The fundamental limitation of Chemical Vapor Deposition (CVD) for large surfaces is the physical size of the vacuum chamber. While the process excels at creating highly uniform and adherent coatings, scaling the required high-temperature vacuum environment to accommodate very large or bulky components presents significant engineering and economic challenges. These challenges extend beyond mere physical dimensions into the core difficulty of maintaining precise process control over a vast area.

While CVD provides superior coating adhesion and coverage, its use on large surfaces is fundamentally constrained by the practical and economic limits of building and operating massive, high-temperature vacuum systems while ensuring uniform process conditions.

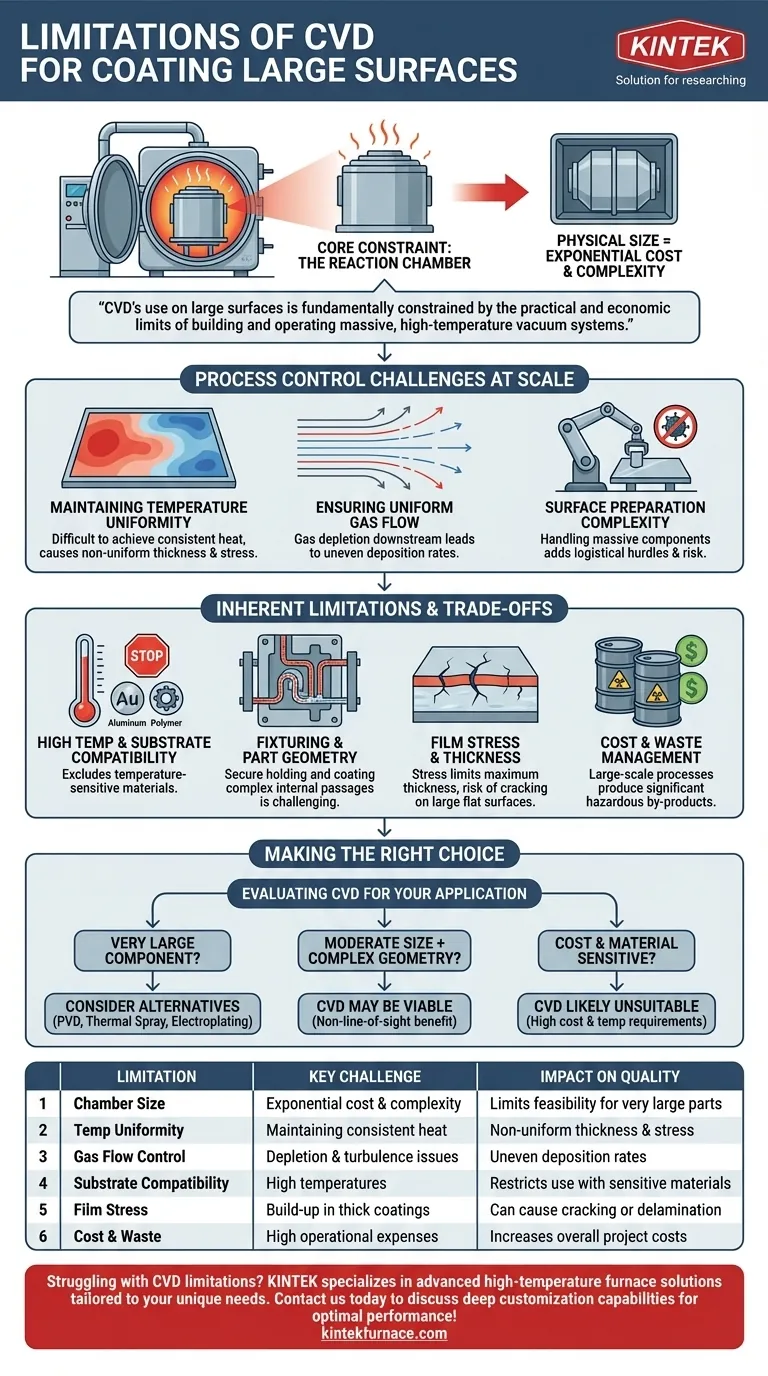

The Core Constraint: The Reaction Chamber

The heart of the CVD process is the vacuum chamber, and its size is the first and most significant barrier to coating large components.

Physical Size and Cost

CVD chambers are complex, high-pressure vessels that must withstand extreme temperatures and vacuum conditions. Increasing the size is not a linear cost increase; it is an exponential jump in engineering complexity, material cost, and manufacturing difficulty.

Vacuum and Temperature Demands

A larger chamber volume requires more powerful and expensive pumping systems to achieve the necessary vacuum. More importantly, it requires an immense amount of energy to heat uniformly to the high temperatures (often >800°C) needed to drive the chemical reaction, making the process itself significantly more costly for large parts.

Process Control Challenges at Scale

Even if a sufficiently large chamber is built, maintaining the precise conditions required for a high-quality coating across a large surface introduces another layer of complexity.

Maintaining Temperature Uniformity

Achieving a consistent temperature across a massive component inside a chamber is exceptionally difficult. Any hot or cold spots on the surface will cause variations in the coating's reaction rate, leading to non-uniform thickness, stress, and performance.

Ensuring Uniform Gas Flow

The precursor gases must flow evenly over the entire surface to ensure a consistent deposition rate. On large parts, gas can become depleted as it reacts, meaning areas "downstream" of the gas inlet may receive less precursor, resulting in a thinner coating. Preventing turbulence and ensuring uniform boundary layers is a major fluid dynamics challenge.

Surface Preparation Complexity

CVD requires an atomically clean surface for optimal adhesion. Manually or automatically cleaning, handling, and loading a massive component without introducing contaminants is a significant logistical hurdle that adds to the overall process complexity and risk.

Understanding the Trade-offs and Inherent Limitations

Beyond the primary challenges of scale, other inherent properties of the CVD process become more pronounced with larger components.

High Temperatures and Substrate Compatibility

The high-temperature requirement of most CVD processes immediately rules out coating large components made from temperature-sensitive materials like aluminum alloys, polymers, or certain heat-treated steels that would be weakened by the process.

Fixturing and Part Geometry

Designing fixtures to hold a massive, heavy part securely inside the reactor without masking surfaces or disrupting gas flow is a non-trivial engineering task. While CVD is not a line-of-sight process, complex internal passages on a very large part can still be difficult to coat evenly.

Film Stress and Thickness

Internal stress builds up in CVD coatings as they grow, which limits the maximum achievable thickness before the film cracks or delaminates. This effect can be more problematic on large, flat surfaces that may be more susceptible to bowing or warping under coating-induced stress.

Cost and Waste Management

A large-scale CVD process produces a proportionally large volume of hazardous and toxic by-products. The cost and complexity of safely handling and disposing of this waste are significant operational factors that scale directly with the size of the components being coated.

Making the Right Choice for Your Application

Evaluating whether CVD is appropriate requires balancing its advantages against its scaling challenges.

- If your primary focus is coating a very large component: Critically evaluate if CVD's benefits justify the high cost and engineering hurdles; alternative technologies like Physical Vapor Deposition (PVD), thermal spray, or electroplating are often more practical.

- If your component is moderately large but has complex internal geometries: CVD's non-line-of-sight capability might make it the only viable option, justifying the higher cost compared to line-of-sight processes.

- If cost and material compatibility are your main drivers: The high operational costs and temperature requirements of large-scale CVD will likely make it an unsuitable choice for your project.

Understanding these scaling limitations is the first step in selecting a coating strategy that is not only technically feasible but also economically viable for your project.

Summary Table:

| Limitation | Key Challenge | Impact on Coating Quality |

|---|---|---|

| Chamber Size | Exponential cost and complexity increase | Limits feasibility for very large parts |

| Temperature Uniformity | Difficulty in maintaining consistent heat | Causes non-uniform thickness and stress |

| Gas Flow Control | Depletion and turbulence issues | Leads to uneven deposition rates |

| Substrate Compatibility | High temperatures exclude sensitive materials | Restricts use with alloys, polymers, etc. |

| Film Stress | Build-up in thick coatings | Can cause cracking or delamination |

| Cost and Waste | High operational expenses and hazardous by-products | Increases overall project costs |

Struggling with CVD limitations for large surfaces? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems with strong deep customization capabilities. Whether you're dealing with complex geometries or require precise process control, our expertise ensures optimal performance and cost-efficiency. Contact us today to discuss how we can enhance your coating processes and overcome scale challenges!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis