At the core of their rapid heating ability is the material's excellent electrical and thermal conductivity. Molybdenum disilicide (MoSi2) is a cermet material that allows electrical current to pass through it with very low resistance, converting that energy into heat with extreme efficiency. This property, combined with its unique ability to withstand immense thermal shock, allows it to reach operating temperatures of over 1700°C in a matter of hours, not days.

MoSi2 elements are engineered for extreme heat, and their rapid heating is a direct result of this design. Their exceptional conductivity allows for swift temperature increases, while a unique self-healing protective layer ensures they can survive the thermal shock and operate effectively where other materials would fail.

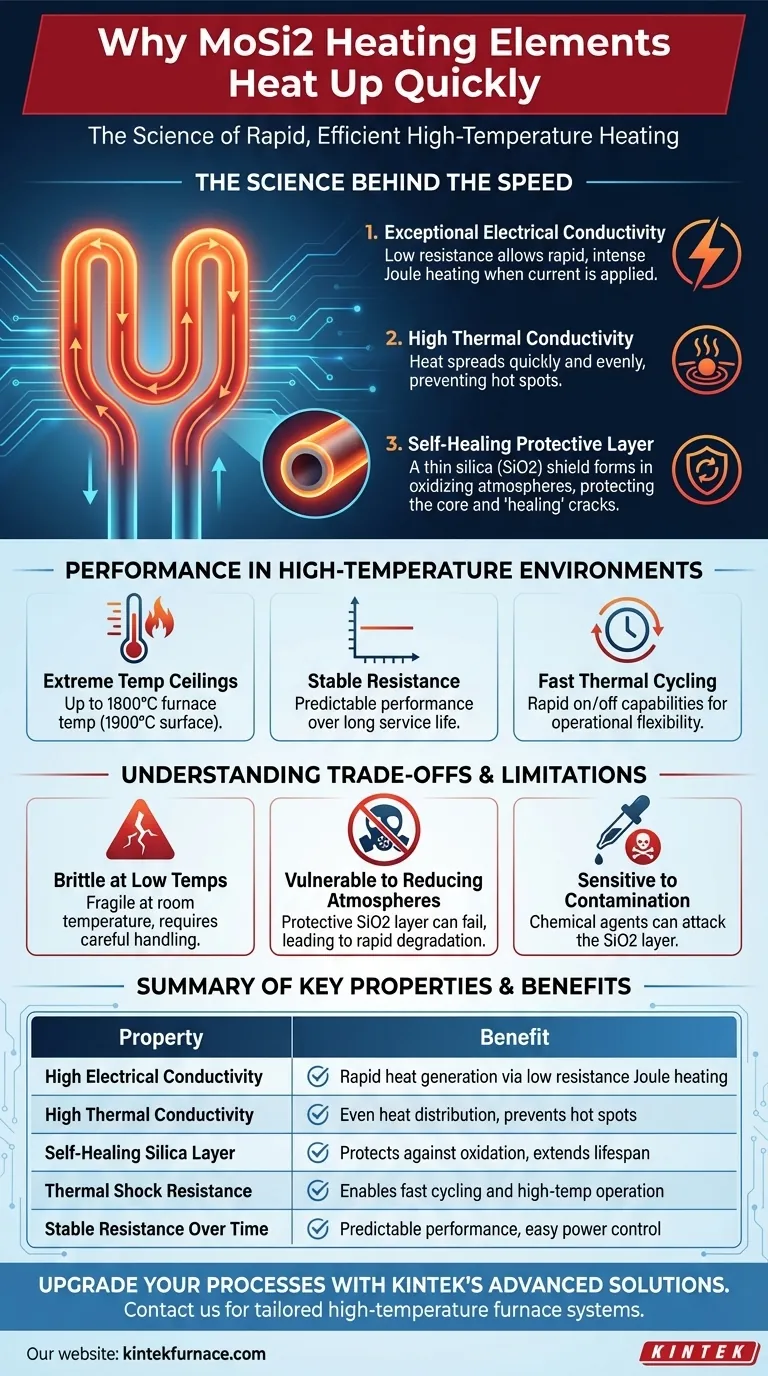

The Science Behind the Speed

To understand why MoSi2 elements outperform many alternatives in heat-up time, we must look at their fundamental material properties. It's a combination of efficient energy conversion and robust high-temperature protection.

Exceptional Electrical Conductivity

MoSi2 possesses a metallic-like electrical conductivity. When a current is applied, the material offers little resistance, causing a rapid and intense generation of heat (Joule heating).

This is fundamentally different from many other heating elements that have higher resistance and therefore heat up more slowly.

High Thermal Conductivity

Once heat is generated, the material's high thermal conductivity ensures it spreads quickly and evenly throughout the element.

This prevents the formation of destructive "hot spots" and contributes to a uniform temperature profile inside the furnace, which is critical for many sensitive processes.

The Self-Healing Protective Layer

The true key to MoSi2's survival at extreme temperatures is the formation of a thin, protective layer of pure silica (SiO2) on its surface when heated in an oxidizing atmosphere.

This glassy layer is what shields the core material from oxidation and degradation. If the layer is cracked or damaged, the underlying material is exposed to oxygen and immediately "heals" the breach by forming a new layer of SiO2.

Performance in High-Temperature Environments

The rapid heating is not just a standalone feature; it's part of a suite of characteristics that make MoSi2 ideal for demanding applications.

Extreme Temperature Ceilings

MoSi2 elements are designed to operate at furnace temperatures up to 1700-1800°C, with the element surface itself reaching as high as 1900°C.

This capability is essential for applications like metal heat treatment, glass melting, and firing high-purity ceramics.

Stable Resistance Over Time

Unlike some elements that increase in resistance as they age (requiring more complex power controllers), MoSi2 maintains a very stable resistance throughout its long service life.

This leads to predictable performance, simplified power control, and the ability to mix new and old elements in the same circuit without issue.

Enabling Fast Thermal Cycling

The combination of rapid heating and robust thermal shock resistance allows furnaces to be cycled on and off much more quickly than with other materials.

This provides significant operational flexibility and energy savings for processes that do not need to run continuously.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. The properties that make MoSi2 so effective also create specific limitations that are critical to understand.

Brittleness at Low Temperatures

Like many ceramic-based materials, MoSi2 is very brittle and fragile at room temperature. It requires careful handling during installation to avoid fractures.

Once it reaches high temperatures (above approximately 1000°C), it becomes more ductile and less susceptible to mechanical shock.

Vulnerability in Reducing Atmospheres

The protective SiO2 layer is the element's lifeline. In reducing or non-oxidizing atmospheres, this layer cannot form or can be chemically stripped away, a process known as spalling.

Without this protective layer, the element will degrade and fail very quickly. Operation in such environments requires specific countermeasures or is simply not recommended.

Sensitivity to Contamination

Certain chemical contaminants can aggressively attack the SiO2 layer, even in an oxidizing atmosphere.

For example, improperly dried paints or colorants on zirconia can release agents that cause premature element failure. Meticulous furnace cleanliness and maintenance are essential.

Making the Right Choice for Your Application

Selecting the correct heating element requires balancing performance needs with operational realities. MoSi2 offers elite performance, but with specific operating requirements.

- If your primary focus is maximum temperature and rapid cycling: MoSi2 is an excellent choice, offering some of the highest operating temperatures and fastest heat-up times available.

- If you are operating in a reducing or chemically reactive atmosphere: You must exercise extreme caution, as MoSi2 elements will degrade quickly without their protective silica layer.

- If your priority is process control and longevity at high temperatures: The stable resistance and self-healing properties of MoSi2 make it a superior long-term investment for compatible applications.

By understanding both the powerful advantages and the specific limitations of MoSi2, you can confidently select the right heating element for your high-temperature process.

Summary Table:

| Property | Benefit |

|---|---|

| High Electrical Conductivity | Rapid heat generation via low resistance Joule heating |

| High Thermal Conductivity | Even heat distribution, prevents hot spots |

| Self-Healing Silica Layer | Protects against oxidation, extends lifespan |

| Thermal Shock Resistance | Enables fast cycling and high-temperature operation |

| Stable Resistance Over Time | Predictable performance, easy power control |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering efficiency, reliability, and superior performance. Contact us today to discuss how our MoSi2 heating elements and other innovations can optimize your operations!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality