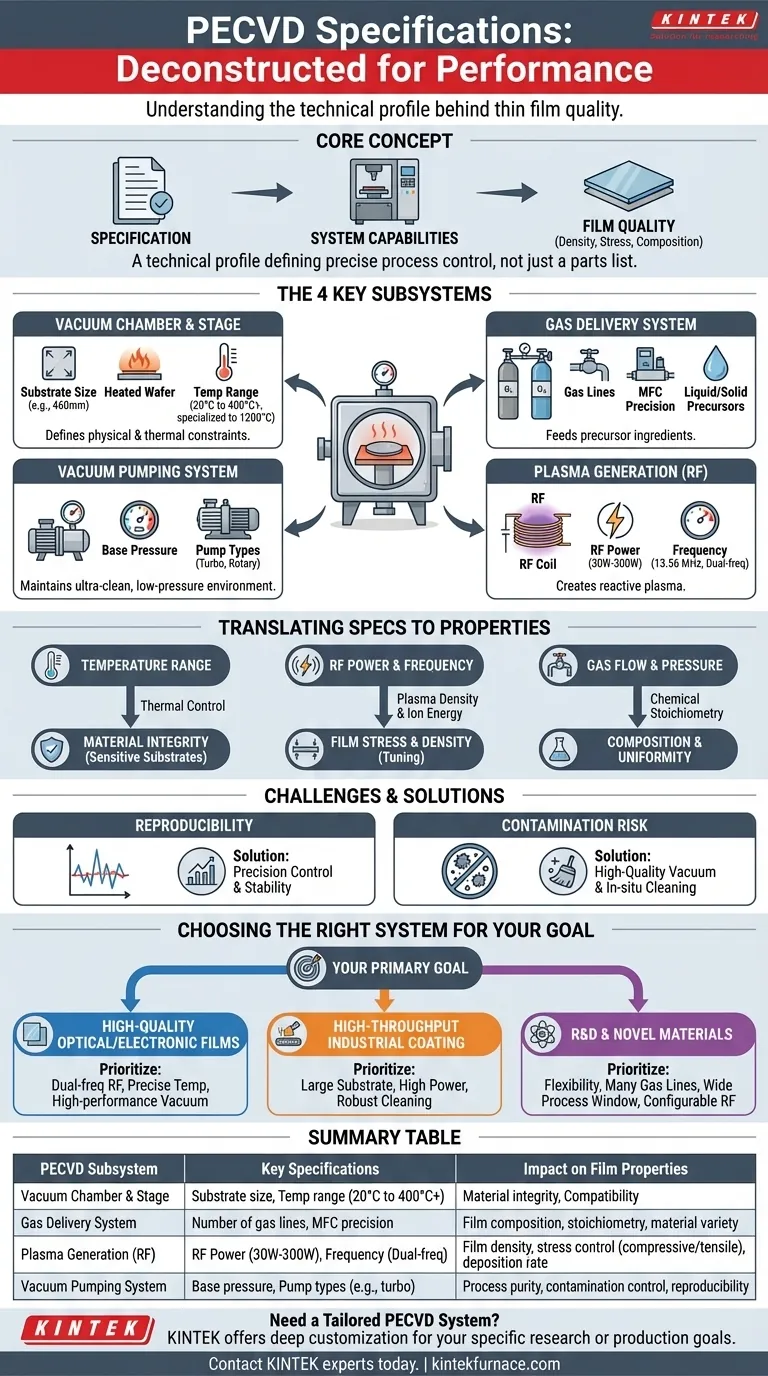

At its core, a Plasma-Enhanced Chemical Vapor Deposition (PECVD) specification is not a single document but a detailed technical profile of the system's capabilities. These specifications define the hardware components, the range of controllable process parameters, and ultimately, the types of thin films the machine can produce and at what quality.

A PECVD system's specifications are a direct reflection of its purpose. They move beyond a simple list of parts to describe the precise control the system offers over the deposition environment, which is the critical factor in determining the final properties—such as density, stress, and chemical composition—of the deposited film.

Deconstructing PECVD Specifications: Core Components and Process Variables

To understand a PECVD system, you must break down its specifications into four fundamental subsystems. Each one provides a critical set of "control knobs" for the deposition process.

The Vacuum Chamber and Substrate Stage

This is the physical environment where the deposition occurs. Its specifications define the physical constraints and thermal conditions of the process.

Key specs include the substrate size (e.g., handling for up to 460mm wafers) and the stage temperature range. A typical range is 20°C to 400°C, but specialized systems can reach 1200°C. Precise temperature control is paramount.

The Gas Delivery System

This system feeds the precursor "ingredients" into the chamber. Its sophistication dictates the variety and complexity of films you can create.

Look for the number of gas lines, which determines how many different gases can be used. These are controlled by Mass Flow Controllers (MFCs) for precision. Systems may also support liquid or solid precursors, expanding their material capabilities far beyond standard gases like silane (SiH₄) and ammonia (NH₃).

The Plasma Generation System

This is the heart of the PECVD process. It creates the reactive plasma that enables deposition at low temperatures.

Specifications center on the RF (Radio Frequency) generator. Critical parameters include power (e.g., 30W to 300W) and frequency. Many systems use a standard 13.56 MHz frequency, but advanced tools feature dual-frequency (RF and LF) or multi-frequency capabilities for fine-tuning film properties.

The Vacuum Pumping System

This system creates and maintains the ultra-clean, low-pressure environment necessary for deposition.

Its performance is defined by the pump types (typically a turbo-molecular pump backed by a rotary vane pump) and its ability to reach a low base pressure. A low base pressure, indicated by high compression ratios for gases like N₂, ensures a pure environment free from contaminants before the process begins.

How Specifications Translate to Film Properties

The hardware specifications are only meaningful when you understand how they influence the final thin film. Each parameter is a lever to control a specific material property.

Temperature Control for Material Integrity

The specified temperature range is a primary feature of PECVD. The ability to deposit films at low temperatures (e.g., < 400°C) is what allows for processing on temperature-sensitive substrates like polymers or pre-processed semiconductor wafers without causing damage.

RF Power and Frequency for Film Stress and Density

RF power directly influences the plasma density and ion bombardment energy, which in turn affects the deposition rate and the physical density of the film.

More importantly, frequency control is the primary tool for managing film stress. Systems with dual-frequency (e.g., high-frequency RF and low-frequency LF) capabilities allow operators to deposit dense films while precisely tuning the internal stress from compressive to tensile, which is critical for preventing cracking and ensuring mechanical stability.

Gas Flow and Pressure for Composition and Uniformity

The precision of the Mass Flow Controllers (MFCs) and the stability of the chamber pressure directly determine the chemical composition and stoichiometry of the film.

These parameters, along with the chamber and electrode geometry, are also essential for achieving uniform film thickness across the entire surface of the substrate.

Understanding the Trade-offs and Limitations

While powerful, PECVD technology is not without its challenges. Understanding these limitations is key to interpreting a system's specifications realistically.

The Challenge of Reproducibility

The primary limitation of PECVD is maintaining stable and perfectly reproducible deposition conditions. Small fluctuations in gas flow, pressure, temperature, or RF power can lead to variations in film properties.

This is why high-end specifications emphasize precision control and stability in all subsystems. A system with tight control specifications is better equipped to deliver consistent results run after run.

The Risk of Contamination

PECVD chambers are highly susceptible to contamination from atmospheric leaks, residual gases, or impurities from previous runs. This can severely degrade film quality.

Therefore, specifications for a high-quality vacuum system (low base pressure) and the availability of in-situ plasma cleaning with endpoint control are not just features—they are necessities for reliable, high-performance operation.

Making the Right Choice for Your Goal

The "best" PECVD specifications are entirely dependent on your application. Use your primary goal to prioritize which parameters matter most.

- If your primary focus is high-quality, low-stress optical or electronic films: Prioritize systems with dual-frequency RF for stress control, a wide and precise temperature range, and a high-performance vacuum system for ultimate purity.

- If your primary focus is high-throughput industrial coating (e.g., barrier layers): Prioritize specifications for large substrate handling, high deposition rates (enabled by higher power), and robust in-situ cleaning to maximize uptime.

- If your primary focus is R&D and novel material exploration: Prioritize flexibility, including a large number of gas lines for different precursors, a wide process window (pressure, power, temperature), and configurable RF options.

Ultimately, matching the technical specifications of the tool to the required properties of your final material is the key to success.

Summary Table:

| PECVD Subsystem | Key Specifications | Impact on Film Properties |

|---|---|---|

| Vacuum Chamber & Stage | Substrate size, Temperature range (e.g., 20°C to 400°C+) | Material integrity, Compatibility with sensitive substrates |

| Gas Delivery System | Number of gas lines, Mass Flow Controller (MFC) precision | Film composition, stoichiometry, material variety |

| Plasma Generation (RF) | RF Power (e.g., 30W-300W), Frequency (e.g., 13.56 MHz, dual-frequency) | Film density, stress control (compressive/tensile), deposition rate |

| Vacuum Pumping System | Base pressure, Pump types (e.g., turbo-molecular) | Process purity, contamination control, reproducibility |

Need a PECVD System Tailored to Your Specific Research or Production Goals?

Interpreting specifications is the first step; acquiring a system that perfectly matches your unique requirements for thin-film stress, composition, and throughput is the next. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced PECVD solutions. Our strong deep customization capability ensures the system—whether a standard model or a fully customized design—is engineered to precisely meet your experimental and production challenges.

Let's discuss your project. Contact our experts today to explore how our PECVD systems can deliver the precise film properties your work demands.

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition