Controlling the quality of a PECVD film hinges on five primary process parameters. These are the gas flow rates and composition, plasma power, chamber pressure, substrate temperature, and deposition time. Manipulating these variables gives you direct control over the plasma chemistry and surface reactions, which in turn dictate the final film's density, stress, chemical makeup, and electrical performance.

PECVD film quality is not about optimizing a single parameter, but about balancing competing forces. The interplay between gas composition, plasma energy, and substrate temperature determines the final microstructure and properties of the deposited material.

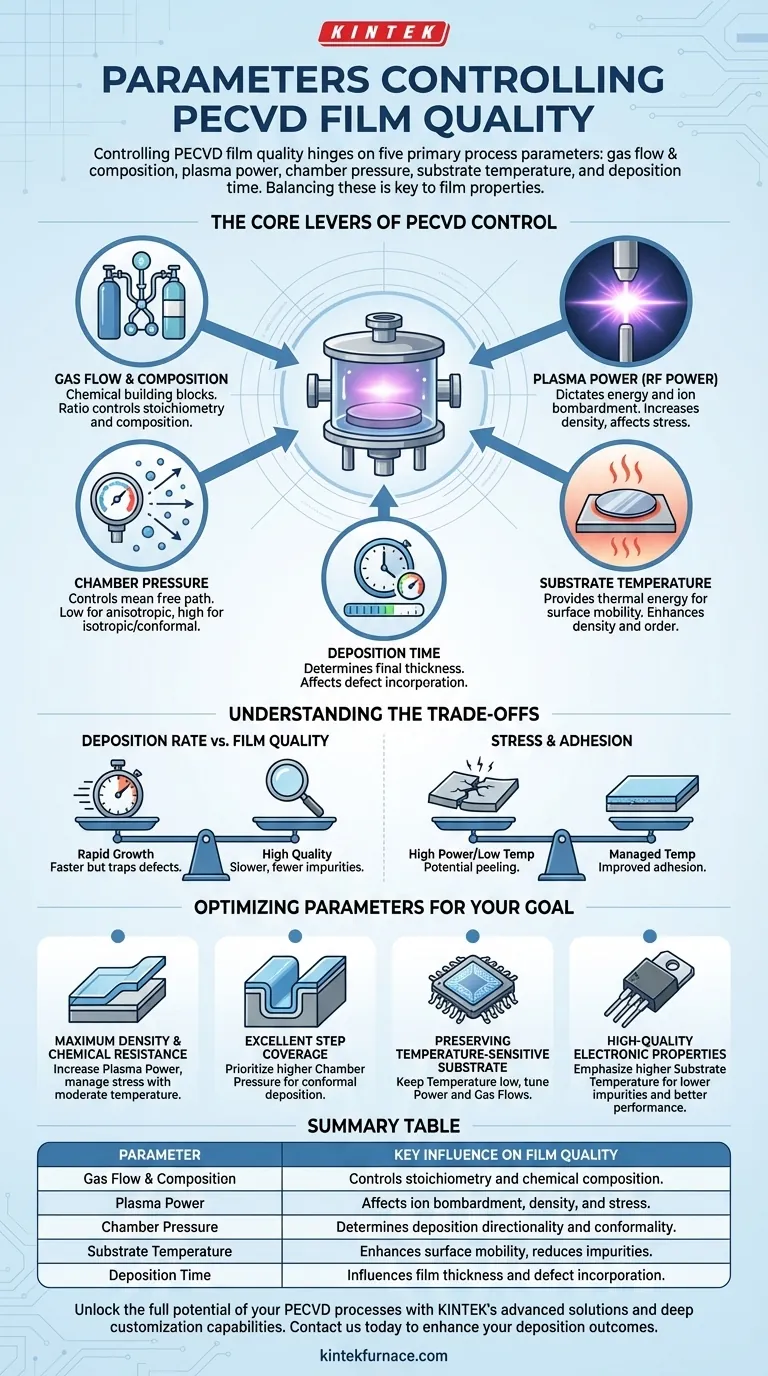

The Core Levers of PECVD Control

To achieve a specific film property, you must understand how each process parameter influences the deposition environment. These parameters are not independent knobs; changing one often requires adjusting others to maintain a stable process.

Gas Flow and Composition

The gases introduced into the chamber are the chemical building blocks of your film. The flow rate of each precursor gas determines the availability of reactants for the plasma.

More importantly, the ratio of different gases (e.g., silane to nitrous oxide for silicon dioxide) directly controls the film's stoichiometry and chemical composition. An incorrect ratio can lead to off-spec, unstable films.

Plasma Power (RF Power)

Plasma power dictates the energy within the chamber. Higher power increases the dissociation of precursor gases, creating a more reactive chemical environment.

This also increases the energy of ion bombardment onto the substrate. This physical action can compact the growing film, increasing its density and mechanical hardness. However, excessive power can induce stress and damage the substrate.

Chamber Pressure

Pressure controls the mean free path of particles—the average distance a molecule travels before colliding with another.

At low pressure, particles travel in straighter lines, leading to more directional, or anisotropic, deposition. At high pressure, more collisions occur, resulting in a more uniform, or isotropic, deposition that is better at coating complex 3D features (conformal coverage).

Substrate Temperature

Temperature provides thermal energy to the atoms and molecules arriving at the substrate surface. This energy enhances their surface mobility, allowing them to settle into more stable, lower-energy positions.

Higher temperatures generally produce denser, more ordered films with lower intrinsic stress and fewer incorporated impurities like hydrogen. This leads to superior electrical and optical properties.

The Role of Ion Bombardment

Generated by the plasma, energetic ion bombardment is a defining characteristic of PECVD. It is not an independent parameter but a direct consequence of plasma power and pressure.

This physical bombardment physically compacts the film as it grows, which helps increase density, improve adhesion, and remove contaminants. In high-density plasma processes, this effect can be strong enough to cause sputtering, which can be leveraged to fill deep trenches or holes without voids.

Understanding the Trade-offs

Optimizing a PECVD process is always a matter of balancing competing factors. Improving one film property often comes at the expense of another.

Deposition Rate vs. Film Quality

Increasing plasma power and chamber pressure can significantly speed up the deposition rate. However, this rapid growth often traps defects and impurities, leading to higher film stress and inferior electrical or optical performance. A slower, more controlled deposition generally yields higher quality.

Stress and Adhesion

Aggressive deposition conditions, particularly high plasma power and low temperature, can create high compressive or tensile stress in the film. This stress can cause the film to crack or even peel off the substrate (delamination). Temperature is a critical tool for managing and annealing stress during growth.

Conformal Coverage vs. Density

Achieving a highly conformal coating on a complex surface often requires higher pressure. However, the increased scattering at high pressure can reduce the energy of ion bombardment, potentially leading to a less dense film compared to a low-pressure, directional process.

Temperature Limitations

While higher temperatures produce better films, the substrate itself may have a strict thermal budget. The primary advantage of PECVD is its ability to deposit high-quality films at low temperatures (typically 200-400°C), but this is a trade-off against the even higher quality achievable with high-temperature techniques like LPCVD.

Optimizing Parameters for Your Goal

Your choice of process parameters should be driven by the intended application of the film. There is no single "best" recipe; there is only the best recipe for your specific goal.

- If your primary focus is maximum density and chemical resistance (e.g., for a barrier layer): Emphasize higher ion energy by increasing plasma power while carefully managing stress with moderate temperature.

- If your primary focus is excellent step coverage on complex topography: Prioritize higher chamber pressure to reduce the mean free path and promote more isotropic, conformal deposition.

- If your primary focus is preserving a temperature-sensitive substrate: Leverage PECVD's core advantage by keeping temperature low and compensating by carefully tuning plasma power and gas flows to achieve the required film properties.

- If your primary focus is high-quality electronic properties (e.g., for an insulator like SiO₂): Emphasize higher substrate temperature to enhance surface mobility and drive out impurities, creating a more stable and less leaky film.

Ultimately, mastering PECVD is an exercise in systematically manipulating these interconnected variables to achieve a specific, desired material outcome.

Summary Table:

| Parameter | Key Influence on Film Quality |

|---|---|

| Gas Flow & Composition | Controls stoichiometry and chemical composition |

| Plasma Power | Affects ion bombardment, density, and stress |

| Chamber Pressure | Determines deposition directionality and conformality |

| Substrate Temperature | Enhances surface mobility, reduces impurities |

| Deposition Time | Influences film thickness and defect incorporation |

Unlock the full potential of your PECVD processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD Systems, tailored to your unique needs. Our deep customization capabilities ensure precise control over film quality parameters. Contact us today to discuss how we can enhance your deposition outcomes and drive innovation in your research or production.

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films