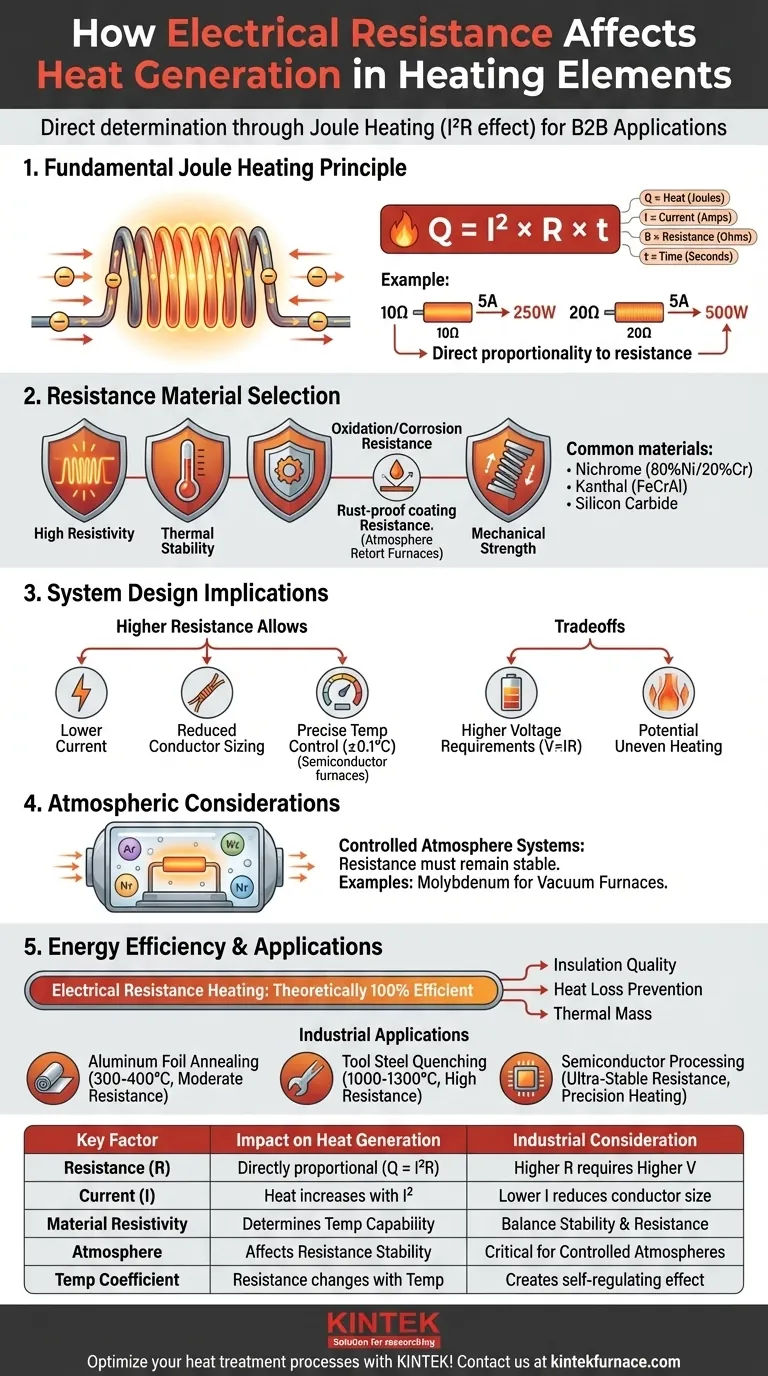

The heating element's electrical resistance directly determines its heat generation capability through Joule heating (I²R effect). Higher resistance leads to greater heat output when current flows, but requires careful balancing with material properties and system design. This principle applies universally across heating systems, from simple ceramic heaters to advanced industrial furnaces like atmosphere retort furnaces. The resistance must be sufficient to generate required temperatures while maintaining energy efficiency and equipment longevity.

Key Points Explained:

-

Fundamental Joule Heating Principle

- Heat generation (Q) follows the formula: Q = I² × R × t

- I = Current (Amperes)

- R = Resistance (Ohms)

- t = Time (Seconds)

- Higher resistance directly increases heat output proportionally to the square of current

- Example: A 10Ω element at 5A produces 250W (5² × 10), while a 20Ω element at same current produces 500W

- Heat generation (Q) follows the formula: Q = I² × R × t

-

Resistance Material Selection Criteria

- Optimal resistance materials must balance:

- High enough resistivity to generate target temperatures

- Thermal stability at operating temperatures

- Oxidation/corrosion resistance (especially critical in atmosphere retort furnaces)

- Mechanical strength under thermal cycling

- Common materials: Nichrome (80%Ni/20%Cr), Kanthal (FeCrAl), silicon carbide

- Optimal resistance materials must balance:

-

System Design Implications

- Higher resistance elements allow:

- Lower current requirements for same heat output

- Reduced conductor sizing in power supply wiring

- More precise temperature control (as seen in ±0.1°C semiconductor furnaces)

- Tradeoffs include:

- Higher voltage requirements (V=IR)

- Potential for uneven heating if resistance isn't uniform

- Higher resistance elements allow:

-

Atmospheric Considerations

- In controlled atmosphere systems:

- Resistance must remain stable despite reactive gases

- Materials like molybdenum used in vacuum furnaces maintain consistent resistance

- Gas composition affects heat transfer efficiency despite identical resistance heating

- In controlled atmosphere systems:

-

Energy Efficiency Factors

- Electrical resistance heating is theoretically 100% efficient (all electricity converts to heat)

- Practical efficiency depends on:

- Insulation quality

- Heat loss prevention (sealed designs in atmosphere furnaces)

- Thermal mass of system components

-

Industrial Applications

- Different processes require specific resistance characteristics:

- Aluminum foil annealing: Moderate resistance for 300-400°C

- Tool steel quenching: High resistance for 1000-1300°C

- Semiconductor processing: Ultra-stable resistance for precision heating

- Different processes require specific resistance characteristics:

Have you considered how the temperature coefficient of resistance affects performance? Most heating elements increase resistance as they heat up, creating a self-regulating effect that must be accounted for in control system design. This becomes particularly important when maintaining precise atmospheres in heat treatment processes.

Summary Table:

| Key Factor | Impact on Heat Generation | Industrial Consideration |

|---|---|---|

| Resistance (R) | Directly proportional to heat output (Q = I²R) | Higher resistance requires higher voltage |

| Current (I) | Heat increases with square of current | Lower current reduces conductor sizing needs |

| Material Resistivity | Determines temperature capability | Must balance thermal stability and oxidation resistance |

| Atmosphere | Affects resistance stability | Critical for vacuum/controlled atmosphere furnaces |

| Temperature Coefficient | Resistance changes with temperature | Creates self-regulating effect in some systems |

Optimize your heat treatment processes with precision-engineered solutions from KINTEK! Our advanced high-temperature furnaces and vacuum systems are designed with precisely calibrated heating elements to deliver unmatched thermal performance. Whether you need standard configurations or fully customized solutions, our in-house R&D and manufacturing capabilities ensure your exact requirements are met.

Contact our thermal engineering experts today to discuss how we can enhance your laboratory or industrial heating applications with our:

- Atmosphere-controlled retort furnaces

- Ultra-high vacuum systems

- Precision rotary kilns

- Customized resistance heating solutions

Products You Might Be Looking For:

View high-vacuum observation windows for furnace monitoring Explore precision vacuum valves for controlled atmosphere systems Discover high-pressure vacuum sintering furnaces See KF flange observation windows for vacuum applications Learn about rotary kilns for material regeneration

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling