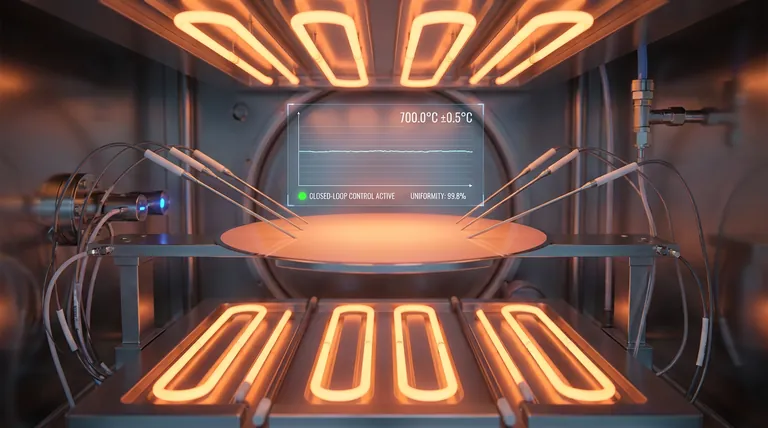

High-precision thermocouples and closed-loop control systems act as the primary stabilizers for film uniformity. By maintaining temperature accuracy within ±0.5 °C, these components ensure heat is distributed evenly across the substrate during Rapid Thermal Processing (RTP). This precise thermal environment forces the nickel silicide reaction to occur simultaneously across the wafer, effectively eliminating localized structural inconsistencies.

The integration of precise sensing and feedback loops transforms the RTP chamber into a uniform reaction environment, ensuring that phase transitions are synchronized across the entire wafer scale rather than being dictated by local thermal gradients.

The Mechanics of Thermal Precision

The Role of Closed-Loop Feedback

In Rapid Thermal Processing, temperature shifts happen in seconds. A closed-loop system continuously monitors the wafer temperature and adjusts the heating elements in real-time.

This constant feedback loop is the only way to maintain stability during rapid ramp-up and hold phases. It ensures that the target temperature is not just reached, but maintained uniformly across the substrate surface.

The Necessity of ±0.5 °C Accuracy

Standard thermocouples often lack the resolution required for advanced semiconductor applications. High-precision thermocouples with a tolerance of ±0.5 °C are essential in this context.

This tight tolerance minimizes the margin of error between the center and the edge of the wafer. It prevents thermal variations that could lead to uneven reaction rates in different zones of the substrate.

Impact on Phase Transitions

Synchronizing the Reaction

The formation of nickel silicide involves specific phase transitions that are highly sensitive to temperature.

When the temperature control is precise, these phase transitions occur in a synchronized manner across the entire wafer. This ensures that the chemical structure of the film is consistent from edge to edge.

Identifying Critical Temperatures

precise increment control allows engineers to pinpoint the exact critical temperatures required for silicidation reactions.

By isolating these specific thermal points, the process window can be optimized to favor the desired silicide phase. This eliminates the guesswork often associated with broader temperature tolerances.

Preventing Common Defects

Eliminating Unreacted Nickel

If heating is non-uniform, certain areas of the wafer may not reach the activation energy required for the reaction.

High-precision control ensures every millimeter of the substrate reaches the target temperature. This prevents the issue of unreacted nickel remaining on the surface after the process is complete.

Avoiding Mixed Phases

Thermal gradients often lead to the formation of non-uniform mixed phases, where different silicide structures coexist in the same film.

By enforcing a uniform thermal profile, the system promotes a single, homogeneous phase. This results in a film with consistent electrical and physical properties throughout.

Understanding the Trade-offs

Dependency on Sensor Calibration

While these systems offer superior uniformity, their performance is entirely dependent on the calibration of the thermocouples.

If the high-precision sensor drifts even slightly, the "precise" feedback loop will actively drive the system to the wrong temperature. Regular, rigorous calibration is required to maintain the ±0.5 °C standard.

Complexity of Tuning

Achieving synchronized phase transitions requires more than just installing high-end hardware; the PID (Proportional-Integral-Derivative) parameters of the control loop must be expertly tuned.

An improperly tuned loop can introduce oscillations, potentially causing more harm to the film structure than a simpler, open-loop system might.

Making the Right Choice for Your Goal

To maximize the quality of your nickel silicide films, align your equipment strategy with your specific processing objectives:

- If your primary focus is Process Development: Leverage the ±0.5 °C precision to identify the exact critical temperatures where phase transitions occur, allowing you to define a robust process window.

- If your primary focus is Yield Improvement: Rely on the closed-loop system's ability to synchronize reactions to eliminate localized defects like unreacted nickel or mixed phase regions.

True uniformity is not achieved by heating the wafer, but by controlling the reaction environment with absolute precision.

Summary Table:

| Component/Feature | Impact on Uniformity | Key Technical Benefit |

|---|---|---|

| High-Precision Thermocouples | Minimizes center-to-edge thermal gradients | Precision within ±0.5 °C tolerance |

| Closed-Loop Control | Real-time adjustment of heating elements | Maintains stability during rapid ramp-up |

| Phase Synchronization | Ensures simultaneous reaction across wafer | Eliminates mixed phases and unreacted Ni |

| Expert PID Tuning | Prevents temperature oscillations | Stabilizes the reaction environment |

Elevate Your Thin Film Precision with KINTEK

Achieving perfect film uniformity requires more than just heat—it demands absolute thermal control. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems engineered for the most demanding semiconductor and lab applications.

Backed by expert R&D and precision manufacturing, our high-temperature furnaces are fully customizable to meet your unique processing needs, ensuring your phase transitions are always synchronized and defect-free.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your custom furnace solution.

References

- V. A. Lapitskaya, Maksim Douhal. Microstructure and Properties of Thin-Film Submicrostructures Obtained by Rapid Thermal Treatment of Nickel Films on Silicon. DOI: 10.3390/surfaces7020013

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the advantage of a high melting point in graphite heating elements? Achieve Extreme Temperatures with Unmatched Stability

- What are the characteristics of aluminum for heating applications? Unlock Efficient Heat Transfer Solutions

- How can the lifespan of the furnace wire be extended? Operate Below Max Temp for Longevity

- Why do MoSi2 heating elements heat up quickly? Discover Their Rapid, Efficient High-Temp Performance

- How does the heating element's electrical resistance affect heat generation? Master Joule Heating for Efficient Thermal Systems

- How do silicon carbide heating elements reduce operating costs? Achieve Long-Term Savings and Efficiency

- Why are industrial K-type thermocouples and mobile data loggers essential? Unlock Precise Quenching Accuracy

- What are the uses of MoSi2 heating elements in ordnance and defense production? Achieve Superior High-Temperature Processing