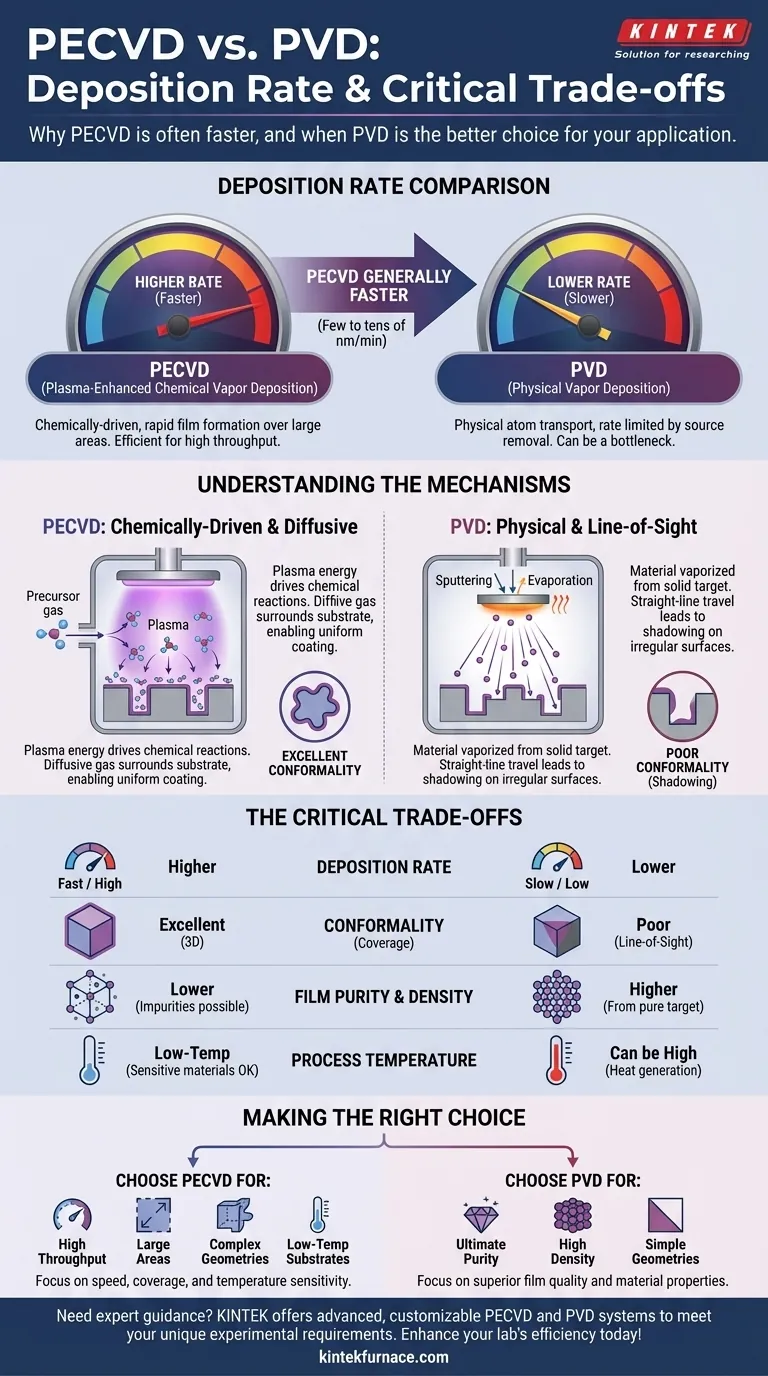

Generally, PECVD offers higher deposition rates than PVD. This is because Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a chemically-driven process that can form films more rapidly over large areas, making it highly efficient for applications where throughput is a key manufacturing metric.

While PECVD is typically faster, the choice between it and Physical Vapor Deposition (PVD) is not just about speed. The decision hinges on a critical trade-off between PECVD's high rate and excellent surface coverage versus PVD's superior film purity and density.

Understanding the Core Mechanisms

To understand the difference in rates, we must first look at how each process fundamentally works. The mechanism dictates the speed, quality, and application of the resulting film.

