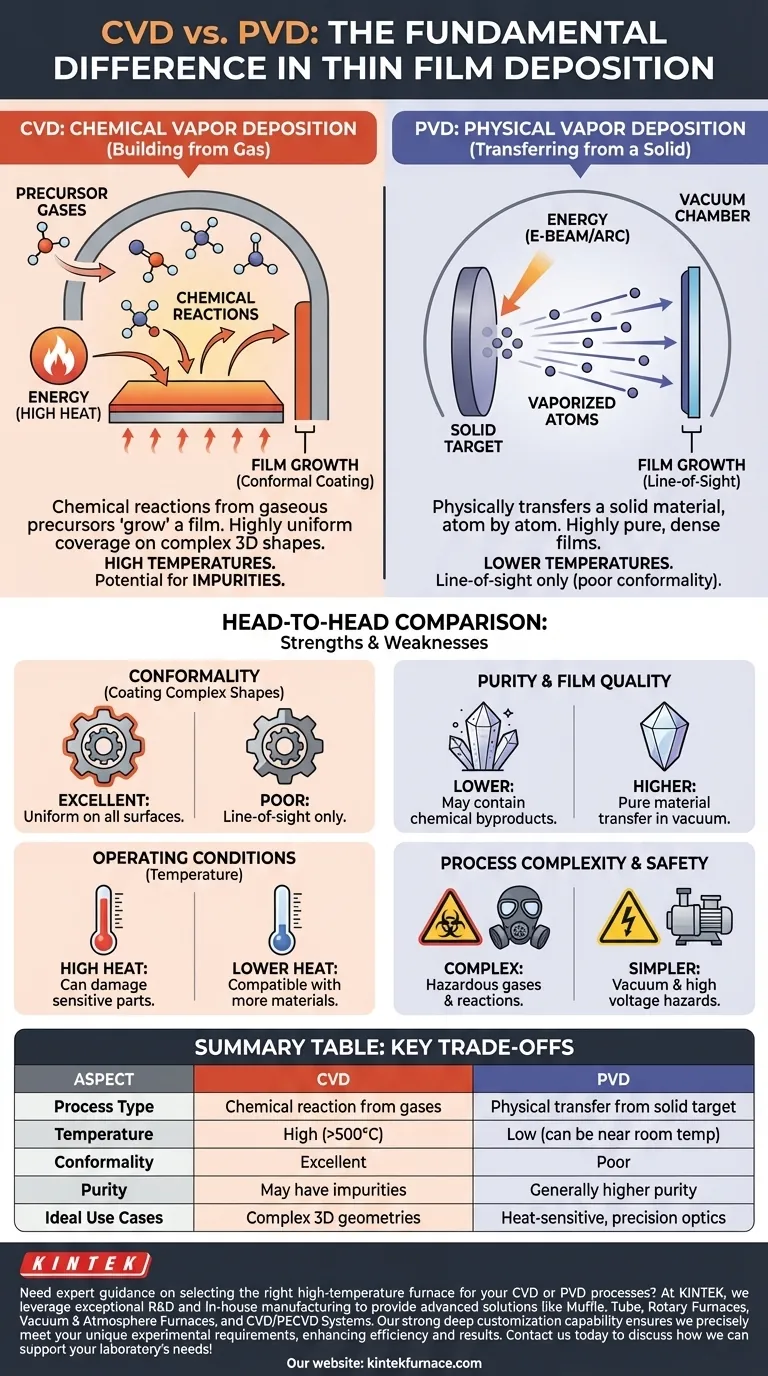

At its core, the difference between chemical vapor deposition (CVD) and physical vapor deposition (PVD) lies in how the coating material arrives at the substrate. CVD uses chemical reactions from gaseous precursors to "grow" a film on the surface, while PVD physically transfers a solid material, atom by atom, onto the surface in a vacuum. This distinction dictates everything from the quality of the coating to the types of parts that can be successfully coated.

The central decision between CVD and PVD is a trade-off. CVD provides superior, uniform coverage on complex, three-dimensional shapes, whereas PVD excels at producing highly pure, dense films at lower temperatures, making it ideal for precision optics or heat-sensitive components.

The Fundamental Divide: Chemical vs. Physical

To choose the right method, you must first understand the fundamental process of each. One builds a film through a chemical synthesis, while the other moves it through a physical transfer.

How CVD Works: Building from Gas

In chemical vapor deposition, volatile precursor gases are introduced into a reaction chamber containing the substrate.

Energy, typically in the form of high heat, is applied to the chamber. This energy initiates chemical reactions among the gases.

These reactions cause a new, solid material to form and deposit uniformly onto the heated substrate, creating the thin film. Think of it like condensation forming on a cold glass, but instead of water vapor, it's a chemical reaction producing a solid film on a hot surface.

A common variant is Plasma-Enhanced CVD (PECVD), which uses plasma instead of just heat. This allows the process to run at much lower temperatures, making it suitable for substrates that can't withstand intense heat.

How PVD Works: Transferring from a Solid

In physical vapor deposition, the process begins with a solid source material, known as the "target," inside a high-vacuum chamber.

Energy (like an electron beam or an arc) is used to bombard this target, vaporizing it and ejecting material atom by atom.

These atoms travel in a straight line through the vacuum and physically condense onto the cooler substrate, building up the thin film. This is a "line-of-sight" process, much like spray painting.

A Head-to-Head Comparison

The differences in their fundamental mechanisms lead to very different strengths, weaknesses, and ideal use cases.

Conformality: Coating Complex Shapes

CVD excels here. Because the precursor gases flow around the entire part, the resulting chemical reaction and deposition occur on all exposed surfaces simultaneously. This creates a highly conformal coating that is uniform even inside deep trenches or on complex 3D geometries.

PVD struggles with this. As a line-of-sight process, it can only coat surfaces that are directly visible from the source material's location. This makes it very difficult to achieve uniform coverage on intricate shapes, often leaving "shadowed" areas uncoated.

Purity and Film Quality

PVD generally produces films with higher purity. The process simply moves material from a pure solid source to the substrate in a clean vacuum environment, with no chemical byproducts to manage.

CVD films can sometimes contain impurities. These are byproducts from the chemical reactions that can become trapped within the growing film. The process also requires extremely pure precursor gases to avoid contamination.

Operating Conditions: Temperature and Environment

Traditional CVD is a high-temperature process, often operating at several hundred or even over a thousand degrees Celsius to drive the necessary chemical reactions. This can damage or deform heat-sensitive substrates.

PVD can often be performed at much lower temperatures, sometimes close to room temperature. This makes it compatible with a wider range of materials, including plastics and other sensitive components.

Process Complexity and Safety

PVD is often considered mechanically simpler, though it requires sophisticated high-vacuum equipment. The primary hazards relate to high voltages and handling the vacuum systems.

CVD is chemically more complex. It involves handling volatile, and often toxic or flammable, precursor gases, which requires stringent safety protocols and exhaust management systems.

Understanding the Trade-offs

Neither method is universally superior; the correct choice depends entirely on balancing their inherent limitations against your project goals.

The Downside of CVD: High Heat and Byproducts

The primary limitation of traditional CVD is its high operating temperature, which restricts the types of substrates you can use. Furthermore, managing the chemical byproducts of the reaction is essential to prevent film contamination and ensure safety.

The Limitation of PVD: Line-of-Sight Deposition

PVD's biggest weakness is its inability to conformally coat complex geometries. If you need a uniform film on all sides of a non-flat object, PVD is often a poor choice unless the part can be rotated and manipulated during deposition, which adds complexity and cost.

Making the Right Choice for Your Goal

Your application's specific requirements should dictate your choice between these two powerful technologies.

- If your primary focus is coating complex 3D parts or internal surfaces: Choose CVD for its unparalleled conformality.

- If your primary focus is the highest possible purity or coating heat-sensitive materials: Choose PVD for its clean, low-temperature process.

- If your primary focus is creating a dense, highly adherent, and wear-resistant film for precision tools or optics: PVD is often the industry standard due to superior film properties.

- If your primary focus is versatility across many material types and achieving uniform coatings is paramount: CVD, especially with variants like PECVD, offers a broad operational window.

Understanding this fundamental difference between a chemical reaction and a physical transfer is the key to selecting the ideal deposition technology for your specific engineering challenge.

Summary Table:

| Aspect | CVD | PVD |

|---|---|---|

| Process Type | Chemical reaction from gases | Physical transfer from solid target |

| Temperature | High (often >500°C) | Low (can be near room temperature) |

| Conformality | Excellent for 3D shapes | Poor, line-of-sight only |

| Purity | May have impurities | Generally higher purity |

| Ideal Use Cases | Complex geometries, uniform coverage | Heat-sensitive materials, precision optics |

Need expert guidance on selecting the right high-temperature furnace for your CVD or PVD processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and results. Contact us today to discuss how we can support your laboratory's needs!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition