve Superior Film Quality and Versatility

- How does Thermal Chemical Vapor Deposition work? Unlock High-Purity Thin Film Deposition

- What is the significance of nitrogen flow in BN@C pyrolysis? Ensuring Material Purity & Reaction Stability

- In which industry is CVD frequently used, and for what specific application? Discover Its Role in Semiconductors and Beyond