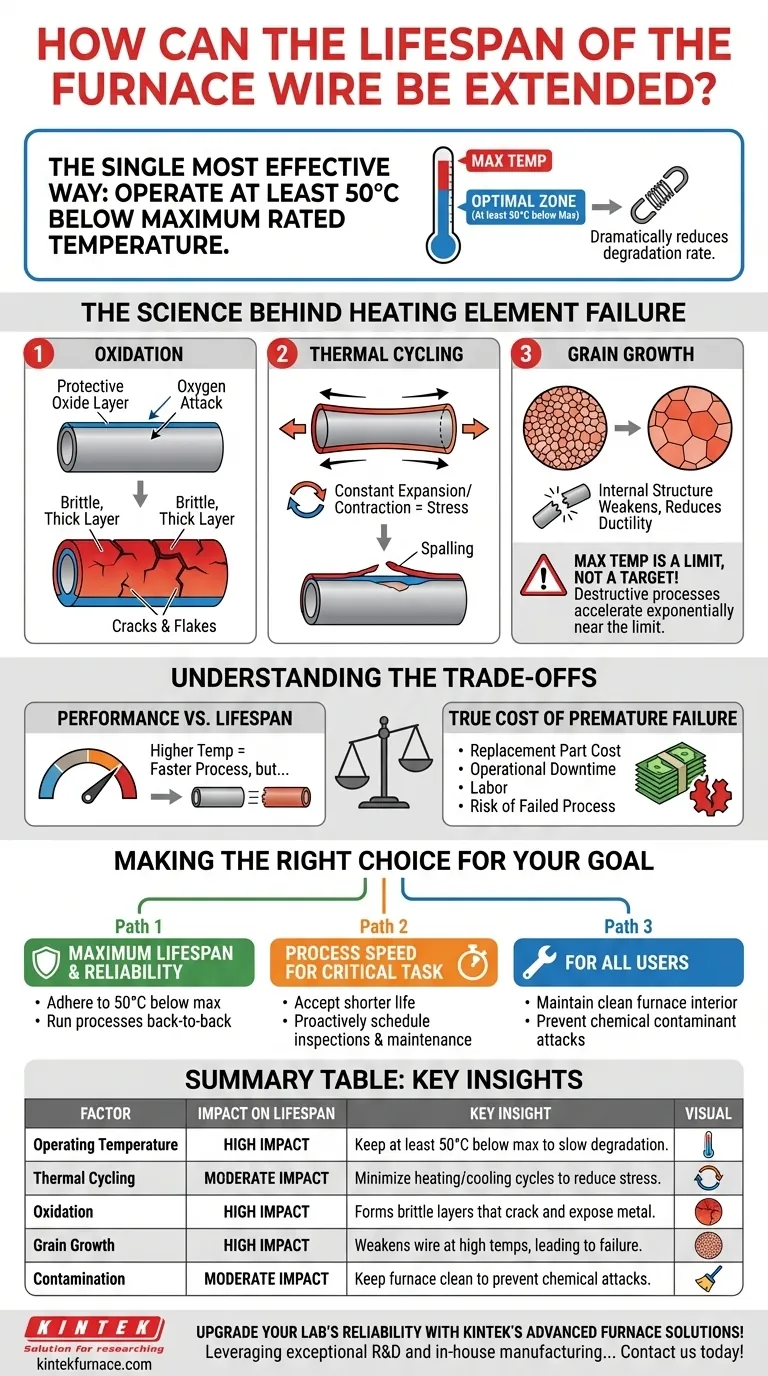

The single most effective way to extend the lifespan of a furnace wire is to operate the furnace at a temperature significantly below its specified maximum. Specifically, running the muffle furnace at least 50°C below its maximum rated temperature dramatically reduces the rate of degradation on the heating elements.

Your furnace's maximum temperature rating is a capability, not a recommended daily operating point. Consistently pushing heating elements to their absolute limit causes accelerated wear and premature failure, while a conservative approach maximizes their service life.

The Science Behind Heating Element Failure

To protect your equipment, you must first understand the forces that work to destroy it. The extreme environment inside a furnace subjects the heating wire to several forms of degradation simultaneously.

The Inevitable Role of Oxidation

At high temperatures, the metal alloy of the furnace wire reacts with oxygen in the air. This forms a thin, protective oxide layer on the wire's surface. While this initial layer is beneficial, repeated heating and cooling causes it to thicken, become brittle, and eventually crack.

The Stress of Thermal Cycling

Every time the furnace heats up and cools down, the wire expands and contracts. This constant physical stress, known as thermal cycling, causes the protective oxide layer to flake off. This process, called spalling, exposes fresh metal underneath, which then oxidizes, and the cycle repeats, progressively thinning the wire until it fails.

Internal Weakening: Grain Growth

At very high temperatures, especially near the maximum rating, the internal crystal structure of the wire's alloy changes. The microscopic grains that make up the metal begin to grow larger, which weakens the wire, reduces its ductility, and makes it more susceptible to breaking under physical stress.

Why "Max Temperature" Is a Limit, Not a Target

The maximum rated temperature is the point at which these destructive processes—oxidation, thermal stress, and grain growth—accelerate exponentially. Operating at or near this limit places the maximum possible stress on the wire, guaranteeing the shortest possible lifespan.

Understanding the Trade-offs

Choosing an operating temperature is a balance between process requirements and equipment longevity. Understanding this trade-off is key to making sound operational decisions.

Performance vs. Lifespan

Running a furnace hotter may speed up your process, but it comes at a direct cost. Each degree you push closer to the maximum limit is a trade-off, sacrificing the heating element's lifespan for a marginal gain in throughput.

The True Cost of Premature Failure

The cost of replacing a furnace wire is more than just the price of the part. It includes the operational downtime, the labor required for the replacement, and the risk of a failed process. These secondary costs often far exceed any perceived benefit from running the furnace at its absolute limit.

Making the Right Choice for Your Goal

Your operational strategy should be dictated by your primary objective. By consciously managing your furnace's temperature, you can align its performance with your goals.

- If your primary focus is maximum equipment lifespan and reliability: Strictly adhere to operating at least 50°C below the rated maximum temperature and, where possible, run processes back-to-back to minimize thermal cycles.

- If your primary focus is process speed for a critical task: Accept that running closer to the maximum temperature will shorten the wire's life and proactively schedule more frequent inspections and maintenance.

- For all users: Always maintain a clean furnace interior, as chemical contaminants can aggressively attack heating elements and accelerate their failure even at moderate temperatures.

Treating your furnace's heating elements with mechanical sympathy is the surest path to reliable and cost-effective operation.

Summary Table:

| Factor | Impact on Lifespan | Key Insight |

|---|---|---|

| Operating Temperature | High impact | Keep at least 50°C below max to slow degradation |

| Thermal Cycling | Moderate impact | Minimize heating/cooling cycles to reduce stress |

| Oxidation | High impact | Forms brittle layers that crack and expose metal |

| Grain Growth | High impact | Weakens wire at high temps, leading to failure |

| Contamination | Moderate impact | Keep furnace clean to prevent chemical attacks |

Upgrade your lab's reliability with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, helping you extend equipment lifespan and reduce downtime. Contact us today to discuss how we can enhance your operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency