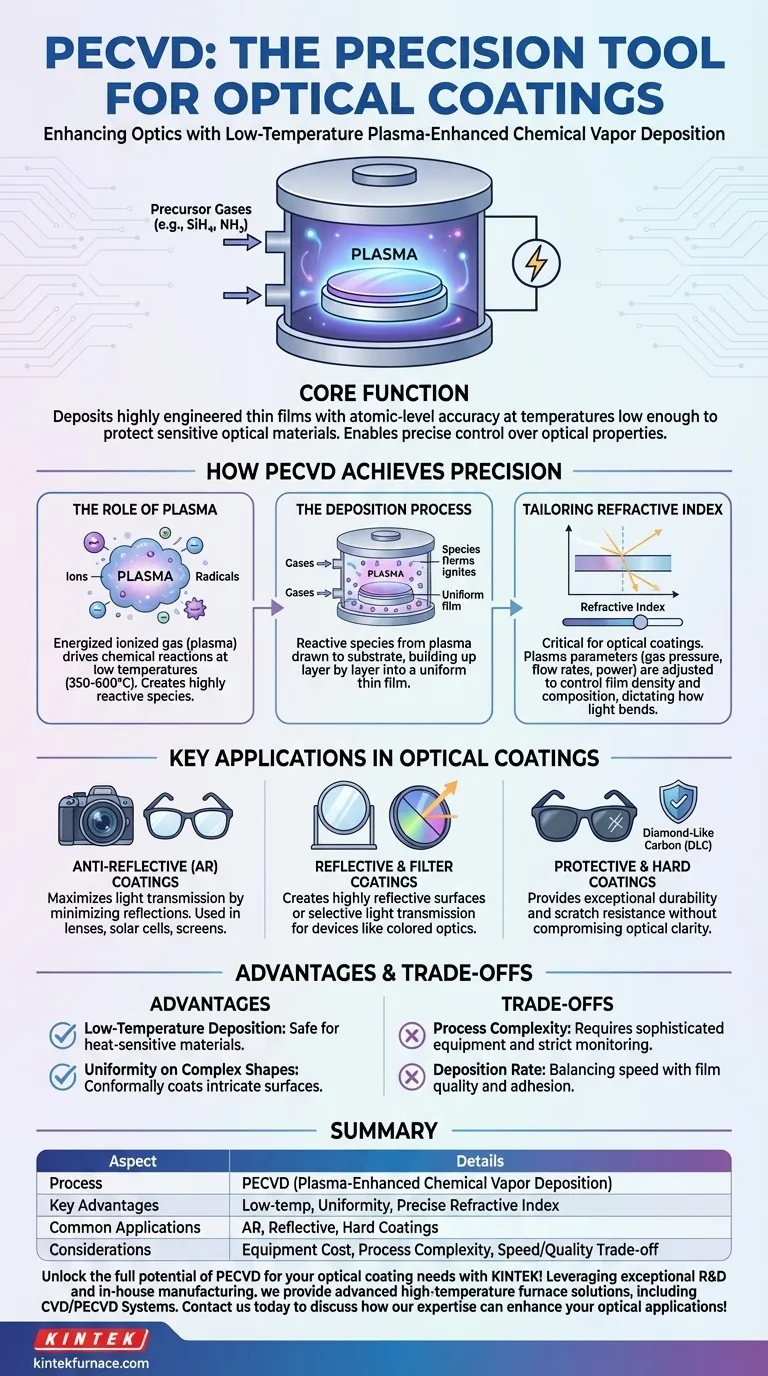

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) serves as a precision tool for depositing highly engineered thin films onto optical components. This process is fundamental to creating coatings that manipulate light, such as anti-reflective layers on lenses, and to enhance the durability of optical surfaces with hard, protective films. By controlling a plasma environment, PECVD allows manufacturers to build these films with atomic-level accuracy at temperatures low enough to protect sensitive optical materials.

The essential role of PECVD in optics is its ability to use low-temperature plasma to create thin films with precisely controlled optical properties. This makes it possible to enhance everything from eyeglasses to advanced sensors without damaging the underlying component.

How PECVD Achieves Precision Optical Control

The power of PECVD lies in its use of plasma to drive chemical reactions that would otherwise require destructive high temperatures. This gives engineers exceptional control over the final film's characteristics.

The Role of Plasma

Plasma, an ionized gas, is the engine of the PECVD process. It is created by applying an electric field to precursor gases inside a vacuum chamber.

This energized plasma contains highly reactive ions and radicals that are ready to form a solid film, significantly lowering the required deposition temperature compared to conventional methods.

The Deposition Process

The process begins by placing the optical component, or substrate, inside a vacuum chamber. Precursor gases, such as silane (SiH4) and ammonia (NH3), are then introduced.

An electric field ignites the gases into a plasma. The reactive species from the plasma are then drawn to the substrate's surface, where they bond and build up layer by layer into a uniform, solid thin film.

Tailoring the Refractive Index

For optical coatings, the refractive index is the most critical property. It dictates how light bends or reflects when it hits the film.

PECVD allows for precise tuning of this property. By adjusting plasma parameters—such as gas pressure, flow rates, and electrical power—engineers can meticulously control the density and chemical composition of the film, thereby setting its exact refractive index.

Key Applications in Optical Coatings

PECVD's versatility enables a wide range of functional coatings that are critical to the performance and longevity of modern optics.

Anti-Reflective (AR) Coatings

Reflections cause light loss and unwanted glare. PECVD is used to deposit single or multiple layers of film with carefully selected refractive indices that cause destructive interference for reflected light waves.

This maximizes light transmission, which is essential for camera lenses, eyeglass lenses, solar cells, and display screens.

Reflective and Filter Coatings

Conversely, PECVD can be used to create highly reflective coatings for mirrors or specialized optical filters.

By stacking layers of materials with alternating high and low refractive indices, specific wavelengths of light can be selectively reflected or transmitted, enabling the creation of colored optical devices.

Protective and Hard Coatings

Optical surfaces, especially those on consumer products like sunglasses, must be durable. PECVD excels at depositing hard, transparent films like Diamond-Like Carbon (DLC).

These coatings provide exceptional wear and scratch resistance without compromising optical clarity. The process is also known for its ability to uniformly coat complex, curved surfaces, which is a common challenge with optical components.

Understanding the Advantages and Trade-offs

No technology is a universal solution. Understanding PECVD's strengths and limitations is key to its effective application.

Advantage: Low-Temperature Deposition

This is PECVD's defining advantage. With typical process temperatures between 350-600 °C, it can safely coat temperature-sensitive materials like polymers or pre-assembled optical devices that would be damaged by high-temperature processes.

Advantage: Uniformity on Complex Shapes

The plasma helps the precursor gases conformally coat intricate and irregular surfaces. This ensures that a lens or mirror with a complex curvature receives a film of consistent thickness and quality across its entire surface.

Consideration: Process Complexity

The power of PECVD comes from its precise control over many variables. This requires sophisticated and expensive equipment, along with rigorous process monitoring of gas flows, pressure, and plasma power to ensure repeatable, high-quality results.

Consideration: Deposition Rate

While PECVD can create thick films, there is often a direct trade-off between deposition speed and film quality. Attempting to accelerate the process too much can introduce internal stress or defects into the film, potentially compromising its optical performance or adhesion.

Applying This to Your Goal

Your specific objective will determine how you leverage PECVD technology.

- If your primary focus is maximum light transmission: You will use PECVD to build multi-layer anti-reflective coatings with precisely graded refractive indices.

- If your primary focus is durability and wear resistance: You will employ PECVD to deposit a hard, transparent coating like Diamond-Like Carbon (DLC) on the outermost surface.

- If your primary focus is coating complex or heat-sensitive optics: PECVD's low-temperature process and excellent conformal coverage make it the definitive choice over higher-temperature alternatives.

By mastering the parameters of the plasma, you gain direct control over the fundamental interaction between light and your material.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses low-temperature plasma for thin film deposition on optical components. |

| Key Advantages | Low-temperature operation (350-600°C), uniform coating on complex shapes, precise control of refractive index. |

| Common Applications | Anti-reflective coatings, reflective/filter coatings, protective hard coatings (e.g., Diamond-Like Carbon). |

| Considerations | Requires sophisticated equipment, process complexity, trade-offs between deposition rate and film quality. |

Unlock the full potential of PECVD for your optical coating needs with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether for anti-reflective layers, durable protective films, or tailored refractive indices. Contact us today to discuss how our expertise can enhance your optical applications and drive innovation in your projects!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings