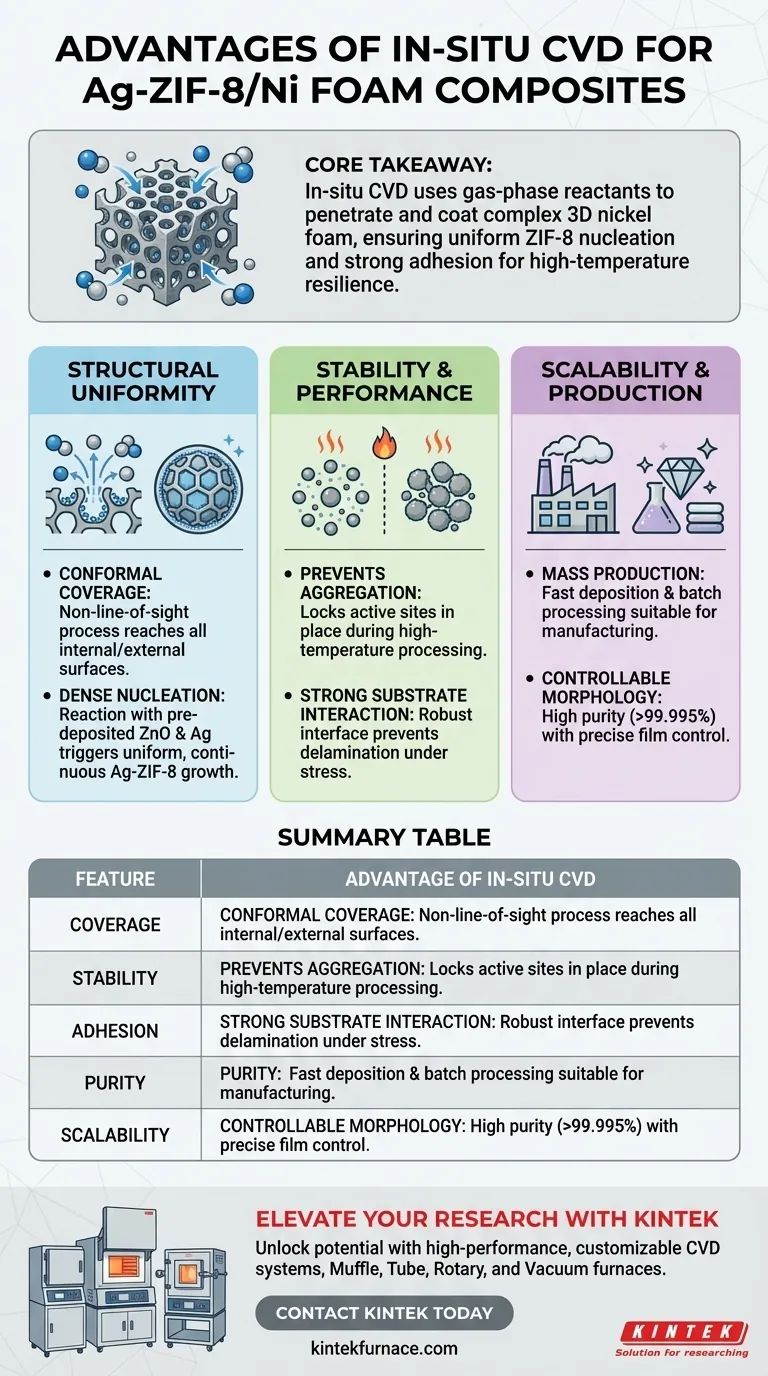

The primary advantage of the in-situ Chemical Vapor Deposition (CVD) method for preparing Ag-ZIF-8/Ni foam composites is the creation of a uniform, strongly adhered coating that resists degradation. By reacting 2-methylimidazole vapor directly with a silver-doped Zinc Oxide (ZnO) layer on the foam, this technique ensures dense ZIF-8 nucleation while preventing the aggregation of active sites during high-temperature operations.

Core Takeaway Coating complex 3D structures like nickel foam is challenging due to the difficulty of reaching internal surfaces and ensuring adhesion. In-situ CVD solves this by using gas-phase reactants to penetrate the foam's intricate geometry, locking active components in place to maintain performance under thermal stress.

Achieving Structural Uniformity on Complex Substrates

The physical architecture of nickel foam is irregular and porous, making it difficult to coat using traditional line-of-sight methods. CVD addresses this geometric challenge through its unique growth mechanism.

Conformal Coverage of Internal Surfaces

Because CVD utilizes gaseous reactants, it is a non-line-of-sight process. The vapor can penetrate deep into the complex, porous structure of the nickel foam. This ensures that the ZIF-8 framework grows uniformly on all internal and external surfaces, rather than just the outer edges.

Dense Nucleation via In-Situ Reaction

The method does not simply deposit a layer on top of the substrate; it grows the layer from the substrate. By reacting 2-methylimidazole vapor with the pre-deposited ZnO and silver, the process triggers uniform nucleation. This results in a dense, continuous coverage of Ag-ZIF-8 across the entire foam surface.

Enhancing Material Stability and Performance

Beyond physical coverage, the chemical interactions induced by this method significantly improve the longevity and resilience of the composite material.

Prevention of Active Site Aggregation

A critical failure point in many composite catalysts is the clumping (aggregation) of active particles when exposed to heat. The in-situ CVD approach locks the silver and ZIF-8 components firmly in place. This effectively prevents the migration and aggregation of active sites during subsequent high-temperature processing, preserving the material's catalytic efficiency.

Stronger Substrate Interaction

The direct reaction between the vapor and the pre-deposited layer creates a robust interface between the active components and the nickel foam base. This strong adhesion reduces the likelihood of the coating delaminating or flaking off during operation, a common issue with films produced via less integrated deposition methods.

Scalability and Production Efficiency

While the chemical benefits are paramount, the CVD process also offers distinct advantages regarding manufacturing and scalability.

Suitability for Mass Production

CVD is characterized by fast deposition speeds and the ability to batch process materials. The stability and repeatability of the process make it highly suitable for mass production, allowing for the creation of high-purity coatings without significant variation between batches.

Controllable Surface Morphology

The gas-phase nature of the process allows for precise control over the film's growth. This results in films that are not only pure (often exceeding 99.995% purity) but also possess a controllable morphology, which is essential for tailoring the material's specific optical, thermal, or electrical properties.

Understanding the Trade-offs

While in-situ CVD offers superior coating quality, it is essential to recognize the inherent requirements of the process to ensure it fits your specific constraints.

Chemical Management

The process relies on chemical reactions that can generate byproducts. While modern equipment is often self-cleaning, you must have protocols in place for handling chemical byproducts and ensuring the safety of the specific precursors used (such as 2-methylimidazole vapor).

Substrate Compatibility

Success relies heavily on the initial preparation of the substrate. The nickel foam must be pre-deposited with silver and Zinc Oxide (ZnO) correctly for the in-situ reaction to occur. Inaccuracies in this pre-deposition phase will directly impact the quality of the final ZIF-8 growth.

Making the Right Choice for Your Goal

The decision to use in-situ CVD should be driven by the specific performance requirements of your final composite structure.

- If your primary focus is thermal stability: This method is ideal because it prevents the aggregation of active sites during high-temperature applications.

- If your primary focus is complex geometry: Use this approach to ensure uniform, conformal coating on the internal surfaces of the porous nickel foam.

- If your primary focus is coating adhesion: This technique is superior for creating a strong chemical bond between the active ZIF-8 layer and the metal substrate.

By leveraging the gas-phase penetration of CVD, you transform a fragile foam into a robust, high-performance composite capable of withstanding rigorous operational environments.

Summary Table:

| Feature | Advantage of In-Situ CVD |

|---|---|

| Coverage | Conformal, non-line-of-sight coating of complex 3D porous structures |

| Stability | Prevents aggregation of active sites during high-temperature operations |

| Adhesion | Strong chemical bonding between ZIF-8 and substrate reduces delamination |

| Purity | Produces high-purity (up to 99.995%) coatings with controllable morphology |

| Scalability | High deposition speeds suitable for batch processing and mass production |

Elevate Your Composite Material Research with KINTEK

Unlock the full potential of your material science projects with precision-engineered systems. Backed by expert R&D and manufacturing, KINTEK offers high-performance CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces—all fully customizable to meet your unique research and production needs.

Whether you are coating complex 3D substrates or requiring extreme thermal stability, our lab solutions provide the control and purity you need to succeed.

Ready to optimize your deposition process? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- M. Nur Hossain, Gianluigi A. Botton. Efficient Electrochemical CO<sub>2</sub> Reduction Using AgN<sub>3</sub> Single‐Atom Sites Embedded in Free‐Standing Electrodes for Flow Cell Applications. DOI: 10.1002/smsc.202400643

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What limitations does CVD have in coating large surfaces? Overcome Scale Challenges with Custom Solutions

- What are the characteristics of the coating film produced by CVD? Achieve Superior Thin Films for Your Applications

- Why must a CVD system use high-precision MFCs? Achieve Atomic Perfection in Your Material Synthesis

- What environmental conditions does a quartz tube reactor provide for CNT growth? Optimize Your CVD Process Today

- How does a CVD system facilitate RuTe2 nanoparticle formation? Precision Control for Advanced Synthesis

- Why is CVD considered a scalable process? Unlock High-Volume, Uniform Coatings for Your Industry

- How does Thermal Chemical Vapor Deposition work? Unlock High-Purity Thin Film Deposition

- What non-metal elements are commonly deposited using CVD? Discover Silicon and Carbon Applications