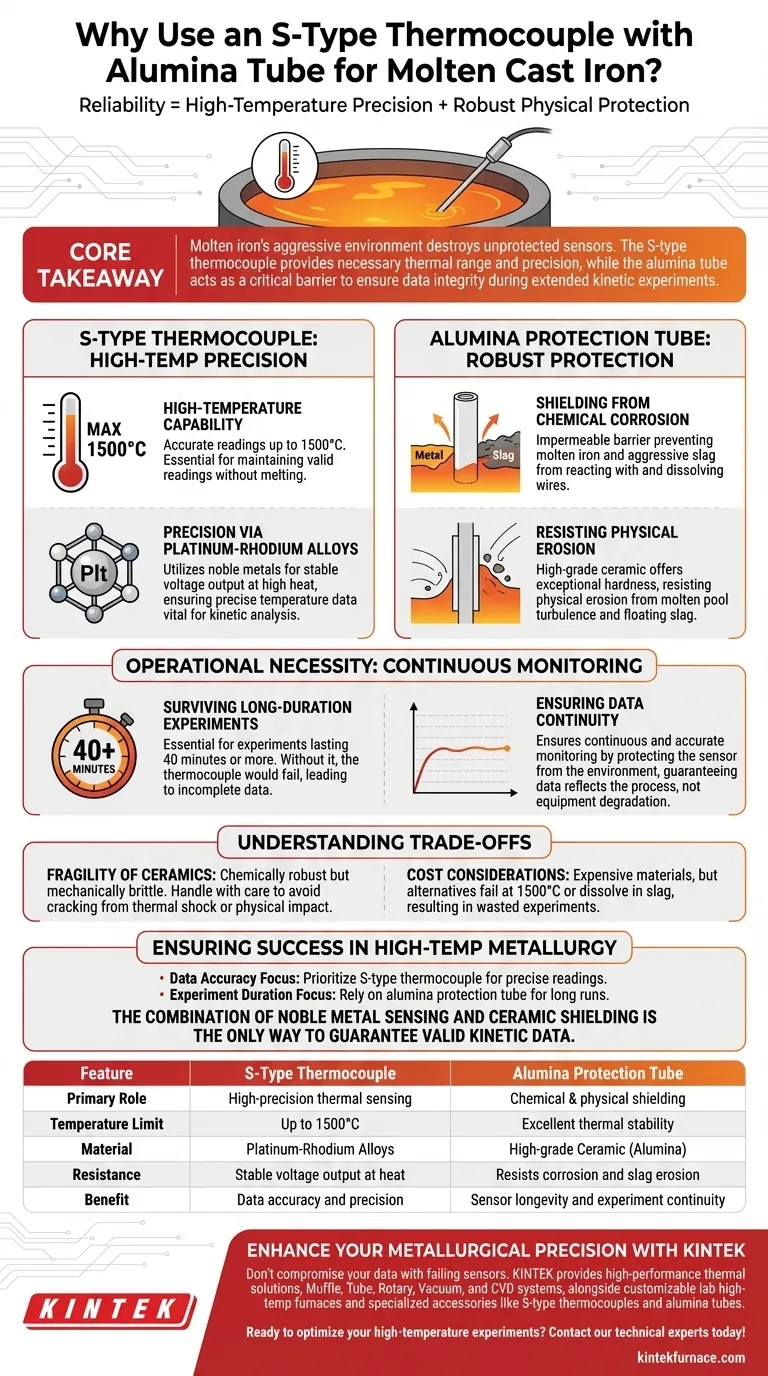

Reliability in molten metal monitoring depends on pairing high-temperature precision with robust physical protection. To successfully monitor molten cast iron pool temperatures, you must use an S-type thermocouple for its ability to withstand 1500°C, combined with an alumina protection tube to shield the fragile wires from chemical and physical destruction.

Core Takeaway Molten iron creates an aggressive environment that destroys unprotected sensors through heat, chemical corrosion, and physical erosion. The S-type thermocouple provides the necessary thermal range and precision, while the alumina tube acts as a critical barrier to ensure data integrity during extended kinetic experiments.

The Role of the S-Type Thermocouple

High-Temperature Capability

Molten cast iron involves extreme temperatures that exceed the limits of standard base-metal thermocouples.

An S-type thermocouple is specifically engineered to function accurately at temperatures up to 1500°C. This capability is essential for maintaining a valid reading without the sensor melting or degrading rapidly.

Precision via Platinum-Rhodium Alloys

The S-type thermocouple utilizes platinum-rhodium alloys in its construction.

These noble metals provide a stable voltage output even at high heat. This stability ensures that the temperature data remains precise, which is vital for analyzing the kinetics of the melt.

Why the Alumina Protection Tube is Critical

Shielding from Chemical Corrosion

Direct contact with molten iron is destructive to thermocouple wires.

The alumina protection tube serves as an impermeable barrier against chemical corrosion. It specifically prevents the molten iron and aggressive desulfurization slag from reacting with and dissolving the platinum-rhodium wires.

Resisting Physical Erosion

The movement of the molten pool can physically wear down sensors.

Alumina is a high-grade ceramic that offers exceptional hardness. It resists the physical erosion caused by the turbulence of the molten iron and the abrasive nature of the floating slag layer.

Operational Necessity: Continuous Monitoring

Surviving Long-Duration Experiments

Kinetic experiments in metallurgy often require data collection over extended periods.

The primary reference notes that these experiments may last 40 minutes or more. Without the protective alumina tube, the thermocouple would likely fail before the experiment concludes, leading to incomplete data.

Ensuring Data Continuity

A failing sensor introduces noise and inaccuracy before it breaks completely.

By protecting the sensor from the environment, the alumina tube ensures continuous and accurate monitoring. This guarantees that the temperature profile recorded reflects the actual process, not the degradation of the equipment.

Understanding the Trade-offs

Fragility of Ceramics

While alumina is chemically robust, it is mechanically brittle.

Operators must handle the protection tubes with care to avoid cracking them due to thermal shock or physical impact before insertion. A cracked tube compromises the entire measurement system.

Cost Considerations

S-type thermocouples and high-purity alumina are expensive materials.

However, using cheaper alternatives is a false economy in this context. Lower-grade sensors will fail at 1500°C, and inferior protection tubes will dissolve in the slag, resulting in wasted experiments.

Ensuring Success in High-Temperature Metallurgy

To achieve reliable results in molten iron studies, align your equipment with your specific experimental needs.

- If your primary focus is Data Accuracy: Prioritize the S-type thermocouple to ensure the platinum-rhodium alloys provide precise readings up to 1500°C.

- If your primary focus is Experiment Duration: Rely on the alumina protection tube to prevent corrosion from slag and iron during runs lasting 40 minutes or longer.

The combination of noble metal sensing and ceramic shielding is the only way to guarantee valid kinetic data in molten iron environments.

Summary Table:

| Feature | S-Type Thermocouple | Alumina Protection Tube |

|---|---|---|

| Primary Role | High-precision thermal sensing | Chemical & physical shielding |

| Temperature Limit | Up to 1500°C | Excellent thermal stability |

| Material | Platinum-Rhodium Alloys | High-grade Ceramic (Alumina) |

| Resistance | Stable voltage output at heat | Resists corrosion and slag erosion |

| Benefit | Data accuracy and precision | Sensor longevity and experiment continuity |

Enhance Your Metallurgical Precision with KINTEK

Don't compromise your data with failing sensors. KINTEK provides high-performance thermal solutions specifically designed for the most aggressive laboratory environments. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable lab high-temp furnaces and specialized accessories like S-type thermocouples and alumina tubes to meet your unique research needs.

Ready to optimize your high-temperature experiments? Contact our technical experts today to find the perfect customizable solution for your lab!

Visual Guide

References

- Ida B. G. S. Adhiwiguna, Rüdiger Deike. Observation on Reaction Mechanism of Lime Powder as Desulfurization Agent for Molten Cast Iron. DOI: 10.1002/srin.202500052

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why are multiple sets of resistance heaters used in varying positions for calorimeter calibration? Ensure Spatial Accuracy

- What does SC Type refer to in Silicon Carbide Heating Elements? Discover Its Uniform Heat Benefits

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- How does a ceramic heater generate heat? Discover the Safe, Efficient PTC Technology

- What is the service life of MoSi2 heating elements and how do they perform in chemical environments? Maximize Longevity with Proper Use

- What makes ceramic heating elements more energy-efficient than metal alternatives? Superior Insulation & Uniform Heat Distribution

- What industries commonly use MoSi2 heating elements? Essential for High-Temp Glass, Ceramics, and Metals

- What are the advantages of using MoSi2 heating elements? Achieve High-Temperature Reliability and Efficiency