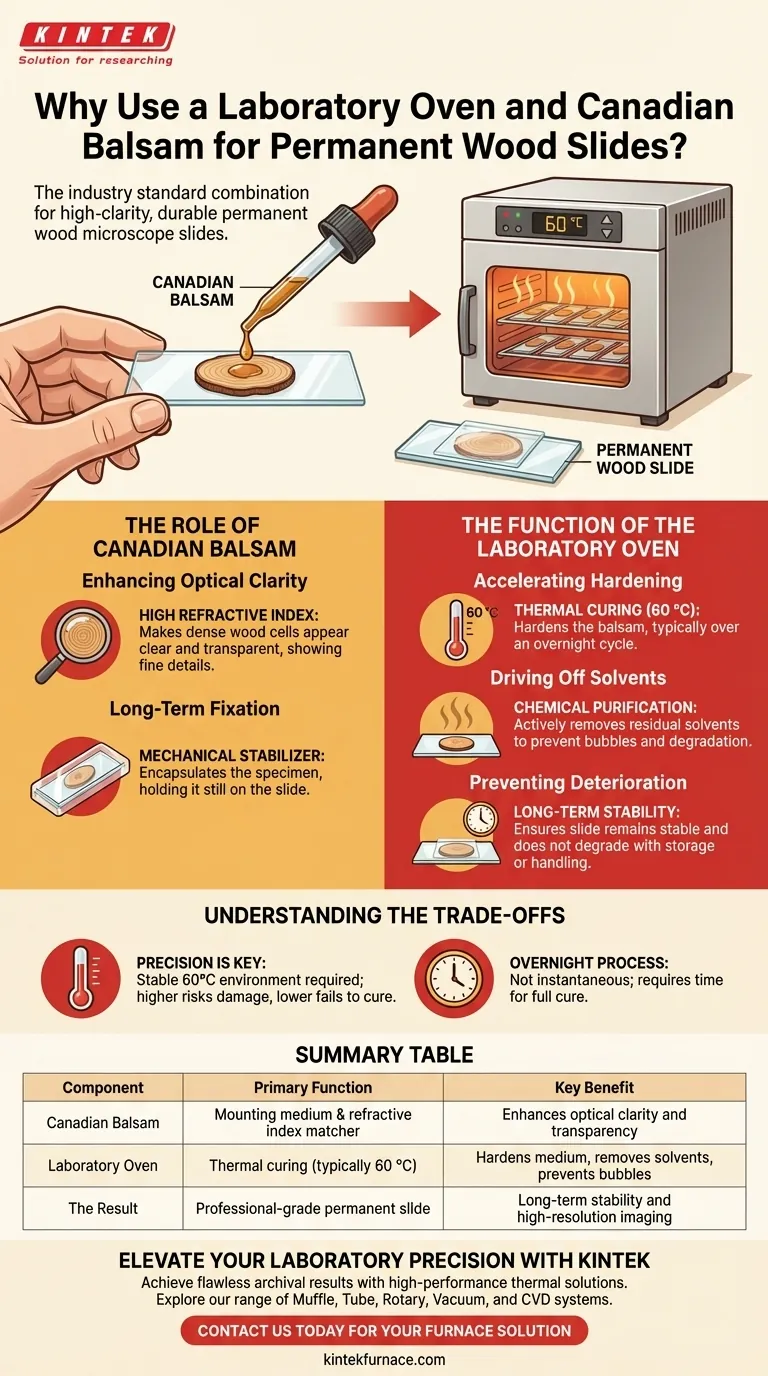

The combination of Canadian Balsam and a laboratory oven is the industry standard for creating professional-grade, permanent wood microscope slides. Canadian Balsam serves as a high-clarity mounting medium to enhance visibility, while the laboratory oven provides the thermal energy required to cure the slide effectively and ensure it lasts for years without deterioration.

Canadian Balsam provides the high refractive index necessary to visualize dense wood cell structures, while the laboratory oven serves as the catalyst for permanence by driving off solvents and hardening the medium.

The Role of Canadian Balsam

Enhancing Optical Clarity

Wood is a naturally dense material that can be difficult to view under a microscope. Canadian Balsam is selected because of its high refractive index.

Creating Transparency

When applied, the balsam interacts with the wood tissue to make cell structures appear clearer and more transparent. This optical property is essential for distinguishing fine details within the wood grain.

Long-Term Fixation

Beyond optics, the balsam acts as a mechanical stabilizer. It encapsulates the wood specimen, holding it perfectly still on the glass slide.

The Function of the Laboratory Oven

Accelerating the Hardening Process

In its raw state, Canadian Balsam remains viscous for a long time. The laboratory oven is used to heat the slides at 60 °C, typically overnight.

Driving Off Residual Solvents

The heating process is not just about drying; it is about chemical purification. The sustained heat actively removes residual solvents trapped within the medium.

Preventing Deterioration

By removing solvents and hardening the balsam quickly, the oven prevents the formation of bubbles. This ensures the slide remains stable and does not degrade during long-term storage or repeated handling.

Understanding the Trade-offs

Temperature Precision

You cannot simply use any heat source. The process requires a stable 60 °C environment; higher temperatures could damage the wood specimen or discolor the balsam, while lower temperatures will fail to cure the medium.

Processing Time

Even with an oven, this is not an instantaneous process. It requires an overnight cycle to ensure the center of the slide is fully cured, meaning workflow planning is essential.

Making the Right Choice for Your Goal

To ensure your wood slides are both viewable and durable, consider the following principles:

- If your primary focus is image quality: Rely on Canadian Balsam for its refractive properties to make the cellular structure of the wood visible and distinct.

- If your primary focus is archival preservation: Do not skip the oven curing step, as removing solvents is the only way to prevent bubbling and deterioration over time.

By combining the optical chemistry of the balsam with the controlled physics of the oven, you create a specimen that is both clear to view and built to last.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Canadian Balsam | Mounting medium & refractive index matcher | Enhances optical clarity and transparency of wood cells |

| Laboratory Oven | Thermal curing (typically 60 °C) | Hardens medium, removes solvents, and prevents bubbles |

| The Result | Professional-grade permanent slide | Long-term stability and high-resolution imaging for years |

Elevate Your Laboratory Precision with KINTEK

Achieve flawless archival results in your material analysis with high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces. Whether you are preparing delicate biological slides or conducting advanced industrial heat treatments, our systems are fully customizable to meet your unique research needs.

Ready to optimize your lab's efficiency? Contact us today to find the perfect furnace solution for your application!

Visual Guide

References

- Issah Chakurah, Enoch Gbapenuo Tampori. The Effect of Thermal Modification on Anatomical Properties of Daniellia oliveri (Rolfe) Hutch and Dalziel from Ghana. DOI: 10.5552/drvind.2025.0218

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of using oriented single-crystal seeds for ZnGeP2? Achieve Precision in Optical Crystal Growth

- Why is a constant-temperature blast drying oven necessary for processing biomass precursors? Ensure Structural Integrity

- How does the carbon reductant ratio influence the selective reduction of ferronickel? Mastering Alloy Purity

- What are the drawbacks of large industrial ovens? Avoid Costly Inefficiencies and Boost Productivity

- Why pre-treat nanopowders in an industrial oven? Optimize Epoxy Nanocomposite Strength and Consistency

- What are the technical advantages of using an industrial-grade microwave-assisted hydrothermal synthesis system? Master CeO2 Morphology

- Why is precise nitrogen flow critical for AlN nanofibers? Mastering High-Performance Nitridation Results

- What role does a PID controller play in the calcination process of eggshells? Precision Control for Pure Calcium Oxide