PECVD: A Chemically-Driven Process

PECVD is a type of Chemical Vapor Deposition. It uses an electric field to create low-temperature plasma, which provides the energy needed to drive chemical reactions.

Precursor gases are introduced into a vacuum chamber, and the plasma breaks them down. These reactive chemical species then deposit onto the substrate, forming a solid film. The process is diffusive, meaning the reactive gas surrounds the substrate.

The deposition rate in PECVD can be actively controlled by increasing the plasma power or the flow rate of the precursor gas, which accelerates the chemical reactions.

PVD: A Line-of-Sight Physical Process

Physical Vapor Deposition works by vaporizing material from a solid source (a "target") and having it condense on the substrate. This is a purely physical mechanism.

The two main types are sputtering (bombarding the target with ions) and evaporation (heating the target until it vaporizes).

Crucially, PVD is a line-of-sight process. The vaporized atoms travel in a straight line from the target to the substrate, much like a spray-paint can.

A Direct Comparison of Deposition Rate

While process parameters for specific materials can vary, a general comparison highlights PECVD's advantage in speed for many common applications.

Why PECVD is Often Faster

The chemical reaction in PECVD can be scaled very effectively. By supplying more precursor gas and plasma energy, you can generate a high concentration of reactive species throughout the chamber, allowing for rapid film growth across a large surface.

PVD's rate is limited by the efficiency of physically removing and transporting atoms from the target. This can become a bottleneck, especially when trying to coat large or complex surfaces uniformly.

Typical Rate Ranges

While exact numbers depend on the material and equipment, PECVD rates often fall in the range of a few to tens of nanometers per minute.

This rate is highly effective for industrial-scale production where coating time per substrate is a critical cost factor.

Understanding the Trade-offs Beyond Speed

A faster deposition rate is not always better. The fundamental differences between the processes create critical trade-offs in film quality and application suitability.

Film Quality and Conformality

This is a major differentiator. Because PECVD is a gas-driven, diffusive process, it provides excellent conformality. It can evenly coat complex 3D surfaces, including trenches and sidewalls.

PVD's line-of-sight nature results in poor conformality. Areas not directly facing the source receive little to no coating, creating "shadowing" effects on irregular surfaces.

Temperature and Substrate Compatibility

PECVD is a low-temperature process. The use of plasma provides the reaction energy, so the substrate itself does not need to be heated to high temperatures. This makes PECVD ideal for coating temperature-sensitive materials like plastics or polymers.

PVD processes, particularly sputtering, can generate significant heat at the substrate surface, limiting their use with sensitive materials.

Film Purity and Density

PVD generally produces films with higher purity and density. The material is transferred directly from a high-purity solid target to the substrate with minimal contamination.

PECVD films can contain impurities from the precursor gases, such as incorporated hydrogen. This can result in a less dense film with different mechanical or optical properties compared to a PVD equivalent.

Making the Right Choice for Your Application

Selecting the correct deposition method requires matching the process strengths to your project's primary goal.

- If your primary focus is high throughput and large-area coating: PECVD is often the superior choice due to its generally higher deposition rates.

- If your primary focus is coating complex 3D geometries: PECVD's excellent conformality makes it the clear winner over line-of-sight PVD.

- If your primary focus is ultimate film purity and density: PVD is typically preferred, as it directly transfers material from a pure solid source.

- If your primary focus is coating temperature-sensitive materials: PECVD's lower operating temperatures give it a significant advantage.

Ultimately, selecting the right method requires evaluating your specific needs for speed, coverage, temperature sensitivity, and final film properties.

Summary Table:

| Aspect | PECVD | PVD |

|---|---|---|

| Deposition Rate | Higher (few to tens of nm/min) | Lower |

| Process Type | Chemically-driven, diffusive | Physical, line-of-sight |

| Conformality | Excellent for 3D surfaces | Poor due to shadowing |

| Film Purity/Density | Lower, may have impurities | Higher, from pure solid target |

| Temperature | Low-temperature, suitable for sensitive materials | Can generate heat, less suitable |

| Best For | High throughput, large areas, complex geometries | High purity, dense films |

Need expert guidance on choosing the right deposition method for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including PECVD and PVD systems. Our product line—featuring Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition