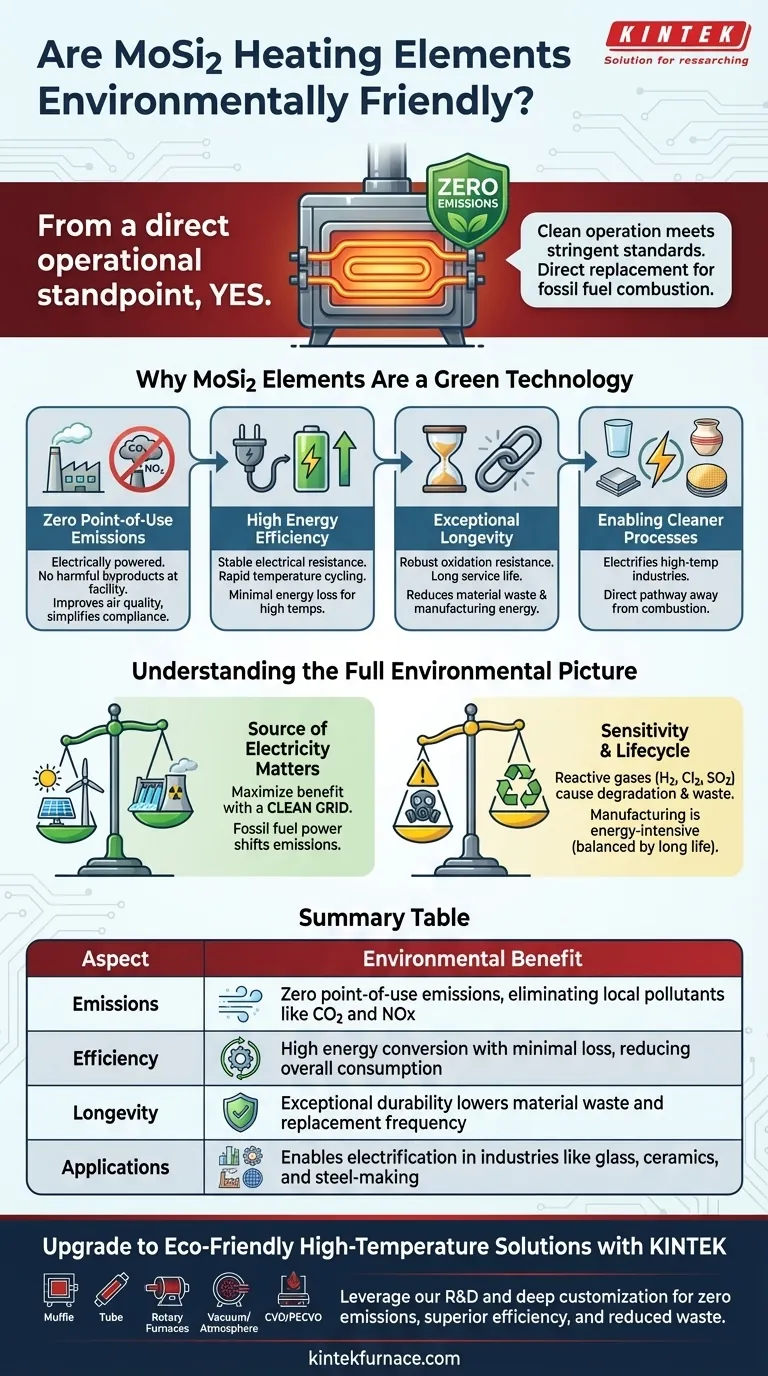

From a direct operational standpoint, yes. Molybdenum disilicide (MoSi2) heating elements are considered environmentally friendly because they produce zero emissions at the point of use. This clean operation allows them to meet stringent environmental protection standards, making them a direct and effective replacement for processes that rely on the combustion of fossil fuels.

The environmental benefit of MoSi2 elements extends beyond just zero emissions. Their true value lies in their high efficiency and exceptional longevity, which reduce overall energy consumption and material waste over the furnace's entire lifecycle.

Why MoSi2 Elements Are a Green Technology

To understand their environmental credentials, we need to look at how they perform in a real-world industrial or laboratory setting. Their benefits are rooted in their material properties.

Zero Point-of-Use Emissions

Unlike gas-fired furnaces that release CO2, NOx, and other pollutants, MoSi2 elements are electrically powered. They generate heat through resistance, producing no harmful byproducts in your facility.

This completely eliminates local emissions, improving air quality and simplifying environmental compliance.

High Energy Efficiency

These elements feature stable electrical resistance and the ability to cycle through temperatures quickly.

This stability means energy is converted to heat with minimal loss, making them a highly efficient choice for reaching and maintaining the extreme temperatures required in modern manufacturing and research.

Exceptional Longevity and Durability

MoSi2 elements are known for their robust resistance to oxidation at high temperatures, which translates to a very long service life.

A longer lifespan directly reduces environmental impact. It minimizes the raw materials, manufacturing energy, and waste associated with producing and disposing of replacement heating elements.

Enabling Cleaner Industrial Processes

MoSi2 elements are critical components in furnaces for industries like glass, ceramics, steel-making, and semiconductors.

By allowing these high-temperature processes to be electrified, they provide a direct pathway for heavy industry to move away from combustion-based heating, significantly reducing its overall carbon footprint.

Understanding the Full Environmental Picture

While operationally clean, a complete assessment requires looking at the entire lifecycle and operational context. Being a trusted advisor means considering the trade-offs.

The Source of Electricity Matters

The single most important factor is the source of your electricity. The environmental benefit of any electric heating system is maximized when it is powered by a clean electricity grid (solar, wind, nuclear, or hydro).

If the electricity is generated from fossil fuels, you are simply shifting the emissions from your facility to the power plant.

Sensitivity to Atmospheric Conditions

MoSi2 elements are not universally applicable. They must be operated in air or inert gas atmospheres.

Using them in the presence of certain reactive gases like hydrogen (H2), chlorine (Cl2), or sulfur dioxide (SO2) will cause rapid degradation and failure. This not only halts production but also creates premature waste.

Manufacturing and End-of-Life

The production of any high-performance material, including MoSi2, is an energy-intensive process. While the long service life offsets much of this initial impact, it is a factor in a full lifecycle analysis. Responsible disposal or recycling at the end of the element's life should also be considered.

Making the Right Choice for Your Application

Ultimately, the decision to use MoSi2 elements should align with your specific technical and environmental goals.

- If your primary focus is reducing on-site emissions: MoSi2 is an excellent choice, as it completely eliminates local combustion byproducts and improves workplace air quality.

- If your primary focus is overall energy efficiency: These elements are highly effective, especially when paired with proper furnace insulation and control systems to leverage their rapid thermal response.

- If your primary focus is operational reliability and lifespan: The long life of MoSi2 minimizes replacement waste, but you must ensure your process atmosphere is compatible to achieve this key benefit.

By understanding these factors, you can confidently leverage MoSi2 technology to achieve both high performance and your environmental objectives.

Summary Table:

| Aspect | Environmental Benefit |

|---|---|

| Emissions | Zero point-of-use emissions, eliminating local pollutants like CO2 and NOx |

| Efficiency | High energy conversion with minimal loss, reducing overall consumption |

| Longevity | Exceptional durability lowers material waste and replacement frequency |

| Applications | Enables electrification in industries like glass, ceramics, and steel-making |

Upgrade to Eco-Friendly High-Temperature Solutions with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in glass, ceramics, steel-making, or semiconductors, our MoSi2 heating elements can help you achieve zero emissions, superior efficiency, and reduced waste. Contact us today to discuss how we can tailor a solution for your environmental and performance goals!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights