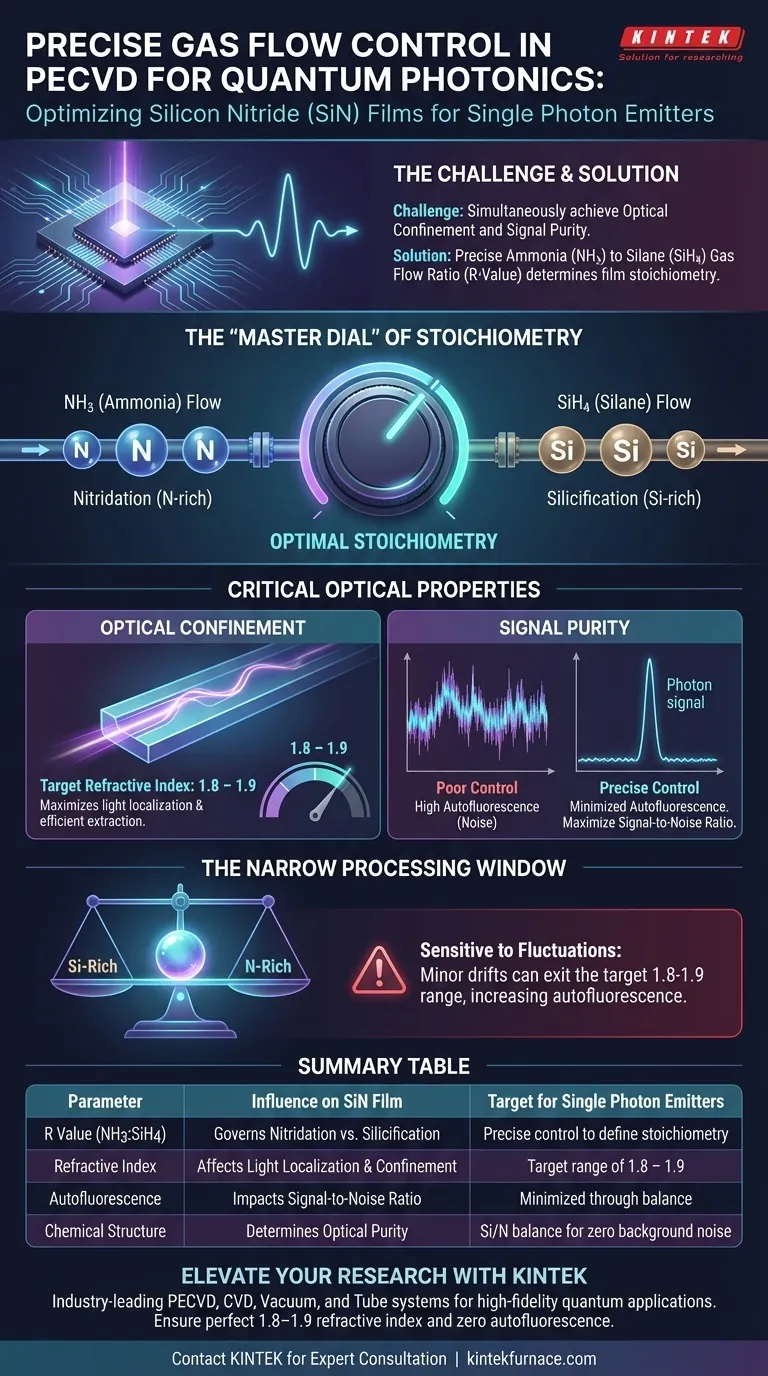

Precise control of the ammonia (NH3) to silane (SiH4) gas flow ratio is the fundamental mechanism for determining the stoichiometry of Silicon Nitride (SiN) films during PECVD. This ratio, often referred to as the R value, directly governs the degree of nitridation or silicification within the film. For single photon emitters, this precision is vital because it simultaneously allows you to tune the refractive index for optical confinement and minimize background fluorescence to ensure signal purity.

The gas flow ratio acts as a master dial for film composition, balancing chemical structure to achieve a specific refractive index (1.8–1.9) while suppressing autofluorescence to maximize the signal-to-noise ratio.

The Mechanics of Stoichiometry

Defining the R Value

In Plasma-Enhanced Chemical Vapor Deposition (PECVD), the relative abundance of reactant gases is not merely about supply; it is about chemical structure. The R value is the explicit ratio of ammonia flow to silane flow.

Nitridation vs. Silicification

Modifying this ratio shifts the film's composition along a spectrum. A higher ammonia flow promotes nitridation, resulting in nitrogen-rich films. Conversely, a higher silane flow increases silicification, leading to silicon-rich films. This chemical balance is the root cause of all subsequent optical behaviors.

Critical Optical Properties for Single Photon Emitters

Optimizing Light Localization

For single photon emitters, the ability to confine and guide light is paramount. This capability relies heavily on the material's refractive index.

By strictly regulating the gas flow ratio, you can fine-tune the refractive index to a target range of 1.8 to 1.9. This specific range is necessary to enhance light localization, ensuring efficient photon extraction and direction.

Ensuring Signal Purity

The most significant challenge in single photon detection is distinguishing the target photon from background noise.

Improper stoichiometry can lead to background autofluorescence, where the film itself emits light that obscures the signal. Precise flow control minimizes this background noise, thereby improving the signal-to-noise ratio and the purity of the detected single photons.

Understanding the Trade-offs

The Balance of Composition

There is often a narrow processing window to achieve optimal results.

Pushing the ratio too far toward silicification might increase the refractive index, but it risks altering the electronic band structure in a way that introduces optical losses or unwanted fluorescence.

Sensitivity to Fluctuations

Because the relationship between the R value and optical properties is direct, even minor fluctuations in mass flow controllers can lead to inconsistent film quality.

If the ratio drifts, the refractive index may exit the 1.8–1.9 target window, or autofluorescence may rise unexpectedly, rendering the device unsuitable for high-fidelity quantum applications.

Making the Right Choice for Your Goal

To maximize the performance of your single photon emitters, prioritize the stability of your gas delivery system.

- If your primary focus is Optical Confinement: Target a gas ratio that strictly maintains the refractive index between 1.8 and 1.9 to maximize light localization.

- If your primary focus is Detection Sensitivity: Prioritize a stoichiometry that minimizes the "degree of silicification" or "nitridation" associated with high autofluorescence to protect the signal-to-noise ratio.

Ultimately, the gas flow ratio is the bridge between raw chemical inputs and the high-precision optical performance required for quantum photonics.

Summary Table:

| Parameter | Influence on SiN Film | Target for Single Photon Emitters |

|---|---|---|

| R Value (NH3:SiH4) | Governs Nitridation vs. Silicification | Precise control to define film stoichiometry |

| Refractive Index | Affects Light Localization & Confinement | Target range of 1.8 – 1.9 |

| Autofluorescence | Impacts Signal-to-Noise Ratio | Minimized through stoichiometric balance |

| Chemical Structure | Determines Optical Purity | Silicon/Nitrogen balance for zero background noise |

Elevate Your Quantum Photonic Research with KINTEK

Precise gas control is the difference between a high-fidelity signal and background noise. KINTEK provides industry-leading PECVD systems and high-temp lab furnaces designed for the rigorous demands of Silicon Nitride film deposition. Backed by expert R&D and manufacturing, our equipment—including CVD, Vacuum, and Tube systems—is fully customizable to ensure your single photon emitters achieve the perfect 1.8–1.9 refractive index and zero autofluorescence.

Ready to optimize your thin-film stoichiometry?

Contact KINTEK today for expert consultation

Visual Guide

References

- Zachariah O. Martin, Vladimir M. Shalaev. Single-photon emitters in PECVD-grown silicon nitride films: from material growth to photophysical properties. DOI: 10.1515/nanoph-2024-0506

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What are the key advantages of the PECVD process? Unlock Low-Temp, High-Speed Film Deposition

- How does the deposition rate of PECVD compare to PVD? Uncover Key Differences for Your Lab

- What role does PECVD play in creating optical coatings? Achieve Precision Thin Films for Enhanced Optics

- What is the deposition rate difference between PECVD and CVD? Uncover the Best Method for Your Thin Films

- What are the main applications of PECVD technology? Discover Versatile Thin-Film Solutions for Modern Industries

- What is the role of LPCVD in acm-BN synthesis? Master Phase Transitions with Precise Thermal Control

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings