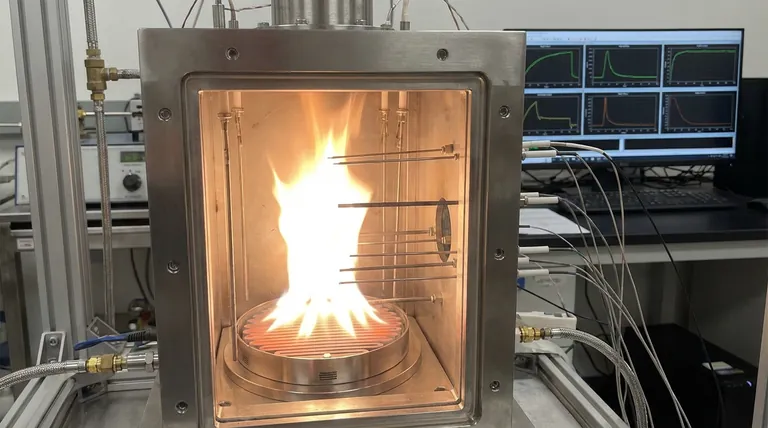

Precise spatial arrangement acts as a filter for thermal complexity. In magnesium combustion experiments, this arrangement is necessary to construct a rigorous heat balance model, allowing researchers to separate the heat generated by chemical reactions from the heat supplied by the ignition source or lost to the environment. Without these specific locations, it is impossible to distinguish between the various mechanisms driving temperature changes.

Core Takeaway

Strategic thermocouple placement transforms aggregate temperature data into a spatially resolved energy map. This differentiation is critical for isolating specific thermal events—such as phase changes and ignition heating—from the actual heat released during combustion.

Constructing the Heat Balance Model

To understand magnesium combustion, you must measure more than just "how hot it gets." You must measure where the energy is flowing. The spatial arrangement of probes creates the framework for a complete energy budget.

Capturing Maximum Intensity

Probes placed near the ignition resistance wire serve a distinct function.

They record the maximum gas-phase temperatures at the heart of the reaction.

This data point establishes the upper limit of thermal intensity within the combustion zone.

Quantifying Environmental Loss

Simultaneously, probes must be positioned near the chamber walls.

These sensors are strictly responsible for evaluating heat loss and dissipation.

By measuring the temperature at the boundaries, researchers can calculate exactly how much energy is escaping to the surrounding environment.

Decoupling Complex Thermal Phenomena

Magnesium combustion is a multi-stage process. A precise sensor array allows you to mathematically disentangle simultaneous physical events.

Distinguishing Heat Sources

A major challenge is separating external energy inputs from internal reaction energy.

Proper spacing allows you to distinguish ignition heating (the energy you put in) from combustion heat release (the energy the magnesium puts out).

This ensures that the efficiency of the fuel is calculated accurately, without interference from the ignition source.

Identifying Energy Sinks

Temperature fluctuations are not always caused by heat generation; sometimes they signal energy consumption.

Spatial precision helps identify phase change energy consumption.

This reveals the specific moments when the magnesium absorbs heat to melt or vaporize, rather than releasing it.

Common Pitfalls in Measurement Strategy

While spatial arrangement provides clarity, it introduces complexity that must be managed. Understanding the limitations of your setup is just as important as the placement itself.

The Risk of Data Homogenization

If probes are placed too close together, their data streams will overlap.

This results in an inability to distinguish between local heat dissipation and active combustion.

You lose the ability to model the heat balance, reverting to a simple, uninformative average temperature.

Misinterpreting Boundary Conditions

Ignoring the chamber walls leads to significant errors in energy calculation.

If you fail to measure the wall temperature specifically, heat loss may be mistaken for a drop in combustion efficiency.

This leads to a fundamental misunderstanding of the material's actual performance.

Making the Right Choice for Your Goal

When designing your experiment, align your thermocouple placement with the specific data you need to extract from the heat balance model.

- If your primary focus is Reaction Intensity: Prioritize placement near the ignition wire to capture the peak gas-phase temperature and combustion heat release.

- If your primary focus is Thermal Efficiency: Ensure robust instrumentation near the chamber walls to strictly quantify heat dissipation and loss to the environment.

- If your primary focus is Material Behavior: Position probes to capture the subtle temperature plateaus that indicate phase change energy consumption.

By treating your thermocouple arrangement as a strategic architecture rather than a random distribution, you turn simple temperature readings into a comprehensive diagnostic of combustion physics.

Summary Table:

| Probe Location | Primary Function | Data Captured |

|---|---|---|

| Near Ignition Wire | Maximum Intensity Measurement | Peak gas-phase temperatures & combustion heat release |

| Near Chamber Walls | Environmental Loss Assessment | Heat dissipation rates & boundary energy escape |

| Specific Material Zones | Phase Change Monitoring | Energy sinks, melting, and vaporization plateaus |

| Strategic Spacing | Data Differentiation | Separation of external heating from chemical reaction heat |

Elevate Your Combustion Research with KINTEK Precision

Precise data starts with a high-performance thermal environment. Backed by expert R&D and manufacturing, KINTEK offers high-temperature Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to accommodate your specific thermocouple arrays and experimental configurations.

Whether you are mapping heat balance models or studying phase changes, our lab furnaces provide the stability and control your magnesium combustion research demands. Our experts are ready to help you design a system tailored to your unique needs.

Contact KINTEK Today to Optimize Your Thermal Setup

Visual Guide

References

- Ioan Barabulica, Ioan Mămăligă. Experimental Study on the Reaction of Magnesium in Carbon Dioxide and Nitrogen Atmosphere. DOI: 10.3390/chemengineering8020041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What properties make graphite heating elements easy to machine? Design Freedom for High-Temp Performance

- Are MoSi2 heating elements environmentally friendly? Discover Their Zero-Emission Benefits

- What types of silicon carbide heating elements are available? Choose the Right Shape for Your High-Temp Needs

- Are molybdenum disilicide heating elements customizable? Tailor High-Temp Solutions for Your Furnace

- What are the requirements for good heating element materials? Optimize Your Heating Solutions with Expert Insights

- What are graphite furnace elements? The Key to Extreme Heat in Industrial Processes

- What is the maximum operating temperature of MoSi2 heating elements? Unlock High-Temp Performance & Longevity

- How do high-precision thermocouples and closed-loop control systems influence nickel silicide film uniformity?